TEL:

+86 13120555503

Romanian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

feb. . 05, 2025 03:34 Back to list

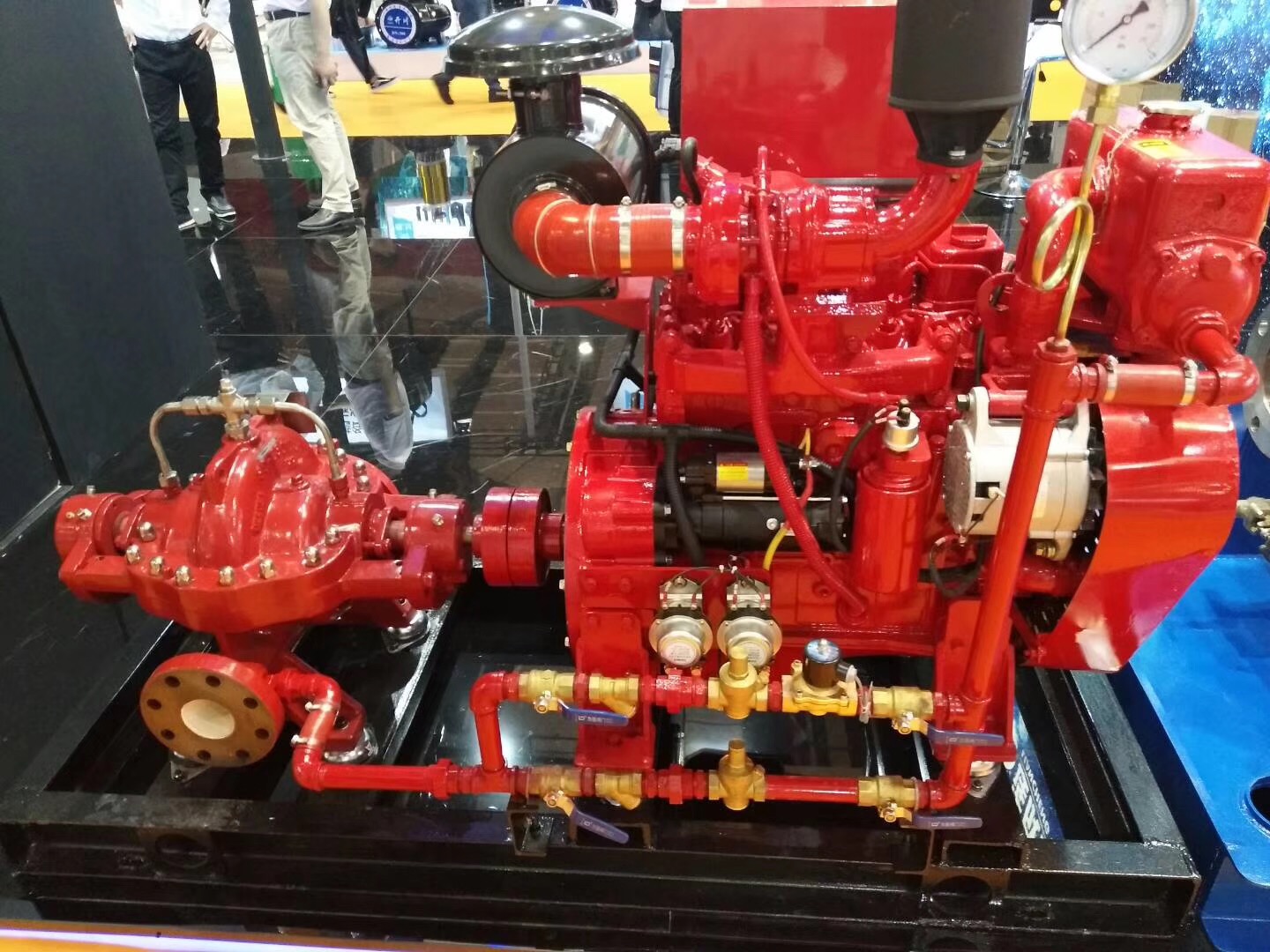

china vertical centrifugal slurry pump

Exploring the intricate world of vertical slurry sump pump rubber parts manufacturers unveils a symphony of engineering precision, material science, and specialized knowledge that can make a profound difference in industries dealing with abrasive materials. This article aims to provide a comprehensive understanding for those navigating this niche but vital market.

Authoritativeness in manufacturing is further reflected through industry recognition. Reputable manufacturers often partner with leading pump OEMs and have a significant presence in trade shows and industry conferences. They contribute to academic and practical dialogue by publishing case studies and whitepapers, thereby establishing themselves as thought leaders. Their contributions push industry standards forward and shape best practices. Trustworthiness is built through the consistent delivery of quality products and excellent customer service. Manufacturers in this space provide warranties and comprehensive after-sales support that reassure clients of the durability and performance of their products. Transparent communication and an openness to feedback strengthen customer relationships and foster a dependable reputation. Furthermore, compliance with environmental and safety regulations ensures that their operations do not compromise ecological or human health. Customers should look for a company that not only supplies parts but also collaborates closely to understand specific operational needs and constraints. They should offer consultation services and field support to optimize the installation and maintenance of rubber parts. This holistic approach underscores a manufacturer's dedication to customer success and positions them as a robust partner in achieving business goals. Choosing the right vertical slurry sump pump rubber parts manufacturer is a pivotal decision impacting the efficiency and productivity of any operation dealing with abrasive materials. A manufacturer’s experience, expertise, authoritativeness, and trustworthiness form the foundation of a fruitful partnership that drives operational excellence. As industries continue to evolve, the importance of these characteristics in rubber parts manufacturers will only grow, making them indispensable allies in navigating the challenges of handling abrasive slurries.

Authoritativeness in manufacturing is further reflected through industry recognition. Reputable manufacturers often partner with leading pump OEMs and have a significant presence in trade shows and industry conferences. They contribute to academic and practical dialogue by publishing case studies and whitepapers, thereby establishing themselves as thought leaders. Their contributions push industry standards forward and shape best practices. Trustworthiness is built through the consistent delivery of quality products and excellent customer service. Manufacturers in this space provide warranties and comprehensive after-sales support that reassure clients of the durability and performance of their products. Transparent communication and an openness to feedback strengthen customer relationships and foster a dependable reputation. Furthermore, compliance with environmental and safety regulations ensures that their operations do not compromise ecological or human health. Customers should look for a company that not only supplies parts but also collaborates closely to understand specific operational needs and constraints. They should offer consultation services and field support to optimize the installation and maintenance of rubber parts. This holistic approach underscores a manufacturer's dedication to customer success and positions them as a robust partner in achieving business goals. Choosing the right vertical slurry sump pump rubber parts manufacturer is a pivotal decision impacting the efficiency and productivity of any operation dealing with abrasive materials. A manufacturer’s experience, expertise, authoritativeness, and trustworthiness form the foundation of a fruitful partnership that drives operational excellence. As industries continue to evolve, the importance of these characteristics in rubber parts manufacturers will only grow, making them indispensable allies in navigating the challenges of handling abrasive slurries.

Share

Next:

Latest news

-

pipeline pump - Chi Yuan Pumps Co., LTD. | High Efficiency, Energy Saving

NewsAug.10,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Stable Performance

NewsAug.09,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps Co., LTD. | High Efficiency, Low Noise

NewsAug.09,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Efficiency, Durability

NewsAug.09,2025

-

Non Clog Sewage Pump: Submersible & High-Flow Solutions

NewsAug.09,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Compact Design

NewsAug.09,2025