TEL:

+86 13120555503

Uzbek

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Iyun . 13, 2024 11:05 Back to list

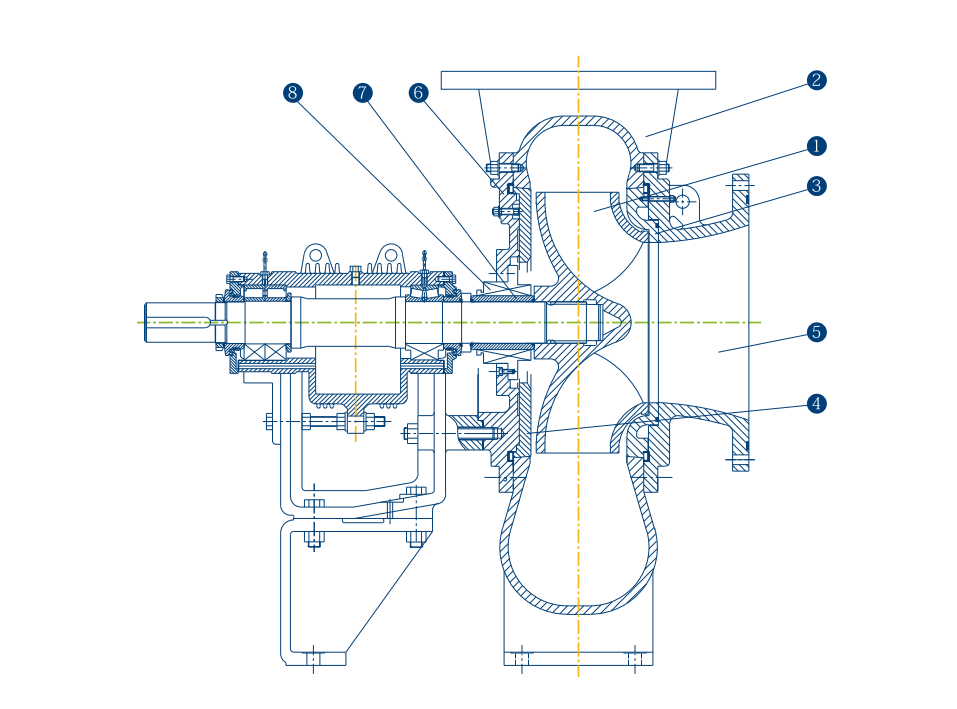

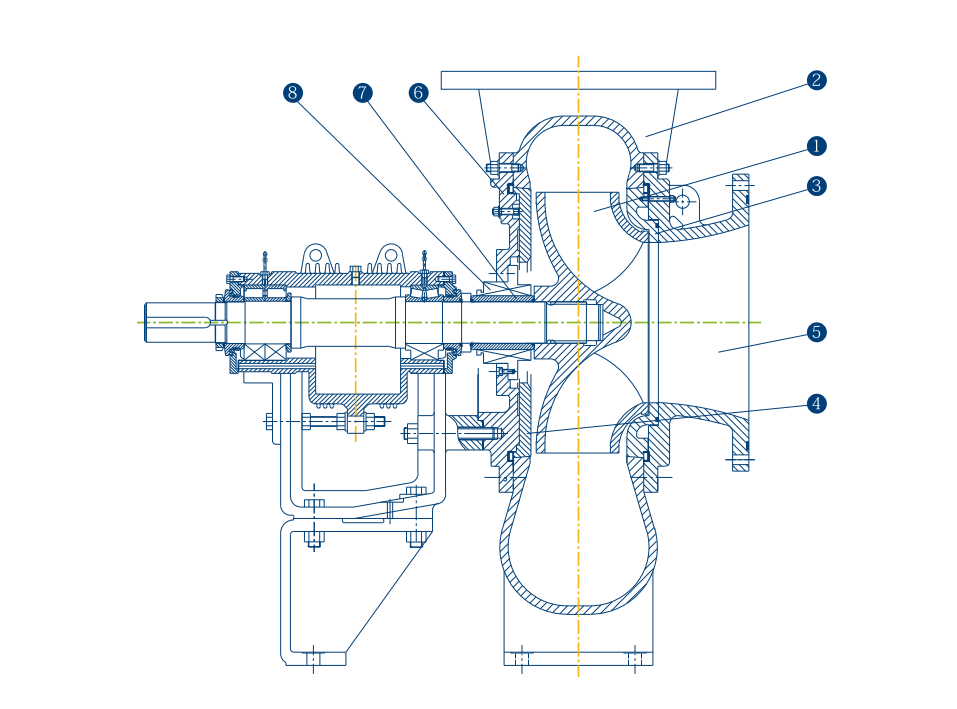

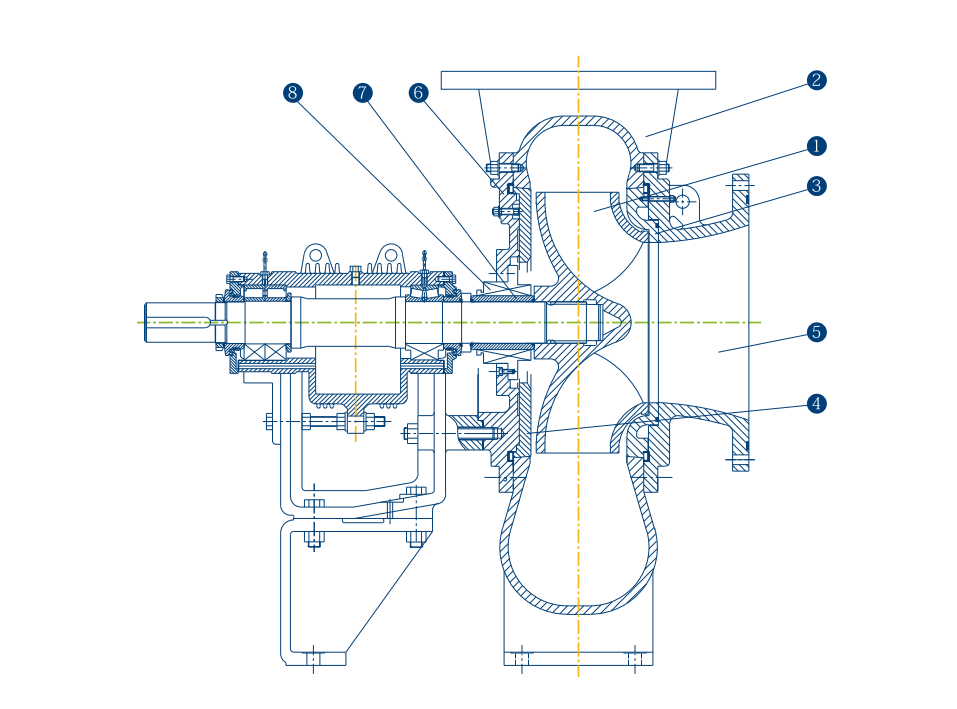

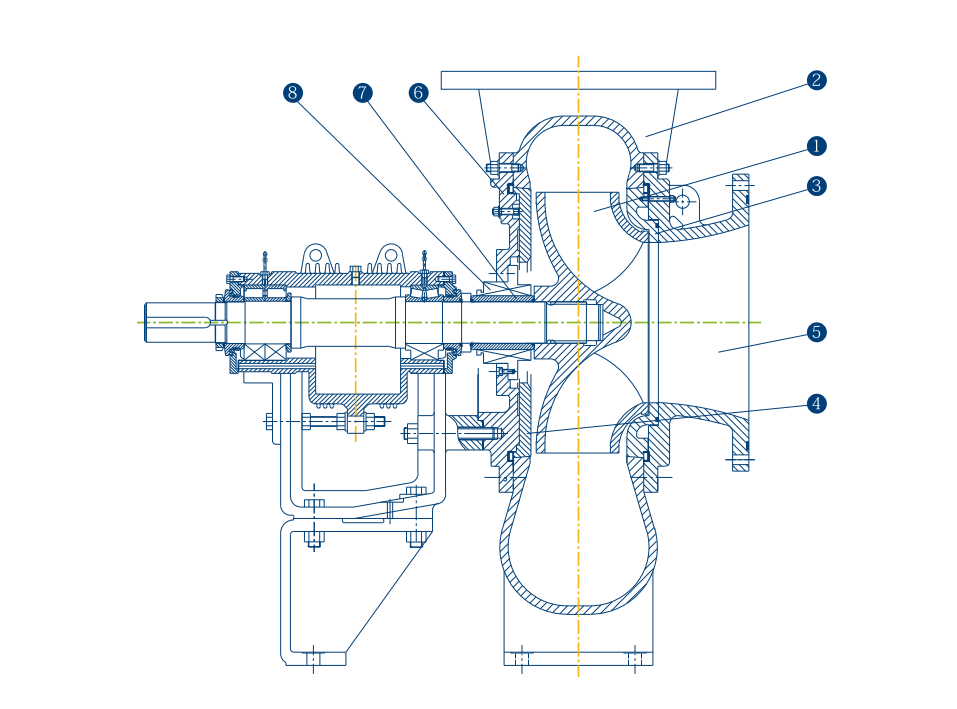

Slurry pump operates by moving solid-laden fluid efficiently.

Understanding the Working Principle of a Slurry Pump

A slurry pump is an essential piece of equipment in various industries, particularly those dealing with the transportation of solid-laden fluids, such as mining, construction, and wastewater treatment. The term slurry refers to a mixture of liquids and suspended solids, which can range from fine particles to large chunks. The working principle of a slurry pump is a complex interplay of mechanical force, hydraulic dynamics, and material engineering.

At its core, a slurry pump operates on the centrifugal principle, similar to a standard liquid pump. It consists of an impeller, a casing, suction and discharge ports, and a motor that drives the impeller. The impeller, located within the casing, is the primary working component that imparts kinetic energy to the slurry, converting the mechanical energy from the motor into fluid motion.

