Tajik

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 01, 2025 00:00 Back to list

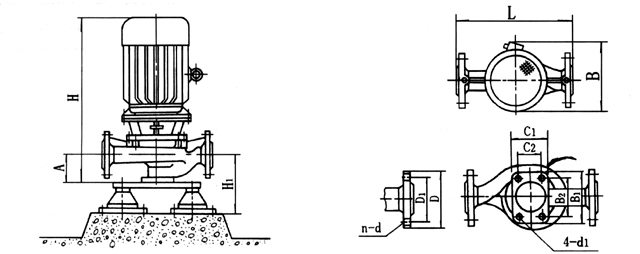

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

The ISG series vertical pipeline pump represents a pinnacle of innovation in fluid dynamics and industrial pumping technology. Designed by Chi Yuan Pumps Co., Ltd., this series of single-stage, single-suction centrifugal pumps is engineered to meet the diverse demands of modern industrial applications. With a focus on efficiency, durability, and adaptability, the ISG series has become a trusted solution for industries ranging from chemical processing to water treatment. This article delves into the product's features, technical specifications, applications, and the company's commitment to quality, while also referencing the importance of standards like those established by the National Institute of Standards and Technology (NIST).

Company Background: Chi Yuan Pumps Co., Ltd.

Founded with a mission to deliver cutting-edge pumping solutions, Chi Yuan Pumps Co., Ltd. has established itself as a leader in the design and manufacturing of high-performance pumps. The company's expertise lies in combining advanced hydraulic modeling with rigorous quality control to produce pumps that meet the highest industry standards. By collaborating with both in-house technical personnel and external pump experts, Chi Yuan Pumps ensures that its products are not only innovative but also aligned with global engineering practices. The ISG series is a testament to this commitment, reflecting the company's dedication to creating reliable, energy-efficient, and user-friendly pumping systems.

Product Overview: The ISG Series Vertical Pipeline Pump

The ISG series is a vertical pipeline pump that smartly integrates the principles of traditional vertical pumps with modern engineering advancements. Unlike conventional pumps, the ISG series is designed to be installed directly within a pipeline, functioning much like a valve. This unique design minimizes the need for complex installation processes and reduces the overall footprint of the system. The pump's compact structure, combined with its high efficiency and low noise operation, makes it an ideal choice for applications where space and operational quietness are critical.

The ISG series is not a one-size-fits-all solution. It has evolved into a family of pumps tailored to specific operational conditions. For instance, the hot water pump variant is designed for high-temperature environments, while the anticorrosion chemical pump is engineered to handle aggressive chemical media. Other specialized versions include the oil pump, explosion-proof chemical pump, and low-speed pump, each addressing unique challenges in industrial settings. This versatility ensures that the ISG series can adapt to a wide range of applications, from municipal water supply systems to industrial process control.

Key Features of the ISG Series

The ISG series is distinguished by its innovative design and robust performance. Here are some of its standout features:

1. Vertical Structure for Space Efficiency

The pump's vertical structure allows for seamless integration into existing pipeline systems. With both the inlet and outlet ports aligned on the same centerline, the ISG series can be mounted like a valve, eliminating the need for additional support structures. This design not only saves space but also reduces installation costs. The compact footprint is particularly beneficial in facilities with limited floor space, such as chemical plants and water treatment centers.

2. Direct Motor Shaft Connection for Enhanced Stability

The impeller is directly mounted on the extended shaft of the motor, resulting in a shorter axial dimension and a more compact configuration. This design minimizes the risk of radial and axial load imbalances, which are common in traditional pumps. The optimized bearing configuration ensures smooth operation, reducing vibration and noise levels. This feature is especially valuable in environments where noise pollution is a concern, such as residential areas or laboratories.

3. Advanced Shaft Sealing Technologies

The ISG series employs mechanical seals or mechanical seal combinations to prevent leakage. The use of imported titanium alloy sealing rings, intermediate high-temperature resistant mechanical seals, and hard alloy materials significantly extends the service life of the pump. These advanced sealing technologies are critical in applications involving corrosive or high-temperature media, where traditional seals might fail prematurely.

4. Easy Maintenance and Installation

One of the most notable advantages of the ISG series is its ease of maintenance. Unlike conventional pumps that require the entire pipeline system to be disassembled for repairs, the ISG series allows all rotor components to be removed by simply unscrewing the nuts on the union seat. This design reduces downtime and maintenance costs, making it a cost-effective solution for industrial operators.

