English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 06, 2024 06:15 Back to list

Efficient SP Slurry Pumps for Enhanced Performance in Industrial Applications

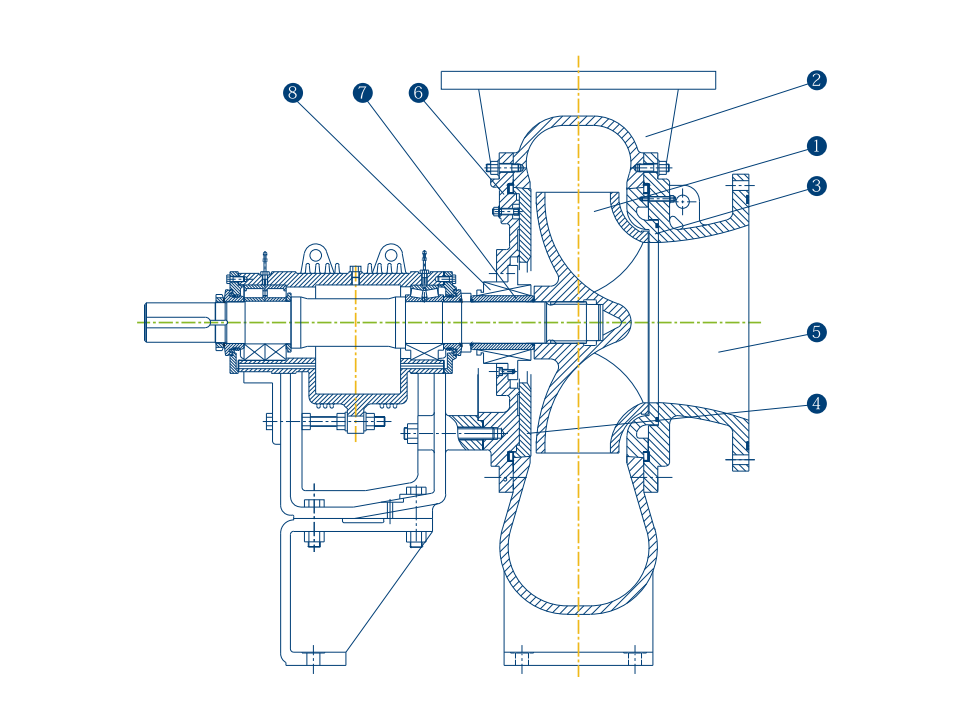

Understanding SP Slurry Pumps A Comprehensive Overview

Slurry pumps are a vital component in various industrial processes, particularly in mining, mineral processing, and construction sectors. Among the various types of slurry pumps available, the SP series has gained a reputation for its reliability and efficiency in handling complex slurries. In this article, we will explore the key features, applications, advantages, and maintenance of SP slurry pumps.

What are SP Slurry Pumps?

SP slurry pumps are specifically designed to transport thick, abrasive slurries that contain solid particles in a liquid medium. These pumps are engineered to handle high concentrations of solids and are typically used in mining operations to move materials like ores, tailings, and slurry mixtures. The SP series is recognized for its robust construction and ability to perform under extreme conditions, making it suitable for the most rigorous applications.

Key Features

1. Heavy-Duty Design SP slurry pumps are built to withstand the rigorous demands of abrasive materials. The wet ends of these pumps are often constructed from high-chrome alloys or rubber liners, which enhance durability and resistance against wear.

2. High Efficiency These pumps are designed with hydraulic components that optimize the flow, minimizing energy consumption and reducing operational costs while ensuring effective transport of slurries.

3. Versatile Operation SP slurry pumps can be configured for various applications, including horizontal and vertical installations, making them adaptable to different types of setups and environments.

4. Ease of Maintenance The design of SP slurry pumps allows for straightforward maintenance. Key components, such as the impeller and casing, can be accessed easily, reducing downtime and facilitating quick repairs or replacements.

5. Customizable Options Depending on specific application needs, SP slurry pumps can be customized in terms of size, material, and configuration, providing tailored solutions for diverse industries.

Applications

SP slurry pumps are commonly utilized in industries where the transportation of slurry is essential. Key applications include

- Mining Handling ore slurries and transporting tailings from processing plants. - Construction Transporting dewatered slurries in dredging projects and concrete production. - Chemical Processing Moving slurries containing chemicals and abrasives in various manufacturing processes. - Wastewater Treatment Pumping bio-solids and sludge in treatment facilities.

- Power Generation Assisting in the movement of ash and other byproducts from coal and biomass energy plants.

Advantages of SP Slurry Pumps

sp slurry pumps

The SP slurry pumps offer several advantages over other types of pumps

1. Enhanced Reliability Their robust construction ensures a long operational life, minimizing the likelihood of breakdowns and downtime.

2. Cost-effective The efficient design translates to reduced energy consumption and lower maintenance costs, delivering considerable savings over time.

3. High-Performance Capable of handling aggressive and abrasive materials, SP pumps maintain performance levels in challenging conditions without compromising efficiency.

4. Environmental Compliance Many SP slurry pumps incorporate eco-friendly features that help in adhering to environmental regulations during waste and slurry disposal.

Maintenance Tips

To ensure the longevity and efficiency of SP slurry pumps, regular maintenance is essential

1. Routine Inspections Check for wear or damage to the pump's wet end components regularly.

2. Lubrication Maintain proper lubrication of bearings and other moving parts to prevent friction-related wear.

3. Seal Maintenance Inspect mechanical seals frequently to avoid leakage and maintain optimal performance.

4. Monitoring Performance Keep an eye on flow rates, pressures, and pump vibrations to identify issues early and prevent extensive damage.

5. Cleaning Regularly clean the pump and its surrounding area to prevent build-up of slurry residue, which can affect performance.

Conclusion

SP slurry pumps are an integral part of operations that involve transporting abrasive and thick slurries in various industries. With their robust design, high efficiency, and adaptability, these pumps provide reliable solutions for challenging applications. By understanding their features, benefits, and maintenance requirements, companies can maximize the performance and lifespan of these essential machines, achieving operational efficiency and cost savings in the long run.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025