When the motor starts, the impeller rotates at high speed, creating a low-pressure area at the center, or suction end, of the pump. This draws the slurry into the pump through the suction port. As the slurry moves radially outward due to centrifugal force, it gains velocity and pressure. The impeller's vanes push the slurry towards the discharge port, which is typically positioned tangential to the impeller. The increase in pressure enables the slurry to flow against gravity or through pipelines to its destination.

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry slurry pump working principle. This requires robust construction materials, such as heavy-duty metals or high-chrome alloys, to withstand the wear and tear caused by the suspended solids. Additionally, the design of the impeller and casing often incorporates features like wider channels and thicker vanes to accommodate the larger particle size and minimize blockages.

Slurry pumps can be classified into two main categories centrifugal and positive displacement. Centrifugal pumps, as described above, rely on the spinning impeller to create a centrifugal force for fluid movement. Positive displacement pumps, on the other hand, use mechanisms like gears or pistons to move the slurry in a more direct, non-continuous manner. Each type has its advantages and is suited for different applications depending on factors like slurry consistency, required flow rate, and head pressure.

In conclusion, the working principle of a slurry pump lies in its ability to efficiently transfer and elevate solid-laden fluids using the centrifugal force generated by a rapidly rotating impeller. Its design and construction are tailored to withstand the harsh conditions of handling abrasive slurries, making it an indispensable tool in many industrial processes. Understanding this principle is crucial for optimal operation, maintenance, and selection of slurry pumps for specific tasks.

slurry pump working principle. This requires robust construction materials, such as heavy-duty metals or high-chrome alloys, to withstand the wear and tear caused by the suspended solids. Additionally, the design of the impeller and casing often incorporates features like wider channels and thicker vanes to accommodate the larger particle size and minimize blockages.

