Iphampu yepayipi

Incazelo Yomkhiqizo

Amaphampu amaphakathi e-ISG aklanywe ngobuhlakani ngesisekelo samaphampu aqondile ajwayelekile ngokuhlanganyela yizisebenzi zethu zesayensi nezobuchwepheshe ezinochwepheshe bephampu ekhaya.

Basebenzisa imodeli ye-hydraulic ethuthukisiwe yasekhaya kanye nemingcele yokusebenza yamaphampu angu-IS centrifugal. Ngokomehluko wezinga lokushisa lesevisi, elimaphakathi nezimo njll.,

Amaphampu amaphakathi e-ISG aklanywe ngobuhlakani ngesisekelo samaphampu aqondile ajwayelekile ngokuhlanganyela ngabasebenzi bethu besayensi nezobuchwepheshe abanochwepheshe bephampu ekhaya. Basebenzisa imodeli ye-hydraulic ethuthukisiwe yasekhaya kanye nemingcele yokusebenza yamaphampu ayi-IS centrifugal. umehluko kumazinga okushisa esevisi, amaphakathi nezimo njll., kube namaphampu amanzi ashisayo, amaphampu okushisa aphezulu, amaphampu amakhemikhali avimbela ukubola, amaphampu kawoyela, amaphampu amakhemikhali angaqhumi kanye namaphampu anejubane eliphansi athathwe ku-ISG.

Ifaka ukusebenza kahle okuphezulu, ukongiwa kwamandla, umsindo ophansi nokusebenza okuzinzile njll., lolu chungechunge lwemikhiqizo luhambisana nezinga lakamuva le-JB/T53058-90 elikhishwe uMnyango Wezemishini, i-PRChina, futhi iklanywe futhi yakhiwe ngezinga le-ISO2858.

Izici

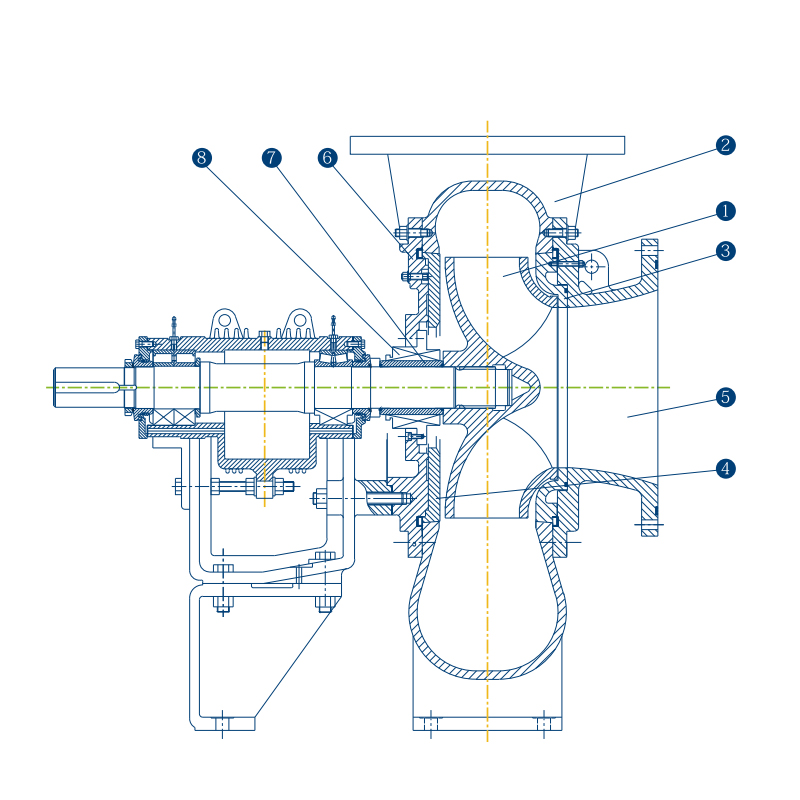

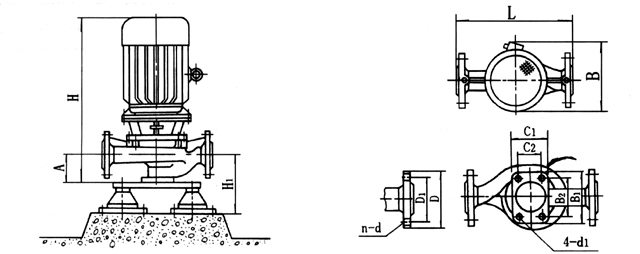

1.Isakhiwo esimile, indawo yokungena kanye ne-outlet zinosayizi ofanayo futhi kumugqa ofanayo ophakathi nendawo, zingafakwa epayipini, njengoba kwenza ivalvu, ukubukeka okuhlangene nokukhangayo, indawo encane yokuhlala, izindleko eziphansi zokwakha, isevisi yangaphandle uma ihlinzekwe ikhava yokuvikela.

I-2.I-Impeller ifakwe ngokuqondile ku-shaft enwetshiwe ye-motor, izilinganiso ezimfushane ze-axial, isakhiwo esihlangene, nokucushwa okunengqondo kwepompo kanye ne-motor bear ukuze kusebenze ukulinganisa umthwalo we-radial kanye ne-axial okhiqizwa ukusebenza kwepompo, ngaleyo ndlela kuqinisekiswe ukusebenza kahle, ukudlidliza okuncane nokuphansi. umsindo.

3. Ukusetshenziswa kophawu lwemishini noma inhlanganisela yophawu lwemishini yokufaka uphawu lwe-shaft, indandatho yokuvalwa kwe-titanium alloy evela kwamanye amazwe, izinga lokushisa eliphakathi nendawo elimelana nophawu lomshini, i-hard alloy material kanye nokugqoka kophawu olungazweli, okwandisa ngempumelelo impilo yesevisi yophawu lwemishini.

I-4.Ukufakwa okulula nokugcinwa, asikho isidingo sokuhlukanisa uhlelo lwamapayipi, futhi zonke izingxenye ze-rotor zingakhishwa kuphela ngokukhipha amantongomane esihlalweni sobumbano sepompo.

5.Amamodi ochungechunge nokugijima okuhambisanayo okuphendula izinga lokugeleza nekhanda lokulethwa elidingekayo.

6.Kufakwe ngokuqondile nangokuvundlile ngokwezidingo zokuhlelwa kwamapayipi.

1.Suction pressure ≤ 1.0MPa, or the maximum working pressure of pump system ≤ 1.6MPa, pump static test pressure at 2.5MPa. Please specify the working pressure of the system when placing an order. To acquire working pressure of pump system greater than 1.6MPa should be specified separately when placing an order for our convenience to use cast steel for wetted parts and connection parts in production.

2.Ambient temperature <40°C,relative humidity <96%.

3.Volume content of solid particels in medium to be delivered shouldn’t exceed 0.1% of unit volume, granularity <0.2mm.

Qaphela: ukuze uphathe izinhlayiya ezincane eziphethe okuphakathi, sicela usho lapho ufaka i-oda ukuze kube lula ngathi ukusebenzisa uphawu lomshini oluqinile.