Yiddish

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Oct . 10, 2024 02:43 Back to list

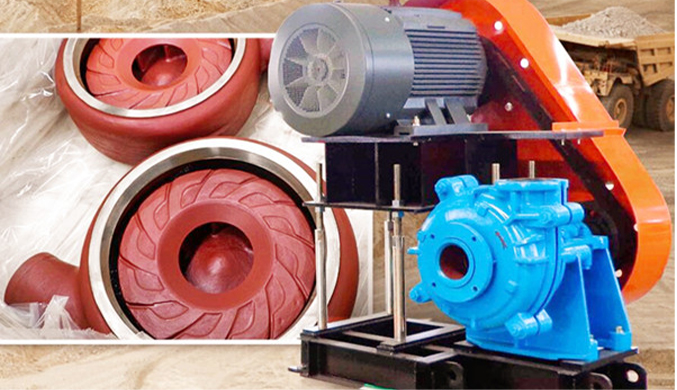

Compact Centrifugal Pump for Efficient Slurry Handling and Transport Solutions

The Importance of Small Centrifugal Slurry Pumps in Industry

Small centrifugal slurry pumps play a significant role in various industrial applications, especially in processes that require the efficient transfer of slurries containing solid particles. These pumps are designed to handle mixtures of liquids and solids, making them ideal for sectors such as mining, dredging, and wastewater treatment.

One of the primary advantages of small centrifugal slurry pumps is their ability to manage complex materials. In industries like mining, slurries often consist of abrasive particles, which can be challenging to transport. However, these pumps are engineered to withstand such conditions, featuring wear-resistant materials that enhance their longevity and reliability. This durability not only reduces maintenance costs but also minimizes downtime, ensuring that operations run smoothly.

Additionally, small centrifugal slurry pumps are relatively compact compared to their larger counterparts. Their size makes them versatile for use in tight spaces where larger pumps cannot fit. This compactness does not compromise performance; in fact, many small models offer impressive flow rates and pressure capabilities, making them suitable for a wide range of applications. Industries can benefit from flexibility in installation and maintenance, as these pumps can often be moved or repositioned with ease.

small centrifugal slurry pump

Energy efficiency is another critical aspect of small centrifugal slurry pumps. Many modern models are designed with energy-saving features that reduce power consumption while maintaining performance. This is particularly important in an era where companies are increasingly focused on sustainable practices and minimizing their carbon footprints. By investing in energy-efficient pumping solutions, industries not only save on operational costs but also contribute to environmentally friendly practices.

Furthermore, advancements in pump technology have led to the development of smart slurry pumps equipped with monitoring systems. These systems can track performance metrics in real time, providing valuable data that helps operators optimize processes and predict maintenance needs. By embracing such technologies, businesses can significantly improve operational efficiency and reduce the risk of unexpected failures.

In conclusion, small centrifugal slurry pumps are indispensable tools across various industries that require the transfer of slurry mixtures. Their durability, compact design, energy efficiency, and integration of modern technology make them a key investment for any operation dealing with challenging materials. As industry demands continue to evolve, these pumps will remain vital in ensuring efficient and sustainable operations.

-

High-Performance Chemical Pumps for Sale – Industrial & Injection Solutions

NewsJul.28,2025

-

Large Industrial Sludge Slurry Pump Mining Wear-resistant Solutions

NewsJul.28,2025

-

High-Performance Septic Tank Pumps for Reliable Wastewater Management

NewsJul.26,2025

-

High Efficiency Horizontal Split Case Pump for Industrial Use

NewsJul.25,2025

-

Flue Gas Desulfurization Pump for Efficient Chemical Processing

NewsJul.24,2025

-

High-Efficiency Axial Flow Pump for Water Transfer & Irrigation

NewsJul.23,2025