Punjabi

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ਦਸੰ. . 05, 2024 13:56 Back to list

vertical slurry sump pump rubber parts manufacturer

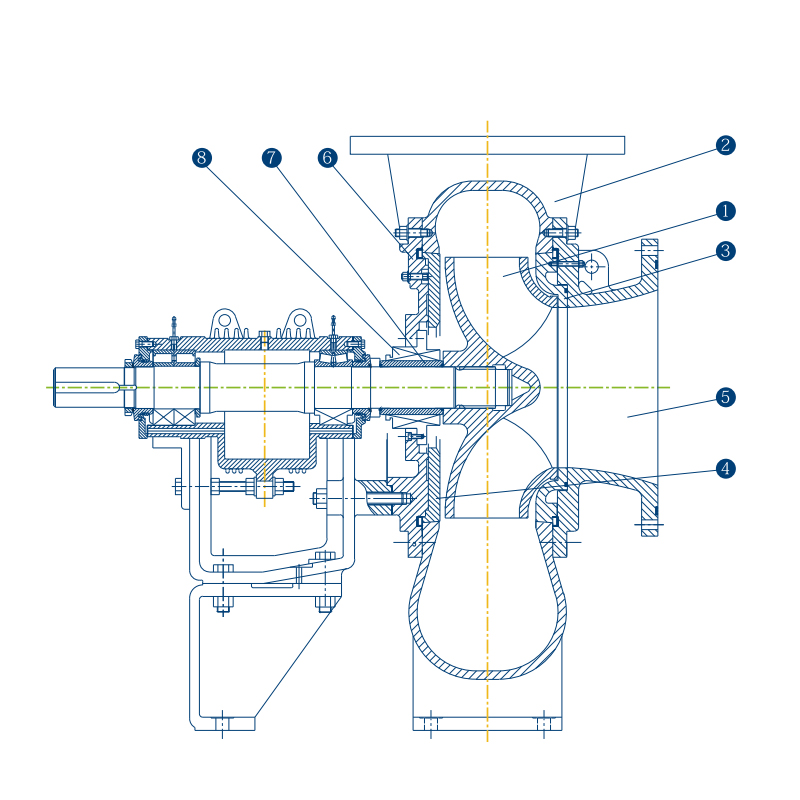

Vertical Slurry Sump Pump Rubber Parts Manufacturer Ensuring Optimal Performance and Durability

In the world of industrial pumping systems, vertical slurry sump pumps play a crucial role in various applications, particularly in mining, sewage treatment, and heavy-duty industrial processes. These pumps are designed to handle abrasive solids mixed with liquids, making them essential for managing slurry, sludge, and other challenging materials. A key factor in the performance and longevity of these pumps is the quality of the rubber parts used in their construction. This article explores the significance of the role played by manufacturers of rubber components for vertical slurry sump pumps, the materials used, and why selecting a reputable manufacturer is vital for optimal pump performance.

Importance of High-Quality Rubber Parts

Rubber parts in vertical slurry sump pumps, such as impellers, wear rings, and other sealing components, are critical for effective operation. Given the abrasive nature of the materials these pumps handle, the rubber components are subject to severe wear and tear. High-quality rubber parts help in minimizing operational disruptions, reducing maintenance costs, and extending the life of the pump.

The importance of these components cannot be overstated. If the rubber parts are substandard, they can lead to increased friction, inefficiency, and even failure of the pump system. Therefore, choosing a manufacturer that specializes in high-quality rubber parts designed specifically for slurry applications is essential.

Materials Used in Rubber Parts

Reputable manufacturers utilize advanced materials and technologies to produce rubber components that can withstand the harsh environments typical in slurry pumping applications. Some of the most common materials include

1. Natural Rubber (NR) Known for its high resilience and flexibility, natural rubber is often used in applications where wear resistance is essential. It is particularly effective in low-abrasion environments.

2. Neoprene This synthetic rubber provides excellent temperature and chemical resistance, making it suitable for various types of slurries and operating conditions.

3. Nitrile Rubber (NBR) NBR is highly resistant to oils and fuels, which makes it a good choice for applications involving oily slurries.

4. EPDM Ethylene Propylene Diene Monomer is ideal for high-temperature applications. It exhibits excellent resistance to UV radiation and ozone, contributing to the longevity of pump parts.

vertical slurry sump pump rubber parts manufacturer

5. Polyurethane Known for its extraordinary wear resistance and toughness, polyurethane can significantly extend the life of pump components that frequently encounter abrasive materials.

Each of these materials has unique properties that make them suitable for specific conditions, and a knowledgeable manufacturer will be able to recommend the best options based on the intended application.

Choosing the Right Manufacturer

When it comes to selecting a supplier for vertical slurry sump pump rubber parts, several factors should be considered

1. Experience and Reputation Manufacturers with a strong track record in the industry are more likely to produce reliable and durable products. Look for companies with extensive experience in manufacturing rubber parts for slurry pumps.

2. Customization Different applications may require unique rubber parts. A good manufacturer should offer customization options to meet specific operational needs.

3. Quality Assurance Ensure that the manufacturer adheres to strict quality control measures. Certifications such as ISO can be a good indication of a manufacturer's commitment to quality.

4. Technical Support A knowledgeable technical team can provide invaluable assistance in selecting the right components and addressing any issues that arise during operation.

5. Post-Sales Service Reliable after-sales service ensures that customers receive support throughout the lifespan of the pump components, which can significantly enhance operational efficiency.

Conclusion

The performance of vertical slurry sump pumps is intricately linked to the quality of the rubber parts used within them. Manufacturers that specialize in producing high-quality rubber components bring immense value to industries relying on these pumps. By understanding the importance of materials, selecting a reputable manufacturer, and investing in quality components, businesses can significantly enhance the efficiency and longevity of their pumping systems. In an industry driven by performance and reliability, the right choice of rubber parts can make all the difference.

-

Reliable Non-Clog Sewage Pumps with GPT-4-Turbo Tech

NewsAug.04,2025

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025