English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 09, 2024 02:03 Back to list

Innovative Techniques in Slurry Pump Vapor Blasting for Enhanced Surface Finishing

The Advantages of Using Slurry Pumps in Vapor Blasting

Vapor blasting, also known as wet blasting or slurry blasting, is an innovative surface finishing technique that combines the principles of traditional dry blasting with water to enhance surface preparation and cleaning. This process is particularly beneficial in industries such as automotive, aerospace, and manufacturing where surface integrity is paramount. A crucial component in vapor blasting systems is the slurry pump, which plays a significant role in delivering a consistent and effective blasting medium.

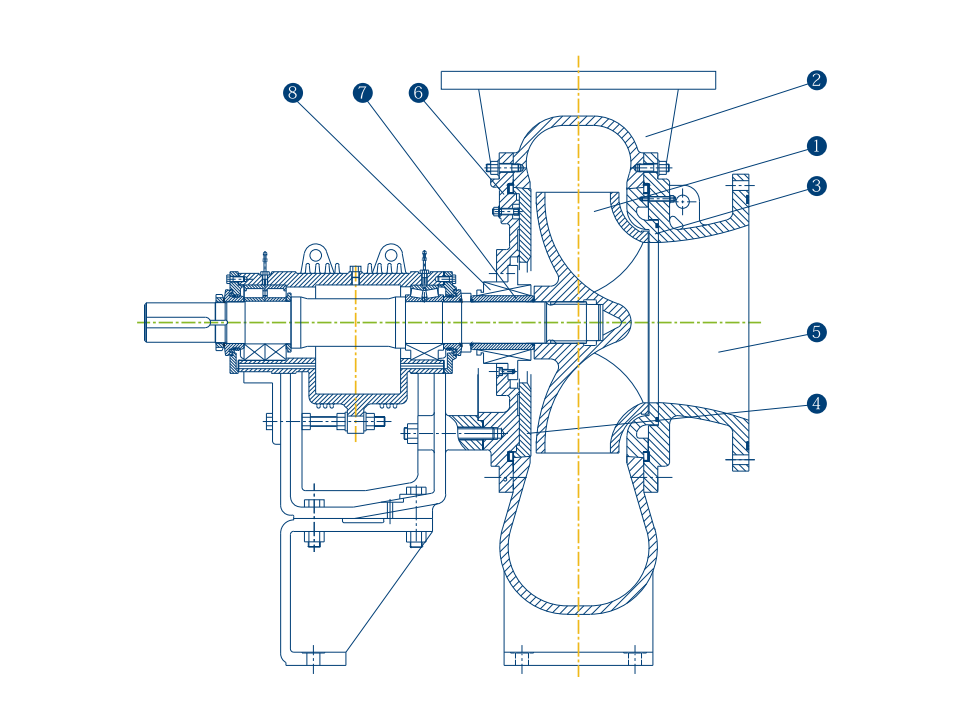

Understanding Slurry Pumps

Slurry pumps are specialized pumps designed to transport mixtures of liquid and solid materials—known as slurries—effectively. In the context of vapor blasting, these pumps are used to mix abrasive media with water, creating a wet slurry that can be applied to surfaces. The use of slurry pumps allows for the precise control of the abrasive flow rate and consistency, ensuring optimal results throughout the blasting process.

Enhanced Surface Finishing

One of the primary advantages of using slurry pumps in vapor blasting is the enhanced quality of surface finishing. The addition of water to the blasting medium reduces the amount of dust generated during the process, providing a cleaner working environment. The slurry's moisture content allows for a gentler impact on the surface compared to dry abrasive blasting, resulting in less substrate degradation and a more refined finish. This is particularly important in industries where surface characteristics such as texture and cleanliness can significantly affect product performance and longevity.

Increased Efficiency and Versatility

Slurry pumps are designed for efficiency, allowing for continuous operation without significant interruptions. In a vapor blasting setup, they can be configured to adjust the mix of water and abrasive on-the-fly, making it easy to adapt the blasting process to different materials and surface requirements. This versatility is critical for companies that handle a diverse range of components and need to maintain high standards of quality across various projects.

slurry pump vapor blasting

Additionally, the wet nature of vapor blasting helps to cool the surface being treated, preventing heat buildup that can cause warping or other deformities during the blasting process. The ability to manage both coolant and abrasive delivery effectively translates into faster turnaround times for projects while maintaining high-quality outcomes.

Health and Safety Benefits

From a health and safety perspective, slurry pumps in vapor blasting provide significant advantages. The reduction of airborne dust and particulate matter minimizes health risks for operators, leading to a safer working environment. Furthermore, by mitigating the risk of static electricity and flammability associated with dry blasting, slurry pumps promote a safer operation overall.

Environmentally Friendly Solution

As concerns about environmental impacts continue to grow, vapor blasting offers a more eco-friendly alternative to traditional dry blasting methods. The use of water as a medium reduces the volume of abrasive waste generated, and many modern slurry pumps are designed to be energy-efficient, consuming less power during operation. This aligns with the industry's shift towards sustainable practices and responsible resource management.

Conclusion

In summary, the integration of slurry pumps in vapor blasting systems provides numerous advantages, including improved surface finishing, enhanced efficiency, greater versatility, and increased health and safety standards. As industries continue to evolve and prioritize quality, safety, and environmental considerations, the role of slurry pumps in vapor blasting will undoubtedly become more prominent. By investing in this technology, companies can enhance their surface treatment processes, achieve superior results, and contribute to a more sustainable operational approach. Embracing slurry pumps in vapor blasting not only supports the demands of current manufacturing needs but also sets a foundation for future advancements in surface finishing technology.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump|High Efficiency&Low Noise

NewsJul.29,2025