5. Flexible Operation Modes

The ISG series supports both series and parallel operation modes, enabling it to meet varying flow rate and head requirements. This flexibility is crucial in applications where system demands fluctuate, such as in HVAC systems or irrigation networks. The ability to adjust the pump's operation mode ensures optimal performance and energy efficiency.

6. Versatile Installation Options

The pump can be installed either vertically or horizontally, depending on the pipeline arrangement. This versatility allows engineers to design systems that maximize space utilization and operational efficiency. For outdoor installations, the inclusion of a protection cover ensures that the pump remains functional even in harsh environmental conditions.

Technical Specifications: A Detailed Overview

The ISG series is engineered to deliver exceptional performance across a wide range of operating conditions. Below is a table summarizing the key technical specifications of the pump:

| Parameter | Specification |

|---|---|

| Model | ISG Series |

| Flow Rate | 1.5 - 120 m³/h |

| Head | 5 - 125 m |

| Power | 0.55 - 55 kW |

| Maximum Working Pressure | 1.6 MPa (2.5 MPa for static test) |

| Temperature Range | -10°C to 150°C |

| Material of Construction | Cast iron, stainless steel, or custom alloys |

| Sealing Type | Mechanical seal with titanium alloy rings |

| Installation Type | Vertical or horizontal |

Applications: Diverse Industrial Uses

The ISG series is designed to address the needs of various industries, making it a versatile solution for fluid transfer. Some of the key applications include:

- Water Supply Systems: The pump is ideal for municipal and industrial water supply systems, where its compact design and high efficiency ensure reliable performance.

- Heating, Ventilation, and Air Conditioning (HVAC): The ISG series is commonly used in HVAC systems to circulate water or other cooling media efficiently.

- Chemical Processing: With its corrosion-resistant variants, the pump is well-suited for handling aggressive chemical media in industrial processes.

- Oil and Gas: The oil pump variant is designed to handle viscous fluids and operate under challenging conditions in the oil and gas sector.

- Wastewater Treatment: The pump's ability to handle solids and its durable construction make it a reliable choice for wastewater treatment plants.

Working Conditions and Safety Considerations

To ensure optimal performance and safety, the ISG series must be operated within specified working conditions:

- Maximum Suction Pressure: ≤ 1.0 MPa

- Maximum Working Pressure: ≤ 1.6 MPa (2.5 MPa for static test)

- Ambient Temperature:

- Relative Humidity:

- Solid Particle Content: ≤ 0.1% by volume (granularity

Operators are advised to specify the working pressure and any special requirements, such as handling solid particles, when placing an order. This ensures that the pump is manufactured with appropriate materials, such as cast steel for wetted parts, to withstand demanding conditions.

NIST Standards and the Importance of Quality Assurance

The design and performance of pumps like the ISG series are closely aligned with industry standards, including those established by the National Institute of Standards and Technology (NIST). While the specific NIST standards for centrifugal pump design may not be directly referenced in the context, NIST plays a critical role in developing and maintaining measurement standards that underpin the reliability and efficiency of industrial equipment. According to NIST, "Standards allow technology to work seamlessly and help commerce happen fairly" (NIST). This principle extends to pump manufacturing, where adherence to standardized measurements ensures interoperability, safety, and performance consistency across global markets.

Chi Yuan Pumps Co., Ltd. incorporates these standards into its production processes, ensuring that the ISG series meets the highest quality benchmarks. By following guidelines such as the ISO 2858 standard and JB/T 53058-90, the company guarantees that its products are not only compliant but also capable of delivering long-term value to customers.

Conclusion: A Reliable Solution for Modern Industrial Needs

The ISG series vertical pipeline pump is a testament to the synergy between advanced engineering and practical design. With its compact structure, high efficiency, and adaptability, it addresses the evolving demands of industrial fluid handling. Whether in water treatment, chemical processing, or HVAC systems, the ISG series offers a reliable and cost-effective solution. Chi Yuan Pumps Co., Ltd.'s commitment to quality, combined with its alignment with international standards, ensures that the ISG series remains a trusted choice for industries worldwide.

For more information about the ISG series and other products from Chi Yuan Pumps Co., Ltd., visit the company's official website. Explore the ISG series product page to discover how this innovative pump can enhance your operations.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/

2. Chi Yuan Pumps Co., Ltd.. Retrieved from https://www.cypump.com

3. ISG Series Vertical Pipeline Pump. Retrieved from https://www.cypump.com/isg-series-vertical-pipeline-pump.html

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025