TEL:

+86 13120555503

Russian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Июл . 02, 2024 03:00 Back to list

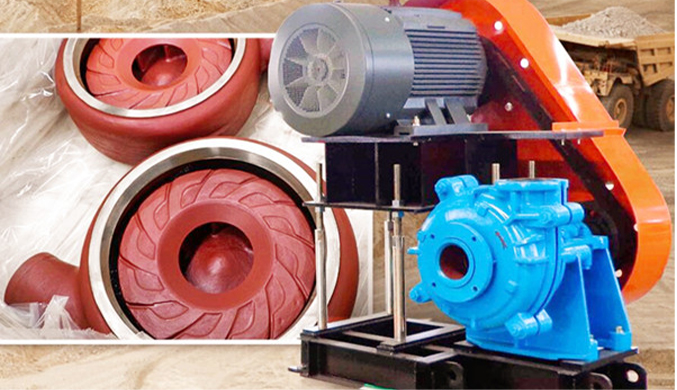

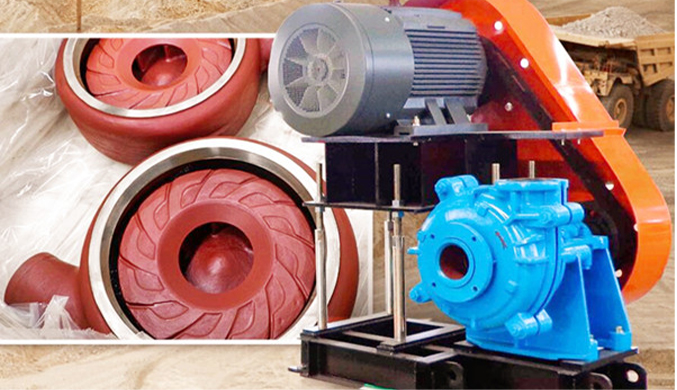

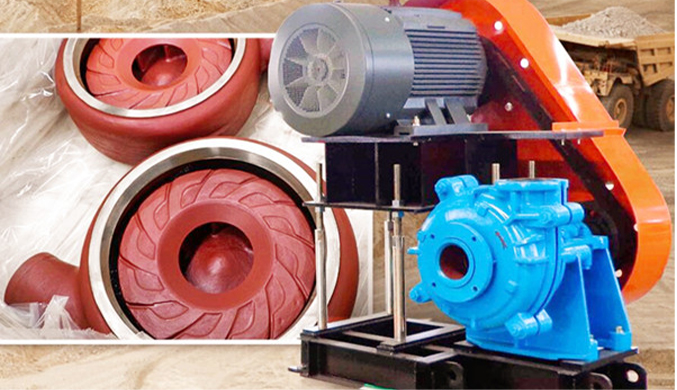

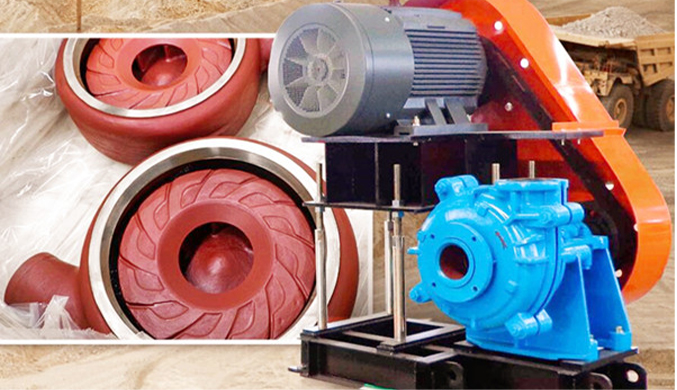

Corrosion-Resistant Water Pump for Chemical Applications

The Importance of Chemical Resistant Water Pumps in Industrial Applications

In an era where chemical processing and industrial operations are integral to our daily lives, the role of a chemical resistant water pump cannot be overstated. These specialized pumps are designed to handle fluids that contain harsh chemicals, acids, alkalis, and other corrosive substances, ensuring efficient and safe transportation without damage to the equipment. This 600-word article delves into the significance, features, and applications of chemical resistant water pumps.

A chemical resistant water pump is essentially a mechanical device that transfers liquids, particularly those with high chemical compositions, from one location to another. The key feature that sets it apart from conventional pumps is its construction material. Typically made from materials like polypropylene, PVDF, or stainless steel, these pumps can withstand the aggressive nature of chemicals, preventing corrosion and prolonging the lifespan of the equipment.

The importance of chemical resistant water pumps lies in their ability to handle a wide range of chemical processes. In industries such as pharmaceuticals, chemical manufacturing, wastewater treatment, and oil and gas, these pumps play a critical role. They ensure the safe handling and transfer of hazardous chemicals, minimizing the risk of leaks, spills, and environmental contamination. Moreover, their durability and resistance to chemical erosion reduce maintenance costs and downtime, thereby improving overall operational efficiency.

