Polish

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

lis . 06, 2024 17:31 Back to list

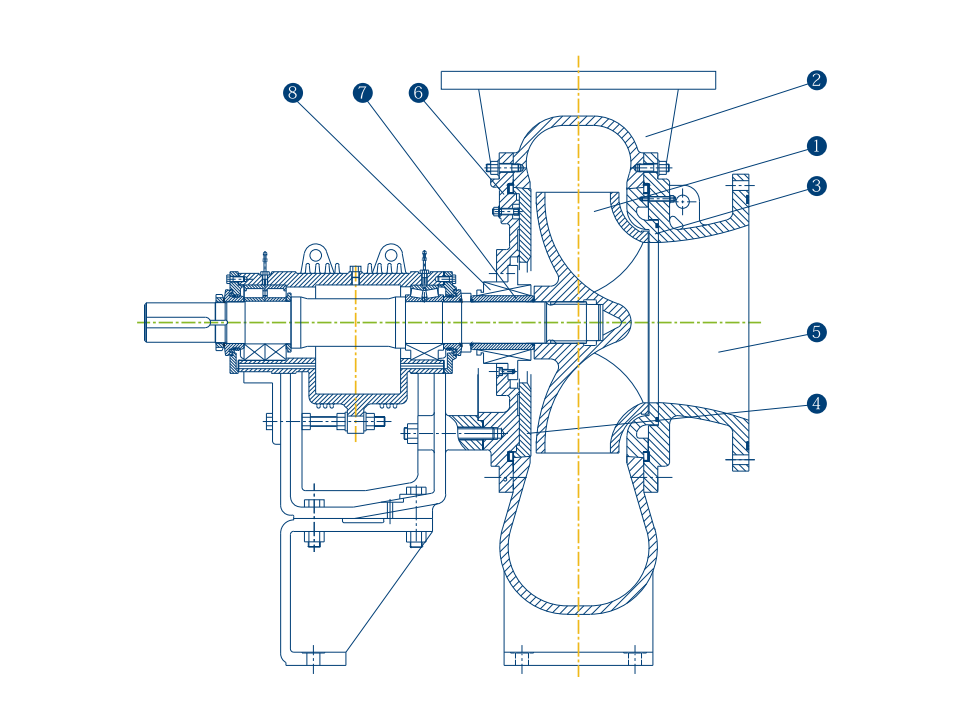

Design and Efficiency Analysis of Double Suction Volute Pumps for Enhanced Fluid Handling

Understanding Double Suction Volute Pumps A Comprehensive Overview

Double suction volute pumps are an essential component in many industrial and municipal applications, particularly in water management, irrigation, and various processes requiring the movement of fluids. These pumps are praised for their efficiency, reliability, and ability to handle large volumes of fluid with minimal energy consumption. In this article, we will delve into the working principle, design features, applications, advantages, and maintenance of double suction volute pumps.

Working Principle

The double suction volute pump operates on the principle of converting rotational kinetic energy, imparted by a rotating impeller, into hydraulic energy. As the impeller spins, it creates a low-pressure area at its center, allowing fluid to enter from both sides — hence the term double suction. The fluid flows through the impeller and is expelled into the volute chamber, designed in a spiral shape to convert the velocity of the fluid into pressure. This dual-suction feature allows for smoother operation and significantly reduces axial thrust, enhancing the pump's longevity and performance.

Design Features

1. Impeller Design The impeller is a crucial component, usually designed with two suction inlets. This dual inlet significantly reduces the radial forces acting on the pump, thus minimizing wear and extending equipment life.

2. Volute Chamber The volute chamber is expertly designed to efficiently manage fluid dynamics, providing smooth transitions for the fluid as it exits the impeller. Its spiral shape facilitates an even distribution of pressure, which is critical in maintaining efficiency.

3. Bearings and Shaft The shaft and bearing assembly in double suction volute pumps are designed for durability, absorbing the operational stresses while maintaining alignment and reducing the risk of mechanical failure.

4. Materials of Construction The materials used in manufacturing these pumps are often alloys or composites resistant to corrosion and wear, tailored to the specific needs of the application, whether it be chemical processing, wastewater management, or industrial fluid transfer.

Applications

Double suction volute pumps are versatile and are found in a wide range of applications

- Water Supply Systems These pumps are commonly used in municipal and industrial water supply systems due to their ability to move large quantities of water efficiently.

- Irrigation and Agriculture They play a vital role in irrigation systems, providing the necessary flow and pressure to sustain agricultural activities.

double suction volute pump

- Firefighting Systems With their impressive flow rates, these pumps are suitable for firefighting water supply systems, offering rapid response capabilities.

- Industrial Processes Industries such as power generation, chemical processing, and petrochemicals employ double suction volute pumps for various applications, including cooling water circulation and process fluid delivery

.Advantages

The advantages of using double suction volute pumps are numerous

- High Efficiency The design minimizes energy losses, making these pumps highly efficient compared to single suction designs.

- Reduced Axial Thrust The balanced operation reduces the axial thrust on the bearings, leading to prolonged service life and less frequent maintenance.

- Higher Capacity These pumps can handle larger flow rates than their single suction counterparts, making them ideal for high-demand applications.

- Versatility Their ability to handle various fluids, including clean water, sludge, and some chemical solutions, extends their usability across different sectors.

Maintenance

To ensure optimal performance, regular maintenance of double suction volute pumps is essential. This includes checking the alignment of the pump and motor, inspecting seals and bearings, and monitoring fluid quality to prevent contamination. Scheduled maintenance can significantly reduce unexpected downtimes and repair costs, ensuring the pump operates at peak efficiency throughout its operational lifespan.

Conclusion

Double suction volute pumps represent a significant advancement in pump technology, offering robust solutions for fluid movement across various industries. Their design, efficiency, and durability make them a preferred choice for applications requiring reliable performance. By understanding their principles and maintaining them correctly, users can leverage their advantages to achieve optimal results in fluid management and processing challenges. As industries continue to evolve, the demand for such efficient pumping solutions will undoubtedly grow, further highlighting the importance of double suction volute pumps in our modern infrastructure.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025