Samoan

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dec . 19, 2024 01:52 Back to list

slurry pumps manufacturers

Understanding Slurry Pumps A Look at Manufacturers and their Innovations

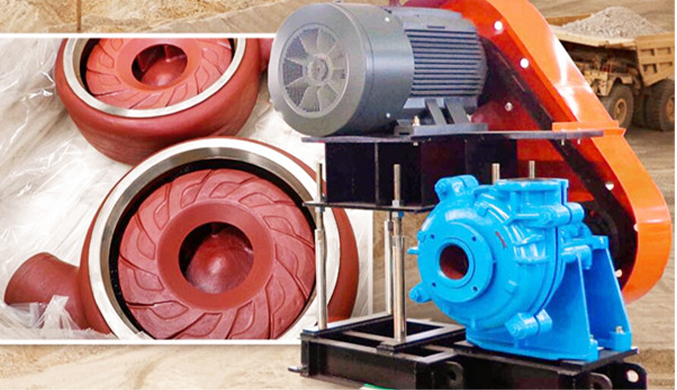

Slurry pumps play a crucial role in various industries by transporting mixtures of liquid and solid materials, commonly known as slurries. These pumps are vital in sectors such as mining, construction, and wastewater treatment, where efficient and reliable movement of abrasive, corrosive, or thick materials is necessary. With their increasing demand, numerous manufacturers have emerged, each offering unique solutions and innovations to meet the needs of diverse applications. This article explores the world of slurry pump manufacturers, highlighting their contributions and advancements in pump technology.

The Role of Slurry Pumps

Slurry pumps are designed to handle a range of materials, including sand, coal, ores, and slurry mixtures found in mining operations, as well as municipal and industrial wastewater. They differ from standard pumps due to their ability to manage abrasive and often high-density fluids. The successful operation of slurry pumps depends on their design features, material selection, and the specific requirements of the application they are intended for. Reliability, durability, and maintenance ease are the hallmarks of high-quality slurry pump solutions.

Leading Manufacturers in the Industry

Several manufacturers have established themselves as industry leaders in the production of slurry pumps. Among them, companies like Weir Group, Schurco Slurry, and Metso Outotec stand out for their innovative designs and superior product lines.

1. Weir Group The Weir Group is renowned for its extensive range of slurry pumps designed for various applications, particularly in the mining and minerals processing sectors. Their brand, Warman, is synonymous with high performance, durability, and advanced technology. Weir’s investment in research and development has led to innovative materials that enhance pump life and efficiency, making them a preferred choice for many large-scale operations.

slurry pumps manufacturers

2. Schurco Slurry Schurco Slurry specializes in manufacturing and designing slurry pumps for a variety of industries, focusing on providing tailored solutions for specific customer needs. They offer replacement parts for existing slurry pumps, which promotes a sustainable approach by extending the life cycle of equipment. Schurco Slurry emphasizes customer service and engineering support, assisting clients in selecting the right solutions for their operations.

3. Metso Outotec Metso Outotec is another prominent player, making strides in the development of eco-friendly and energy-efficient slurry pumps. Their comprehensive range of products caters to mining, aggregates, and industrial applications, emphasizing modular designs that can be customized to fit unique operational requirements. Metso Outotec also integrates digital technologies into their innovations, enabling customers to monitor and optimize pump performance remotely.

Innovations and Trends

The slurry pump industry is witnessing several trends driven by advancements in technology and increasing environmental regulations. One significant trend is the incorporation of digital monitoring systems, allowing operators to gather real-time data on pump performance. This data aids in predictive maintenance, minimizing downtime and maximizing efficiency.

Another important innovation is the development of pumps with enhanced wear resistance. Manufacturers are focusing on advanced materials and coatings to reduce the impact of abrasive solids on pump components, extending pump life and reducing maintenance costs. Additionally, efforts are being made to improve energy efficiency, aligning with global sustainability goals.

Conclusion

As the demand for effective slurry transportation continues to rise across industries, manufacturers are at the forefront of innovation, enhancing the reliability and efficiency of slurry pumps. Companies like Weir Group, Schurco Slurry, and Metso Outotec showcase the importance of research and development in creating pumps that not only meet customer needs but also contribute to sustainable industrial practices. As advancements in technology pave the way for smarter, more efficient slurry pumping solutions, end-users can look forward to enhanced performance and reduced operating costs. The future of slurry pumps is not just about moving materials; it’s about moving towards a more efficient and sustainable industrial landscape.

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025