Swedish

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

nov . 07, 2024 14:32 Back to list

Leading Manufacturers of Submersible Slurry Pumps for Various Industrial Applications

The Role of Submersible Slurry Pump Manufacturers in Industrial Applications

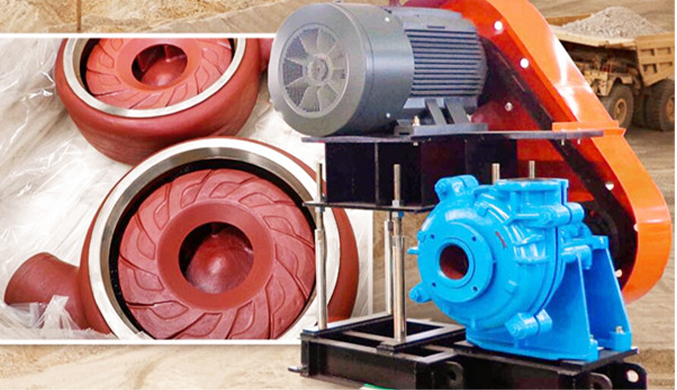

Submersible slurry pumps are essential components in various industrial applications where the transport of abrasive and viscous materials is required. These specialized pumps are designed to handle mixtures of liquid and solid particles, making them invaluable in industries such as mining, construction, and wastewater management. The role of submersible slurry pump manufacturers has become increasingly significant as they develop innovative solutions that meet the growing demands of these sectors.

Understanding Submersible Slurry Pumps

Submersible slurry pumps are designed to operate underwater, enabling them to deliver slurry mixtures while submerged in the fluid. Unlike traditional pumps that are located above the liquid level, submersible pumps are sealed and can work efficiently in challenging environments. They are particularly adept at handling materials like sand, gravel, sludge, and other heavy solids. The main components of these pumps include a motor, pump casing, and impeller, all of which are engineered to withstand the wear and tear caused by abrasive particles.

Key Benefits of Submersible Slurry Pumps

1. High Efficiency These pumps can transfer large volumes of slurry more efficiently than standard pumps, reducing energy consumption and operational costs.

2. Versatility Submersible slurry pumps can be used in various applications, including dredging, dewatering, mining operations, and even in the management of wastewater. Their adaptability makes them a valuable asset in industrial settings.

3. Reduced Maintenance Needs As they are designed to handle abrasive materials, submersible slurry pumps often require less frequent maintenance compared to other types of pumps. This reliability translates to less downtime and increased productivity.

4. Space-Saving Design The submersible nature of these pumps means they can be positioned directly at the source of the slurry, saving valuable space and reducing the need for extensive piping systems.

submersible slurry pump manufacturers

The Role of Manufacturers

Submersible slurry pump manufacturers play a crucial role in the development and innovation of pump technology. Their responsibilities include designing pumps that not only meet industry standards but also address specific client needs. This involves extensive research and development to create robust pumps that can handle extreme conditions, including high-pressure environments and corrosive elements. Moreover, manufacturers must ensure their products comply with safety regulations and industry guidelines.

1. Innovation and Technology Leading manufacturers invest in cutting-edge technology to improve the performance and durability of submersible slurry pumps. This includes advancements in materials, like employing high-chrome alloys to resist wear and tear, and the development of more efficient motor designs that enhance overall energy efficiency.

2. Customization Not all applications are the same; hence, manufacturers often provide customized solutions tailored to specific operational requirements. This can range from designing pumps with specific flow rates to modifying impeller designs for unique slurry compositions.

3. Customer Support A reliable manufacturer not only sells pumps but also offers comprehensive support, including installation guidance, maintenance services, and troubleshooting assistance. This support is critical for ensuring that pumps operate at peak efficiency.

4. Global Reach Many submersible slurry pump manufacturers operate on a global scale, providing equipment to various industries around the world. This international presence allows them to understand diverse market needs and adapt their offerings accordingly.

Conclusion

In conclusion, submersible slurry pump manufacturers are integral to the success of operations that involve the handling of abrasive materials. Their commitment to innovation, customization, and customer support ensures that industries can efficiently manage slurry with minimal downtime and at reduced costs. As technology evolves and the demands of the industry continue to grow, the role of these manufacturers will remain vital in shaping the future of industrial pumping solutions. As businesses seek to optimize their operations, partnering with reputable submersible slurry pump manufacturers will undoubtedly play a key role in achieving their goals.

-

Reliable Non-Clog Sewage Pumps with GPT-4-Turbo Tech

NewsAug.04,2025

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025