TEL:

+86 13120555503

Somali

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Jun . 28, 2024 11:40 Back to list

3. Lime Slurry Injection Technology

Lime Slurry Pumping A Crucial Process in Environmental Protection

In the realm of environmental protection, lime slurry pumping holds a significant position. This process involves the transportation of a mixture of water and calcium hydroxide (lime) to neutralize acidic pollutants in various industrial processes. The efficiency and reliability of this process are crucial for achieving environmental compliance and maintaining ecological balance.

The primary function of lime slurry pumping is to neutralize acidic substances, such as sulfur dioxide and nitrogen oxides, which are commonly released into the atmosphere during industrial activities. These pollutants can have detrimental effects on the environment, including acid rain, soil erosion, and harm to aquatic life. By injecting lime slurry into these emissions, the pH level is increased, thereby neutralizing the harmful acids and reducing their impact on the environment.

The process of lime slurry pumping involves several key steps. Firstly, raw materials, such as limestone and water, are mixed in the appropriate proportions to create the lime slurry. This mixture is then transferred to a storage tank, where it is agitated to ensure proper mixing. Once the lime slurry is ready, it is pumped through pipelines to the point of injection, where it is injected into the flue gas stream.

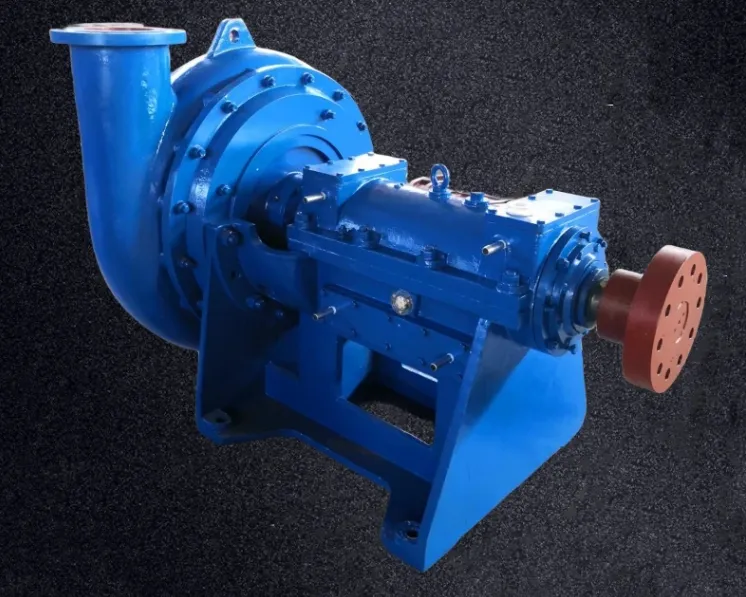

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture lime slurry pumping. Lime slurry has a high viscosity and can be prone to clogging if not properly handled. Therefore, pumps with high pressure capabilities and anti-clogging features are typically used for this application. These pumps are designed to handle abrasive and corrosive fluids, making them well-suited for handling lime slurry.

The effectiveness of lime slurry pumping can be significantly enhanced by optimizing the injection process. Factors such as injection rate, injection location, and temperature all play important roles in determining the neutralization efficiency. By carefully controlling these variables, it is possible to achieve optimal performance and maximize the benefits of lime slurry pumping.

In conclusion, lime slurry pumping is a vital process in the field of environmental protection. It plays a crucial role in neutralizing acidic pollutants and protecting the environment from their harmful effects. By selecting the right pumps and optimizing the injection process, it is possible to achieve efficient and reliable performance, contributing to a cleaner and more sustainable future.

lime slurry pumping. Lime slurry has a high viscosity and can be prone to clogging if not properly handled. Therefore, pumps with high pressure capabilities and anti-clogging features are typically used for this application. These pumps are designed to handle abrasive and corrosive fluids, making them well-suited for handling lime slurry.

The effectiveness of lime slurry pumping can be significantly enhanced by optimizing the injection process. Factors such as injection rate, injection location, and temperature all play important roles in determining the neutralization efficiency. By carefully controlling these variables, it is possible to achieve optimal performance and maximize the benefits of lime slurry pumping.

In conclusion, lime slurry pumping is a vital process in the field of environmental protection. It plays a crucial role in neutralizing acidic pollutants and protecting the environment from their harmful effects. By selecting the right pumps and optimizing the injection process, it is possible to achieve efficient and reliable performance, contributing to a cleaner and more sustainable future.

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture

The choice of pump for lime slurry pumping is critical due to the unique properties of this mixture lime slurry pumping. Lime slurry has a high viscosity and can be prone to clogging if not properly handled. Therefore, pumps with high pressure capabilities and anti-clogging features are typically used for this application. These pumps are designed to handle abrasive and corrosive fluids, making them well-suited for handling lime slurry.

The effectiveness of lime slurry pumping can be significantly enhanced by optimizing the injection process. Factors such as injection rate, injection location, and temperature all play important roles in determining the neutralization efficiency. By carefully controlling these variables, it is possible to achieve optimal performance and maximize the benefits of lime slurry pumping.

In conclusion, lime slurry pumping is a vital process in the field of environmental protection. It plays a crucial role in neutralizing acidic pollutants and protecting the environment from their harmful effects. By selecting the right pumps and optimizing the injection process, it is possible to achieve efficient and reliable performance, contributing to a cleaner and more sustainable future.

lime slurry pumping. Lime slurry has a high viscosity and can be prone to clogging if not properly handled. Therefore, pumps with high pressure capabilities and anti-clogging features are typically used for this application. These pumps are designed to handle abrasive and corrosive fluids, making them well-suited for handling lime slurry.

The effectiveness of lime slurry pumping can be significantly enhanced by optimizing the injection process. Factors such as injection rate, injection location, and temperature all play important roles in determining the neutralization efficiency. By carefully controlling these variables, it is possible to achieve optimal performance and maximize the benefits of lime slurry pumping.

In conclusion, lime slurry pumping is a vital process in the field of environmental protection. It plays a crucial role in neutralizing acidic pollutants and protecting the environment from their harmful effects. By selecting the right pumps and optimizing the injection process, it is possible to achieve efficient and reliable performance, contributing to a cleaner and more sustainable future. Share

Latest news

-

Durable & Efficient Submersible Mixed Flow Propeller Pumps Quotes

NewsApr.29,2025

-

BPA-Free Sand Gravel Pump for Aquariums & Industrial Use Terapump

NewsApr.29,2025

-

High-Efficiency Big Capacity Double Suction Pumps Bulk Supply

NewsApr.28,2025

-

High-Performance Vapor Honing Slurry Pumps Durable & Efficient Solutions

NewsApr.28,2025

-

OEM Slurry Pump Engineering Factory Custom Solutions & Durable Pumps

NewsApr.28,2025

-

1HP Sewage Submersible Pump Durable Vertical & WQ/QW Models Supplier

NewsApr.28,2025