Uzbek

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Avg . 16, 2025 07:25 Back to list

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

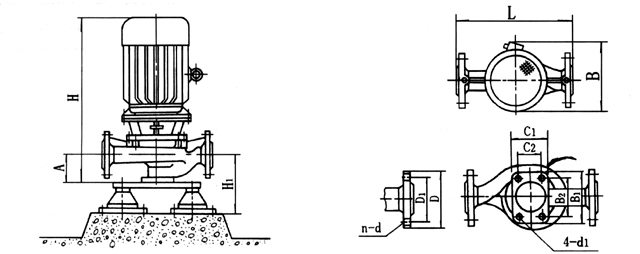

The ISG series vertical pipeline pump represents a cutting-edge solution in the field of industrial fluid management. Engineered by Chi Yuan Pumps Co., LTD., this pump series combines innovative design, advanced technology, and robust performance to meet the diverse needs of modern industries. This article delves into the features, technical specifications, applications, and the company's commitment to excellence, providing a comprehensive overview of the ISG series.

Overview of the ISG Series Vertical Pipeline Pump

The ISG series is a single-stage, single-suction piping centrifugal pump designed to operate efficiently in a wide range of industrial environments. Developed through collaboration between Chi Yuan Pumps Co., LTD.'s technical team and domestic pump experts, the ISG series incorporates advanced hydraulic models and performance parameters derived from the IS centrifugal pump. This pump series is versatile, with variants such as hot water pumps, high-temperature pumps, corrosion-resistant chemical pumps, oil pumps, explosion-proof chemical pumps, and low-speed pumps tailored to specific operational requirements.

Key Features of the ISG Series

The ISG series is distinguished by its exceptional performance and user-friendly design. Here are some of its standout features:

- Vertical Structure: The pump's vertical design allows it to be mounted directly in pipelines, similar to a valve, reducing the need for complex installation systems. This compact structure minimizes floor space requirements and lowers construction costs. Outdoor operation is feasible with the addition of a protective cover.

- Efficient Impeller Configuration: The impeller is directly mounted on the motor's extended shaft, resulting in a short axial dimension and a compact structure. This design ensures a reasonable configuration of the pump and motor bearings, effectively balancing radial and axial loads during operation, which leads to smooth operation, minimal vibration, and low noise levels.

- Advanced Sealing Technology: The ISG series employs mechanical seals or combinations of mechanical seals, imported titanium alloy sealing rings, intermediate high-temperature resistant mechanical seals, and hard alloy materials. These components enhance the pump's durability and extend the service life of the mechanical seal.

- Easy Maintenance: The pump's design allows for easy installation and maintenance. Users can remove all rotor components without disassembling the pipeline system by simply unscrewing the nuts on the union seat of the pump.

- Flexible Operation Modes: The series supports both series and parallel running modes, adapting to varying flow rate and delivery head requirements. This flexibility ensures optimal performance in diverse applications.

- Installation Versatility: The ISG series can be installed vertically or horizontally, depending on the pipeline arrangement, offering greater adaptability to different industrial settings.

Technical Specifications

The ISG series is engineered to meet rigorous industrial standards, ensuring reliability and efficiency. Below is a detailed specification table:

| Parameter | Specification |

|---|---|

| Maximum Suction Pressure | ≤ 1.0 MPa |

| Maximum Working Pressure | ≤ 1.6 MPa |

| Static Test Pressure | 2.5 MPa |

| Ambient Temperature | ≤ 40°C |

| Relative Humidity | ≤ 96% |

| Solid Particle Content | ≤ 0.1% by volume |

| Particle Granularity | ≤ 0.2 mm |

| Compliance Standards | JB/T 53058-90 (China), ISO 2858 |

Working Conditions and Application Scenarios

The ISG series is designed to operate under a wide range of conditions, making it suitable for various industrial applications. Key working conditions include:

- Pressure Requirements: The pump can handle suction pressures up to 1.0 MPa and system pressures up to 1.6 MPa. For systems requiring higher pressure, users must specify this during ordering to ensure the use of cast steel for wetted parts and connections.

- Environmental Factors: The pump operates efficiently in ambient temperatures below 40°C and humidity levels under 96%. It is suitable for both indoor and outdoor environments, provided appropriate protective measures are in place.

- Material Compatibility: The ISG series can handle media with solid particles up to 0.1% by volume and particle sizes less than 0.2 mm. For applications involving small particles, users should specify this requirement to ensure the use of wear-resistant mechanical seals.

The ISG series is widely used in industries such as chemical processing, water treatment, HVAC systems, and power generation. Its versatility allows it to handle water, oils, and corrosive chemicals, making it an essential component in diverse industrial settings.

Company Background: Chi Yuan Pumps Co., LTD.

Chi Yuan Pumps Co., LTD. is a leading manufacturer of industrial pumps, dedicated to providing high-quality solutions for fluid management. With a focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. The ISG series is a testament to Chi Yuan Pumps' commitment to excellence, combining advanced technology with practical design to meet the evolving needs of modern industries.

Why Choose the ISG Series?

The ISG series offers several advantages that make it an ideal choice for industrial applications:

- Energy Efficiency: The pump's advanced hydraulic design and efficient motor configuration ensure minimal energy consumption while maintaining high performance.

- Low Noise Operation: The optimized bearing configuration and compact structure reduce vibration and noise, creating a quieter working environment.

- Reliability and Durability: The use of high-quality materials and advanced sealing technology ensures long service life and minimal maintenance requirements.

- Customization Options: Chi Yuan Pumps offers tailored solutions to meet specific operational needs, including variants for high-temperature, corrosive, and explosive environments.

- Compliance with International Standards: The ISG series adheres to the latest industry standards, ensuring product reliability and safety. According to the National Institute of Standards and Technology (NIST), compliance with international standards is critical for ensuring product performance and interoperability in global markets (NIST, 2023).

Applications of the ISG Series

The ISG series is designed to handle a wide range of fluids and applications, including:

- Water Supply Systems: Ideal for municipal water supply, fire protection, and irrigation systems due to its high efficiency and reliability.

- Chemical Processing: The corrosion-resistant variants are suitable for handling aggressive chemicals in chemical plants and laboratories.

- Oil and Gas Industry: The oil pump variant is designed to transport lubricants and fuels efficiently in industrial settings.

- HVAC Systems: The pump's low noise and energy-efficient operation make it an excellent choice for heating, ventilation, and air conditioning systems.

- Power Generation: The high-temperature and explosion-proof variants are used in power plants for cooling and other critical applications.

Conclusion

The ISG series vertical pipeline pump by Chi Yuan Pumps Co., LTD. is a versatile, efficient, and reliable solution for industrial fluid management. With its advanced design, compliance with international standards, and adaptability to various operational conditions, the ISG series is an essential asset for modern industries. Whether handling water, chemicals, or oils, the ISG series delivers exceptional performance, ensuring smooth and efficient operations in diverse environments.

References

National Institute of Standards and Technology (NIST). (2023). Standards for Industrial Equipment. Retrieved from https://www.nist.gov

This is the last article

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.16,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving

NewsAug.16,2025

-

Heavy-Duty Wear-Resistant Slurry Pumps for Mining & Industrial Sludge

NewsAug.16,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD. | High Efficiency, Low Noise, Durable Design

NewsAug.16,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps|High Efficiency, Energy Saving, Low Noise

NewsAug.15,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficient, Compact Design

NewsAug.15,2025