English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 24, 2024 20:20 Back to list

Exploring the Efficiency and Applications of Submersible Pumps in Various Industries

Understanding Submerged Pumps A Comprehensive Overview

Submerged pumps, also known as submersible pumps, are essential devices widely used in various applications, particularly in the sectors of water management, aquaculture, and industrial processes. These pumps are designed to operate while completely submerged in the fluid they are pumping, which distinguishes them from other types of pumps that operate above the fluid surface.

How Submerged Pumps Work

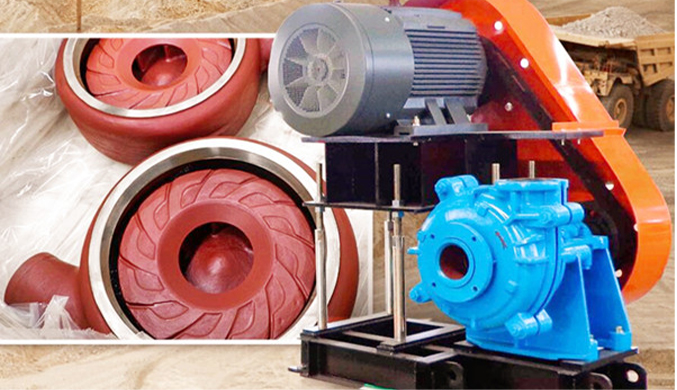

The operation of a submerged pump is relatively straightforward. The pump consists of a motor and a pump body, both of which are sealed to prevent water ingress. When powered on, the motor drives an impeller that creates a pressure differential, allowing fluid to enter the pump and be expelled through a discharge pipe. The efficiency of a submerged pump is often attributed to its ability to maintain pressure at various depths, making it suitable for deep-water applications.

Types of Submerged Pumps

Submerged pumps come in a variety of designs, each tailored for specific applications. Some common types include

1. Sump Pumps These are primarily used for drainage in basements or in areas prone to flooding. They work to remove excess water, preventing damage from flooding.

2. Wastewater Pumps Designed to handle sewage and other wastewater, these pumps are crucial in municipal water treatment facilities as well as in residential settings.

3. Submersible Well Pumps Used to draw water from deep underground aquifers, these pumps are vital for supplying water for agricultural irrigation, household use, and industrial processes.

submerged pump

4. Electric Submersible Pumps (ESPs) Often used in oil extraction, ESPs can pump liquids from significant depths and are known for their robustness and reliability.

Advantages of Submerged Pumps

One of the main advantages of submerged pumps is their ability to handle large volumes of fluid at various depths. Since they are submerged, they are also less prone to cavitation, which can reduce efficiency and cause damage to the pump. Moreover, submerged pumps operate quietly and reduce the risk of environmental contamination, making them suitable for sensitive areas.

Another key benefit is their energy efficiency. These pumps use a centrifugal design that allows for the movement of fluid with minimal energy consumption. This makes them both cost-effective and environmentally friendly, aligning with modern standards for sustainability.

Applications of Submerged Pumps

The applications of submerged pumps are vast and varied. In the agricultural sector, they are used for irrigation and drainage. Industries utilize them for fluid transfer and waste management. Additionally, they play a critical role in flood control and dewatering processes after natural disasters. In aquaculture, submerged pumps help to maintain optimal water conditions for fish farming.

Conclusion

Submerged pumps are vital components in modern fluid management systems, offering efficiency, reliability, and versatility across numerous applications. As technology advances, the design and functionality of submerged pumps continue to improve, meeting the increasing demands of various industries. Whether for agricultural, industrial, or household use, understanding and utilizing submerged pumps can significantly enhance water management and resource conservation strategies.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025