One of the primary advantages of these pumps is their versatility. Depending on the specific application and chemical properties, different types of chemical resistant pumps are available. Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids

Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids chemical resistant water pump. Magnetic drive pumps, on the other hand, offer a leak-proof design, making them perfect for handling toxic or volatile chemicals.

Another crucial aspect is the pump's system. A robust seal ensures that no chemical leaks out, protecting both personnel and the surrounding environment. Mechanical seals, packed glands, or magnetic couplings are commonly used in chemical resistant water pumps to achieve this.

In addition to their functional benefits, chemical resistant water pumps also contribute to sustainability efforts. By efficiently transporting and containing chemicals, they minimize waste and potential environmental harm. Furthermore, their durable construction often leads to a longer service life, reducing the need for frequent replacements and the associated carbon footprint.

In conclusion, chemical resistant water pumps are indispensable tools in industries that deal with corrosive substances. Their resilience, versatility, and safety features make them a reliable solution for challenging fluid handling tasks. As technology advances, we can expect further improvements in pump design, enhancing efficiency, and expanding the scope of applications for these vital pieces of machinery. Whether it's moving acids in a chemical plant or treating contaminated water, chemical resistant water pumps continue to play a pivotal role in ensuring smooth and safe industrial operations.

chemical resistant water pump. Magnetic drive pumps, on the other hand, offer a leak-proof design, making them perfect for handling toxic or volatile chemicals.

Another crucial aspect is the pump's system. A robust seal ensures that no chemical leaks out, protecting both personnel and the surrounding environment. Mechanical seals, packed glands, or magnetic couplings are commonly used in chemical resistant water pumps to achieve this.

In addition to their functional benefits, chemical resistant water pumps also contribute to sustainability efforts. By efficiently transporting and containing chemicals, they minimize waste and potential environmental harm. Furthermore, their durable construction often leads to a longer service life, reducing the need for frequent replacements and the associated carbon footprint.

In conclusion, chemical resistant water pumps are indispensable tools in industries that deal with corrosive substances. Their resilience, versatility, and safety features make them a reliable solution for challenging fluid handling tasks. As technology advances, we can expect further improvements in pump design, enhancing efficiency, and expanding the scope of applications for these vital pieces of machinery. Whether it's moving acids in a chemical plant or treating contaminated water, chemical resistant water pumps continue to play a pivotal role in ensuring smooth and safe industrial operations.

Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids

Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids Centrifugal pumps, for instance, are ideal for high flow rates and low-pressure applications, while diaphragm pumps excel in handling viscous or abrasive fluids chemical resistant water pump. Magnetic drive pumps, on the other hand, offer a leak-proof design, making them perfect for handling toxic or volatile chemicals.

Another crucial aspect is the pump's system. A robust seal ensures that no chemical leaks out, protecting both personnel and the surrounding environment. Mechanical seals, packed glands, or magnetic couplings are commonly used in chemical resistant water pumps to achieve this.

In addition to their functional benefits, chemical resistant water pumps also contribute to sustainability efforts. By efficiently transporting and containing chemicals, they minimize waste and potential environmental harm. Furthermore, their durable construction often leads to a longer service life, reducing the need for frequent replacements and the associated carbon footprint.

In conclusion, chemical resistant water pumps are indispensable tools in industries that deal with corrosive substances. Their resilience, versatility, and safety features make them a reliable solution for challenging fluid handling tasks. As technology advances, we can expect further improvements in pump design, enhancing efficiency, and expanding the scope of applications for these vital pieces of machinery. Whether it's moving acids in a chemical plant or treating contaminated water, chemical resistant water pumps continue to play a pivotal role in ensuring smooth and safe industrial operations.

chemical resistant water pump. Magnetic drive pumps, on the other hand, offer a leak-proof design, making them perfect for handling toxic or volatile chemicals.

Another crucial aspect is the pump's system. A robust seal ensures that no chemical leaks out, protecting both personnel and the surrounding environment. Mechanical seals, packed glands, or magnetic couplings are commonly used in chemical resistant water pumps to achieve this.

In addition to their functional benefits, chemical resistant water pumps also contribute to sustainability efforts. By efficiently transporting and containing chemicals, they minimize waste and potential environmental harm. Furthermore, their durable construction often leads to a longer service life, reducing the need for frequent replacements and the associated carbon footprint.

In conclusion, chemical resistant water pumps are indispensable tools in industries that deal with corrosive substances. Their resilience, versatility, and safety features make them a reliable solution for challenging fluid handling tasks. As technology advances, we can expect further improvements in pump design, enhancing efficiency, and expanding the scope of applications for these vital pieces of machinery. Whether it's moving acids in a chemical plant or treating contaminated water, chemical resistant water pumps continue to play a pivotal role in ensuring smooth and safe industrial operations. Share

Latest news

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025