Slurry pumps can be classified into two main categories centrifugal and positive displacement. Centrifugal pumps, as described above, rely on the spinning impeller to create a centrifugal force for fluid movement. Positive displacement pumps, on the other hand, use mechanisms like gears or pistons to move the slurry in a more direct, non-continuous manner. Each type has its advantages and is suited for different applications depending on factors like slurry consistency, required flow rate, and head pressure.

In conclusion, the working principle of a slurry pump lies in its ability to efficiently transfer and elevate solid-laden fluids using the centrifugal force generated by a rapidly rotating impeller. Its design and construction are tailored to withstand the harsh conditions of handling abrasive slurries, making it an indispensable tool in many industrial processes. Understanding this principle is crucial for optimal operation, maintenance, and selection of slurry pumps for specific tasks.

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry

However, unlike clear liquid pumps, slurry pumps need to handle the abrasive nature of the slurry slurry pump working principle. This requires robust construction materials, such as heavy-duty metals or high-chrome alloys, to withstand the wear and tear caused by the suspended solids. Additionally, the design of the impeller and casing often incorporates features like wider channels and thicker vanes to accommodate the larger particle size and minimize blockages.

Slurry pumps can be classified into two main categories centrifugal and positive displacement. Centrifugal pumps, as described above, rely on the spinning impeller to create a centrifugal force for fluid movement. Positive displacement pumps, on the other hand, use mechanisms like gears or pistons to move the slurry in a more direct, non-continuous manner. Each type has its advantages and is suited for different applications depending on factors like slurry consistency, required flow rate, and head pressure.

In conclusion, the working principle of a slurry pump lies in its ability to efficiently transfer and elevate solid-laden fluids using the centrifugal force generated by a rapidly rotating impeller. Its design and construction are tailored to withstand the harsh conditions of handling abrasive slurries, making it an indispensable tool in many industrial processes. Understanding this principle is crucial for optimal operation, maintenance, and selection of slurry pumps for specific tasks.

slurry pump working principle. This requires robust construction materials, such as heavy-duty metals or high-chrome alloys, to withstand the wear and tear caused by the suspended solids. Additionally, the design of the impeller and casing often incorporates features like wider channels and thicker vanes to accommodate the larger particle size and minimize blockages.

Slurry pumps can be classified into two main categories centrifugal and positive displacement. Centrifugal pumps, as described above, rely on the spinning impeller to create a centrifugal force for fluid movement. Positive displacement pumps, on the other hand, use mechanisms like gears or pistons to move the slurry in a more direct, non-continuous manner. Each type has its advantages and is suited for different applications depending on factors like slurry consistency, required flow rate, and head pressure.

In conclusion, the working principle of a slurry pump lies in its ability to efficiently transfer and elevate solid-laden fluids using the centrifugal force generated by a rapidly rotating impeller. Its design and construction are tailored to withstand the harsh conditions of handling abrasive slurries, making it an indispensable tool in many industrial processes. Understanding this principle is crucial for optimal operation, maintenance, and selection of slurry pumps for specific tasks. Share

Next:

Latest news

-

Custom Drilling Mud and Slurry Pump Supplier - High Efficiency, Tailored Solutions

NewsJun.10,2025

-

Supply Vertical Submersible Sewage Pump High-Efficiency WQ/QW Pumps Supplier

NewsJun.10,2025

-

Premium Sewage Ejection System & Pumps Efficient Waste Removal

NewsJun.09,2025

-

Premium Wholesale Slurry Pump Impellers Durable & Efficient Slurry Handling

NewsJun.09,2025

-

Top Sewage Pump Companies Durable Industrial Solutions for Efficiency

NewsJun.09,2025

-

Heavy Duty Slurry Pumps - OEM High Performance & Bulk Wholesale

NewsJun.09,2025