Horizontal Split Case Pump

Product Description

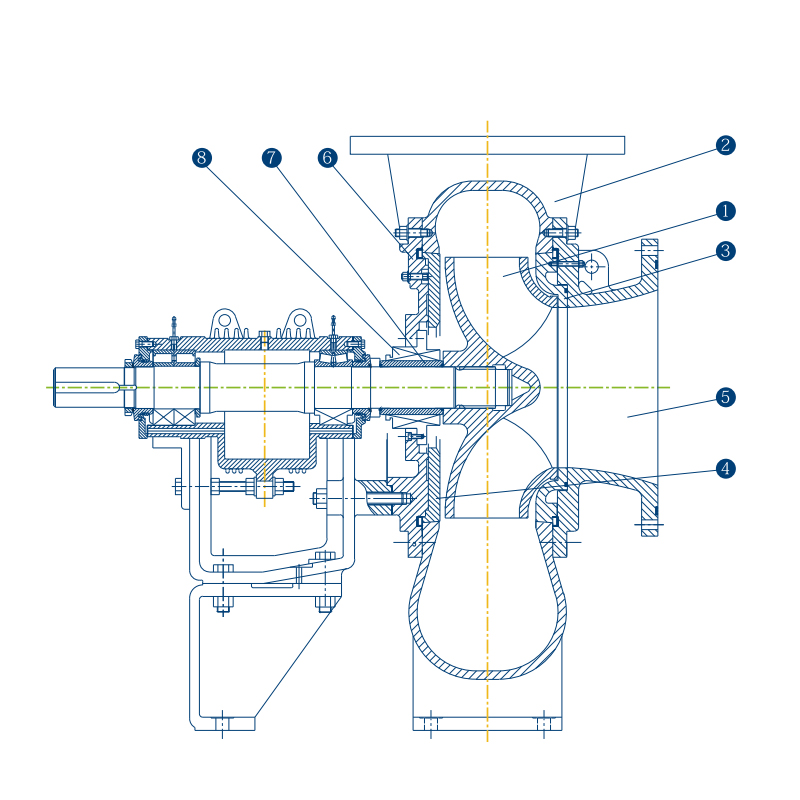

Introducing the S/SH serial single stage double-suction centrifugal pump, a high-performance pump with exceptional head and flow characteristics. This pump is widely used in various engineering applications, making it a versatile solution for a range of projects.

With its late-model energy-saving design, this horizontally split pump is a new and improved version of the traditional double suction pump. It is the result of our dedication to innovation and our commitment to meeting the needs of our customers.

One of the key features of this pump is its construction, which can be customized to suit your specific requirements. Choose from materials such as cast iron, duct alloy, carbon steel, zinc-free bronze, silicon brass, or stainless steel. We also offer other materials on request, ensuring that the pump is tailored to your project's needs.

The high efficiency double suction impeller is another standout feature of this pump. It ensures optimal performance and efficient operation, helping to maximize the pump's capabilities.

Durability and longevity are also key considerations in the design of this pump. It features a low noise, long life bearing, which contributes to its overall reliability and helps to reduce maintenance costs.

We understand the importance of a reliable mechanical seal, and that is why this pump comes equipped with a premium quality mechanical seal. This seal helps to prevent leaks and ensures smooth and efficient operation of the pump.

