Sindhi

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 02, 2024 10:38 Back to list

self priming slurry pump

Self-Priming Slurry Pump An Overview

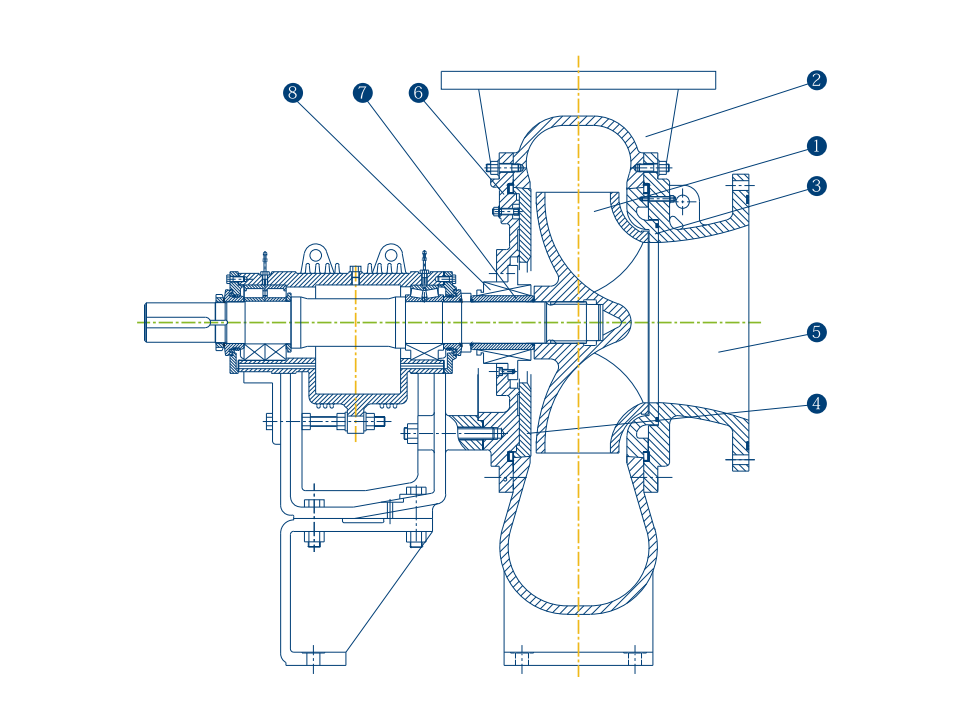

Self-priming slurry pumps play a crucial role in various industrial applications where the movement of abrasive and viscous slurry is required. They are designed to handle mixtures containing solid particles, making them an essential component in sectors such as mining, construction, and wastewater treatment.

The primary advantage of a self-priming slurry pump lies in its ability to create a vacuum that allows it to draw liquid from a lower level without the need for additional priming equipment. This self-priming ability significantly reduces operational complexity and ensures that the pump is ready for use even if it has been idle for a while.

How It Works

Self-Priming Slurry Pump An Overview

The self-priming feature means that these pumps can be installed above the liquid source, which can be particularly advantageous in situations where the slurry needs to be transferred from deep pits or tanks. Additionally, the pumps are engineered to handle both high solid content and varying degrees of viscosity, making them versatile for numerous applications.

self priming slurry pump

Applications

Self-priming slurry pumps are commonly employed in the mining industry for transporting mixtures of water and ore, especially in areas with fluctuating water levels. They are invaluable in dredging operations, where the movement of sand and silt is necessary. In wastewater treatment plants, these pumps facilitate the transfer of sludge, ensuring smooth operation of the treatment processes.

Furthermore, in construction projects, self-priming slurry pumps are vital for dewatering sites, managing water and mud mixtures effectively. Their robust construction allows them to withstand abrasive materials without significant wear, prolonging the lifespan of the pump.

Conclusion

In summary, self-priming slurry pumps are vital in managing challenging fluids containing solid particles across various industries. Their ability to operate without external priming, combined with their durability and efficiency, makes them a preferred choice in applications requiring reliable fluid transfer. As technology evolves, these pumps continue to adapt, offering enhanced performance and reliability, thereby meeting the demands of modern industrial processes.

-

High-Efficiency Submersible Effluent Pump for Sewage & Wastewater Solutions

NewsJul.08,2025

-

High Quality CH Warman Slurry Pump Factory - Leading Horizontal Slurry Pump Supplier

NewsJul.08,2025

-

Hot Sale Chemical Circulating Pump – Efficient & Durable Slurry Circulating Pump Solutions

NewsJul.08,2025

-

High-Efficiency Submersible Dredge Pump for Sand & Gravel Durable Dredge Slurry Pumps Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Impeller Supplier – High-Quality & Efficient Pump Parts for Enhanced Performance

NewsJul.07,2025

-

High-Efficiency Water Submersible Pumps Reliable Water Pump for Potable Water Supply

NewsJul.06,2025