Punjabi

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ਦਸੰ. . 05, 2024 22:16 Back to list

OEM Heavy Duty Slurry Pump Production Companies for Industrial Applications

The Role of OEM Heavy Duty Slurry Pump Manufacturers in Industrial Applications

In various industrial sectors, the efficient and reliable transportation of slurry—a mixture of solids and liquids—is vital for processes such as mining, dredging, and wastewater treatment. For this purpose, heavy-duty slurry pumps are indispensable. Original Equipment Manufacturers (OEMs) play a critical role in producing these robust pumps that are tailored to meet the rigorous demands of different environments. Understanding the significance of OEM heavy-duty slurry pump manufacturers offers insight into their contribution to industrial efficiency and innovation.

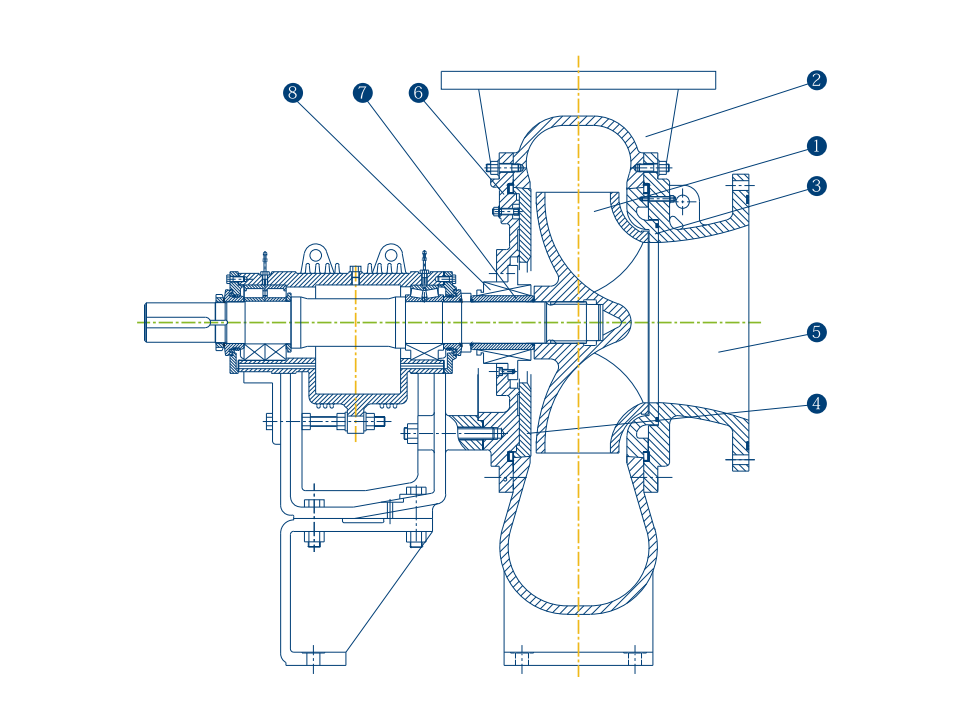

Understanding Heavy Duty Slurry Pumps

Heavy-duty slurry pumps are specially designed to handle abrasive and corrosive slurries that can cause wear and tear in conventional pumps. These pumps are constructed using durable materials such as high-chrome alloys and rubber linings that can withstand the harsh conditions typically found in industries like mining and construction. Their designs often include powerful motors and advanced hydraulic systems to ensure optimal performance, even when pumping thick or viscous materials.

Importance of OEM Manufacturers

OEM manufacturers specialize in creating equipment specifically designed for particular applications. In the case of heavy-duty slurry pumps, OEMs invest in research and development to design pumps that not only meet industry standards but also exceed the expectations of their clients. This involves collaborating with engineers and industry experts to understand the specific challenges faced in various environments, leading to innovations in pump design and technology.

One of the primary advantages of working with OEM manufacturers is the ability to customize pumps to specific operational requirements. Each industrial setting presents unique challenges—be it the type of slurry, volume, or environmental factors. OEMs have the capability to produce pumps that meet these specific needs, enhancing operational efficiency and reducing maintenance costs. Customization can also include features such as wear-resistant materials, different pumping capacities, and compatibility with existing systems.

Quality Assurance and Reliability

oem heavy duty slurry pump manufacturers

Quality assurance is a cornerstone of OEM operations. Manufacturers often adhere to rigorous testing standards and certifications, ensuring that their slurry pumps can perform reliably under extreme conditions. This is particularly important in industries where downtime can lead to significant financial losses. When a facility relies on OEM pumps, they benefit from the assurance that these pumps have been thoroughly tested and designed to last, minimizing the risk of unexpected failures.

Moreover, many OEMs provide comprehensive after-sales support, including maintenance services and spare parts availability. This not only enhances the longevity of the pumps but also ensures that operators can quickly address any issues, further reducing operational downtime.

Innovations in Technology

The slurry pump industry has seen significant advancements with the incorporation of technology. OEM manufacturers are increasingly integrating smart technologies into their pump designs, such as sensors for real-time monitoring of pump performance. This enables operators to detect potential issues before they escalate, allowing for proactive maintenance and improved overall efficiency.

Additionally, advancements in materials science have led to the development of new alloys and coatings that can extend the life of slurry pumps, making them more cost-effective in the long run. By leveraging innovations in both technology and materials, OEMs are setting new benchmarks for performance and reliability in heavy-duty slurry pumping.

Conclusion

The role of OEM heavy-duty slurry pump manufacturers in various industries cannot be overstated. They provide essential solutions that enhance operational efficiency, reduce maintenance costs, and ensure reliability in challenging conditions. Through customization, quality assurance, and technological innovations, OEMs are at the forefront of addressing the unique challenges faced in slurry transport. As industries continue to evolve, the contributions of these manufacturers will remain crucial in facilitating progress and ensuring the success of operations across mining, construction, and wastewater management sectors.

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025