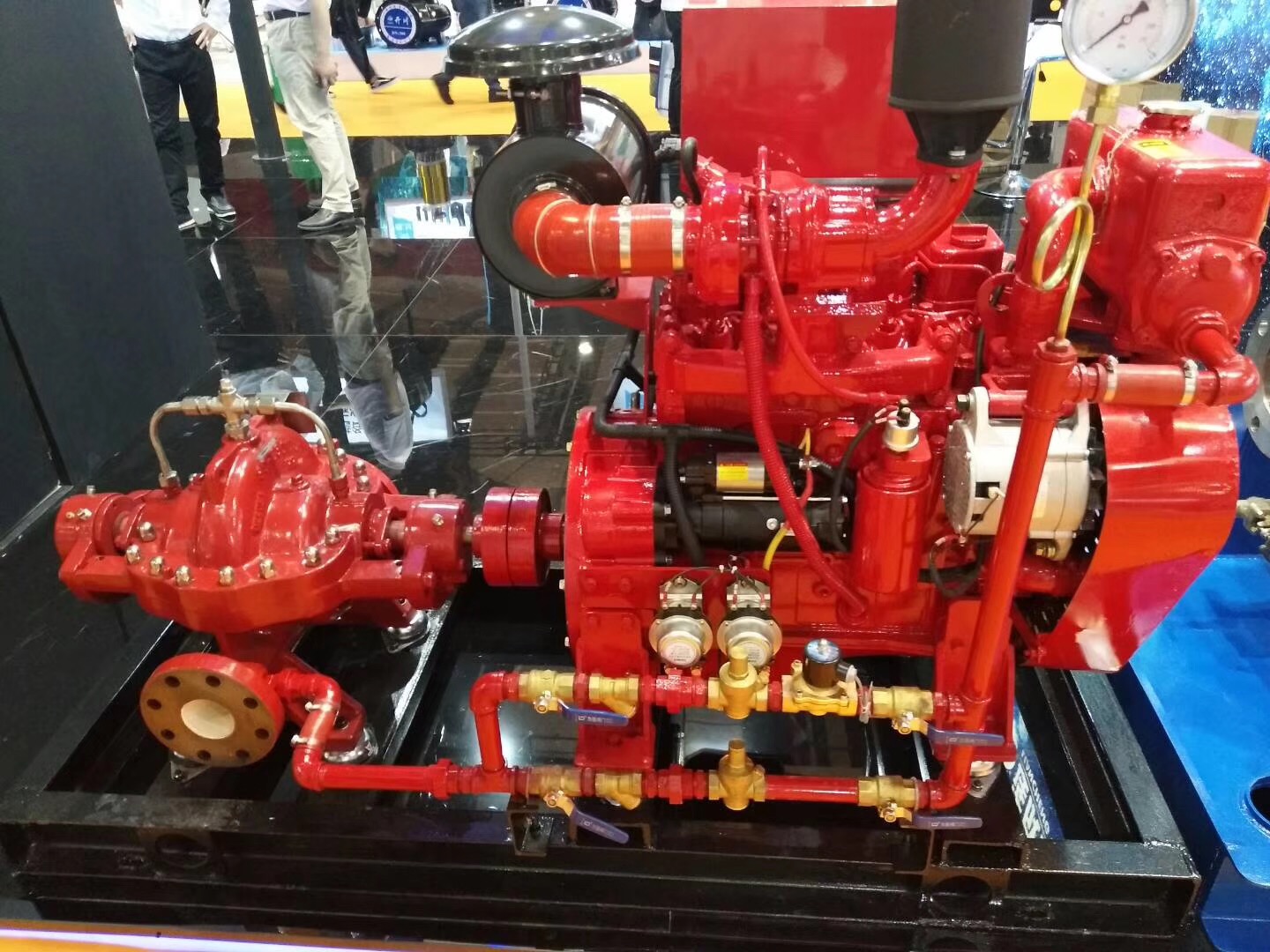

Whether you prefer an electric or diesel drive, this pump can be adapted to suit your power source requirements. This flexibility makes it suitable for a range of applications and ensures that it can be integrated seamlessly into your project.

Overall, the S/SH serial single stage double-suction centrifugal pump is a superior choice for engineers looking for a high performance and versatile pump solution. Its energy-saving design, customizable construction, and durable components make it a reliable and efficient option for any project.

Performance range

Flow: 112 ~ 6460m / h

Head: 9 ~ 140m

Motor power: 18.5 ~ 850kW

parameter

| Model | Flow | Head | Speed | Power | Outlet diam. | Caliber | |

| m3/h | m | r/min | KW | mm | In | Out | |

| 6SH-6 150S78 |

126 162 198 |

84 78 70 |

2950 | 40 46.5 52.4 |

55 | 150 | 100 |

| 6SH-6A 150S78A |

111.6 144 180 |

67 62 55 |

2950 | 30 33.8 38.5 |

45 | 150 | 100 |

| 6SH-9 150S50 |

130 170 220 |

52 47.6 35 |

2950 | 25.3 27.6 31.3 |

37 | 150 | 100 |

| 6SH-9A 150S50A |

111.6 144 180 |

43.8 40 35 |

2950 | 25.3 27.6 31.3 |

37 | 150 | 100 |

| 8SH-6 200S95A |

180 234 288 |

100 93.5 82.5 |

2950 | 68 79.5 86.4 |

110 | 200 | 125 |

| 8SH-6A 200S95 |

180 270 324 |

88 83 77 |

2950 | 60.6 67.5 76.2 |

90 | 200 | 125 |

| 8SH-9 200S963 |

216 268 351 |

69 62.5 50 |

2950 | 55 61.6 67.8 |

75 | 200 | 125 |

| 8SH-9A 200S63A |

180 270 324 |

54.5 46 37.5 |

2950 | 41 48.3 51 |

55 | 200 | 125 |