Tajik

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dec . 30, 2024 07:31 Back to list

kirloskar submersible slurry pump

Kirloskar Submersible Slurry Pumps An Overview

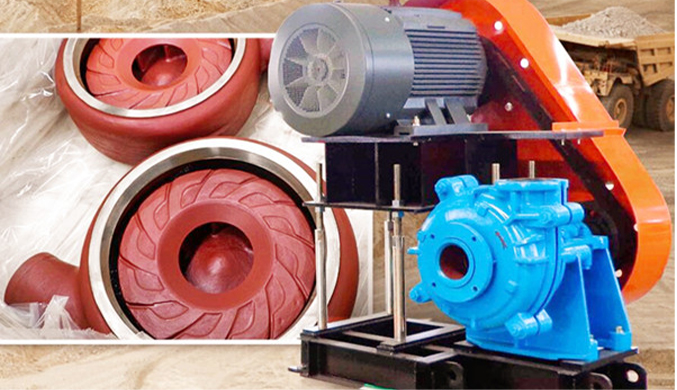

In the realm of industrial pumps, Kirloskar submersible slurry pumps have emerged as a vital solution for the transportation and handling of abrasive and viscous materials. Known for their robust construction and high efficiency, these pumps are essential in various sectors including mining, construction, and wastewater management. This article delves into the technical features, advantages, applications, and maintenance aspects of Kirloskar submersible slurry pumps, providing a comprehensive overview for potential users and industry professionals.

Technical Features

Kirloskar submersible slurry pumps are designed to operate under challenging conditions, often submerged in the fluid being pumped. Made of high-quality materials, these pumps are typically made with a combination of cast iron and stainless steel, ensuring durability and resistance to wear from abrasive materials. The impellers are robustly designed to handle solids of various sizes, making them particularly suitable for slurry applications.

The motor used in these pumps is often water-cooled and designed to provide submersible performance. Additionally, these pumps are equipped with advanced mechanical seals that enhance their reliability and reduce the risk of leakage. Many models feature variable speed drives, allowing operators to adjust flow rates according to specific requirements.

Advantages

One of the primary advantages of Kirloskar submersible slurry pumps is their ability to handle solids effectively while maintaining a consistent flow rate. The submersible design minimizes the need for priming, which is often required in above-ground pumps, thereby reducing downtime and enhancing operational efficiency. Moreover, being submerged reduces the risk of cavitation and minimizes air entrapment, further ensuring optimal performance.

Another significant benefit is their energy efficiency. With advancements in pump design and technology, these pumps consume less energy compared to traditional slurry handling methods. This not only contributes to lower operational costs but also aligns with the increasing global emphasis on sustainable practices.

kirloskar submersible slurry pump

Applications

Kirloskar submersible slurry pumps are versatile and find applications across a range of industries. In mining operations, they are commonly used to transport tailings, sludge, and other abrasive materials from pits or processing plants to retention areas or treatment facilities. Their ability to handle high solid concentrations makes them ideal for dredging operations as well.

In construction, these pumps are used for dewatering purposes, removing excess water and slurry from excavation sites. They ensure that construction projects proceed without delays caused by water accumulation. Additionally, in wastewater management, these pumps play a crucial role in transporting sludge from sewage treatment plants to various processing stages.

Maintenance and Care

Despite their robust design, regular maintenance is imperative for the optimal performance of Kirloskar submersible slurry pumps. Operators should conduct routine inspections to check for wear and tear on components like impellers and seals, which are critical for maintaining efficiency. It is also essential to monitor motor performance and check electrical connections, ensuring that the pump runs smoothly.

Furthermore, it is advisable to clean the pump periodically to prevent sludge buildup, which can hinder performance. Operators should follow the manufacturer's guidelines for lubrication and oil changes, as these practices extend the pump's life and ensure reliable operation.

Conclusion

Kirloskar submersible slurry pumps represent a significant advancement in pumping technology, offering durable solutions for industrial applications that involve abrasive and viscous materials. Their efficient performance, robust construction, and versatility make them indispensable in sectors such as mining, construction, and wastewater management. By investing in these pumps, industries can achieve better productivity while minimizing operational costs and environmental impact. The combination of reliability and innovation inherent in Kirloskar products ensures that users can tackle tough pumping challenges with confidence, paving the way for enhanced operational efficiency and sustainability in various projects.

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025