Swahili

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Desemba . 17, 2024 08:34 Back to list

axial vs mixed flow pump

Comparison of Axial Flow and Mixed Flow Pumps

Pumps are essential devices in various industries, capable of transferring fluids from one location to another. Among the various types of pumps available, axial flow and mixed flow pumps are notable for their specific operational mechanisms and applications. Understanding the differences and similarities between these two types enhances our ability to choose the right pump for specific applications.

Axial Flow Pumps

Axial flow pumps operate by moving fluids along the axis of the pump. The fluid enters the pump inlet and is directed straight through the impeller, which converts the mechanical energy from the motor into kinetic energy of the fluid. The design typically consists of a propeller-like impeller with blades that push the fluid parallel to the shaft. These pumps are most effective for applications requiring high flow rates and relatively low lift, making them ideal for drainage, irrigation, and some industrial processes.

One of the primary advantages of axial flow pumps is their efficiency when dealing with large volumes of fluid. They can operate at low power consumption levels, making them cost-effective for large-scale operations. However, they are not suitable for high-pressure applications due to their design limitations, which restrict their ability to generate the head necessary to lift fluids to significant heights.

Mixed Flow Pumps

Mixed flow pumps embody characteristics of both axial flow and centrifugal pumps. In these pumps, the fluid is not only moved along the axis as in axial flow pumps but also experiences a radial component of flow. This design allows them to balance the features of both types, enabling them to handle moderate flow rates and higher pressures effectively.

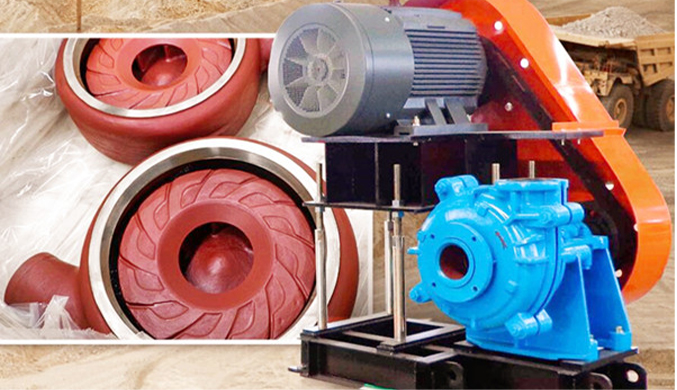

axial vs mixed flow pump

Mixed flow pumps feature an impeller design that combines blades positioned at an angle, allowing fluid to be pushed both axially and radially. This unique design allows mixed flow pumps to deliver a higher head than axial flow pumps while still maintaining a considerable flow rate. They are commonly used in applications such as water supply facilities, wastewater treatment, and in various industrial processes where versatility in flow rate and pressure is necessary.

Advantages and Disadvantages

When comparing axial flow and mixed flow pumps, several factors should be considered. Axial flow pumps are generally simpler in design and easier to maintain. They are also more efficient at higher flow rates, making them the preferred choice for applications that prioritize fluid volume over pressure. However, their limitation in generating head can be a significant drawback when dealing with high discharge pressures.

In contrast, mixed flow pumps provide greater versatility. They are capable of functioning effectively across a wider range of applications, striking a balance between flow rate and head. However, this versatility often comes at a higher initial cost and may require more complex maintenance due to their dual flow dynamics.

Conclusion

In summary, both axial flow and mixed flow pumps serve crucial roles in fluid transfer across many industries. Axial flow pumps are ideal for high-flow, low-head scenarios, whereas mixed flow pumps offer flexibility and efficiency in systems requiring a balance of flow and pressure. The choice between the two ultimately hinges on the specific requirements of the application, such as the desired flow rate, head pressure, and overall system design. Understanding these differences enables engineers and technicians to make informed decisions, ultimately enhancing operational efficiency and cost-effectiveness in fluid handling processes.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025