Basque

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Abu . 18, 2025 11:27 Back to list

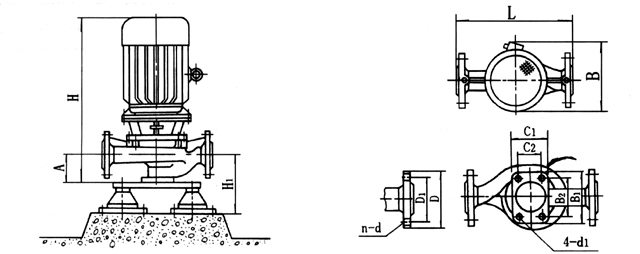

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

The ISG series vertical pipeline pump represents a cutting-edge solution in fluid dynamics, engineered to meet the rigorous demands of modern industrial and commercial applications. Developed through collaborative efforts between the company's technical team and pump experts, this series combines advanced hydraulic modeling with industry-standard compliance to deliver unparalleled performance. This article delves into the product's features, technical specifications, applications, and the company's commitment to innovation.

Key Takeaways:

- Advanced hydraulic design for high efficiency and energy conservation

- Compliance with international standards (ISO 2858, JB/T53058-90)

- Customizable options for diverse operating conditions

- Compact vertical structure for space-saving installations

- Robust mechanical seals for extended service life

Product Overview

The ISG series vertical pipeline pump is a single-stage, single-suction centrifugal pump designed to integrate seamlessly into pipeline systems. Unlike traditional vertical pumps, its innovative design allows it to function as a "valve-like" component, reducing the need for complex installation procedures. This series is particularly notable for its adaptability, with specialized variants such as hot water pumps, high-temperature pumps, corrosion-resistant chemical pumps, oil pumps, and explosion-proof chemical pumps, all derived from the ISG platform.

According to the National Institute of Standards and Technology (NIST), "pump systems account for nearly 20% of industrial energy consumption, emphasizing the importance of energy-efficient designs in reducing operational costs and environmental impact." The ISG series addresses this challenge through its advanced hydraulic model, which optimizes flow efficiency while minimizing energy waste.

Key Features and Advantages

Engineered to exceed industry expectations, the ISG series offers a suite of features that enhance performance, durability, and user convenience:

1. Vertical Structure with Integrated Design

The vertical structure of the ISG pump ensures that the inlet and outlet are aligned on the same centerline, enabling direct pipeline mounting. This design not only saves space but also reduces construction costs, making it ideal for applications with limited floor space. As noted in the NIST technical standards, "compact designs are critical for optimizing industrial infrastructure layouts."

2. High Efficiency and Low Noise Operation

With an energy-saving design, the ISG series achieves high efficiency while maintaining low noise levels. The pump's compact structure and optimized bearing configuration effectively balance radial and axial loads, ensuring smooth operation and minimal vibration. This makes it suitable for environments where noise reduction is a priority, such as residential areas or sensitive industrial zones.

3. Advanced Sealing Technology

The pump employs mechanical seals or combinations of mechanical seals, featuring imported titanium alloy sealing rings and high-temperature resistant materials. These components enhance the pump's resistance to wear and tear, significantly extending its service life. For applications involving corrosive media, the company recommends specifying the use of wear-resistant seals during ordering.

4. Easy Maintenance and Installation

One of the standout features of the ISG series is its user-friendly maintenance design. The rotor components can be removed without disassembling the entire pipeline system, reducing downtime and maintenance costs. This is particularly beneficial in continuous operation environments where system availability is critical.

5. Flexible Operation Modes

The ISG series supports both series and parallel operation modes, allowing it to adapt to varying flow rate and head requirements. This flexibility ensures optimal performance in diverse applications, from water supply systems to chemical processing plants.

Technical Specifications

The ISG series is available in multiple configurations to meet specific operational needs. Below is a detailed overview of its technical parameters:

| Parameter | Specification |

|---|---|

| Model | ISG 50-160, ISG 80-160, ISG 100-160 |

| Flow Rate | 12.5-125 m³/h |

| Head | 20-125 m |

| Power | 1.1-55 kW |

| Efficiency | 65-80% |

| Working Pressure | ≤1.6 MPa (with optional cast steel components for higher pressures) |

| Temperature Range | -10°C to 100°C (with specialized variants for extreme conditions) |

| Material | Cast iron, stainless steel, or custom alloys based on application |

Applications and Use Cases

The versatility of the ISG series makes it suitable for a wide range of applications, including:

- Water Supply Systems: Ideal for municipal and industrial water distribution, where reliability and efficiency are paramount.

- Heating and Cooling Systems: Used in HVAC systems for circulating hot or cold water, ensuring consistent temperature control.

- Chemical Processing: Corrosion-resistant variants are employed in handling aggressive chemicals, maintaining system integrity.

- Oil and Gas Industry: Specialized oil pumps handle viscous fluids, while explosion-proof models ensure safety in hazardous environments.

- Construction and Agriculture: High-head configurations are used for irrigation and drainage systems, adapting to varying terrain.

As highlighted in NIST research, "pump systems must be tailored to specific operational conditions to maximize efficiency and longevity." The ISG series exemplifies this principle through its customizable design and robust construction.

Company Background: 驰元泵业(河北)有限公司

Founded as a leader in pump technology, Chi Yuan Pumps Co., LTD. has established itself as a trusted provider of high-quality fluid handling solutions. With a focus on innovation and customer satisfaction, the company combines advanced engineering with rigorous quality control to deliver products that meet global standards.

The company's commitment to excellence is reflected in its adherence to international standards such as ISO 2858 and JB/T53058-90. By collaborating with industry experts and leveraging cutting-edge technology, Chi Yuan Pumps continues to set benchmarks in the pump manufacturing sector.

Conclusion

The ISG series vertical pipeline pump stands as a testament to engineering innovation and practical design. Its combination of efficiency, durability, and adaptability positions it as a preferred choice for a wide array of applications. Whether in water supply, chemical processing, or industrial HVAC systems, the ISG series delivers reliable performance that meets the demands of modern infrastructure.

For more information about the ISG series or to explore other products from Chi Yuan Pumps Co., LTD., visit their official website. The company's dedication to quality and customer-centric solutions ensures that their products remain at the forefront of fluid dynamics technology.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

Keywords: pipeline pump, pipeline pump station, satisfactory pipeline pump, splash fun pipeline pumper, pipeline pump station design

This is the last article

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsAug.18,2025

-

pipeline pump-Chi Yuan Pumps Co., LTD.|High Efficiency,Low Noise

NewsAug.18,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.18,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|Energy Efficiency&Durability

NewsAug.18,2025

-

Large Wear-Resistant Slurry Pumps for Mining & Industrial Sludge

NewsAug.18,2025

-

pipeline pump-Chi Yuan Pumps Co., LTD.|Industrial Fluid Management&High Efficiency

NewsAug.17,2025