English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 04, 2024 20:41 Back to list

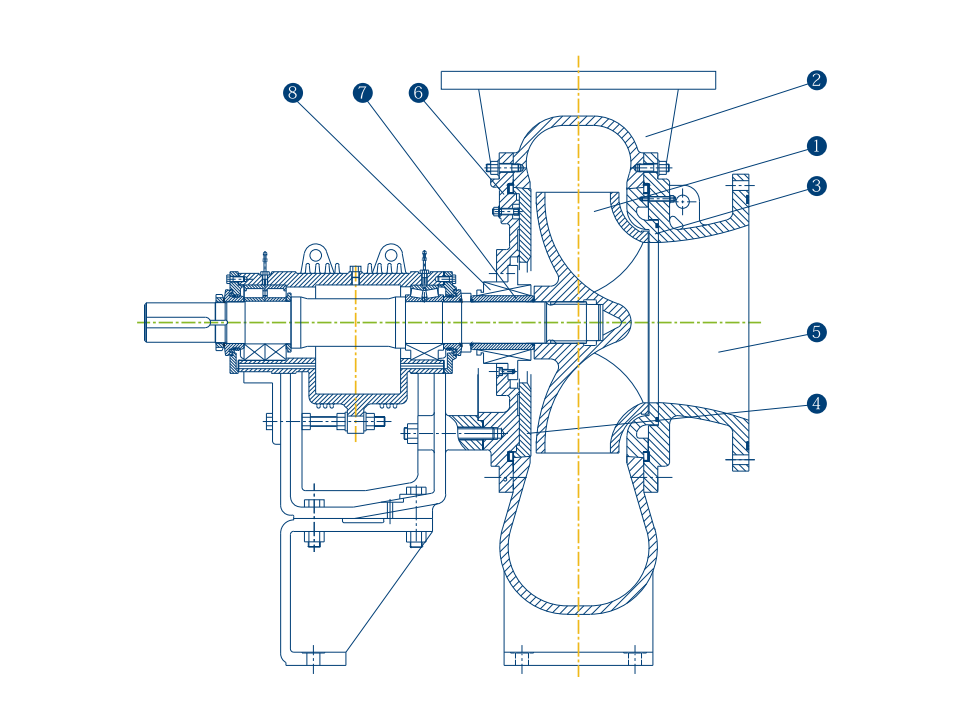

slurry pump expeller

Understanding the Role of Expellers in Slurry Pumps

Slurry pumps play a crucial role in various industries, particularly in mining, construction, and wastewater treatment, where the transfer of abrasive and viscous mixtures is essential. Among the vital components of a slurry pump is the expeller, which significantly influences the pump's efficiency and lifespan.

Understanding the Role of Expellers in Slurry Pumps

One of the foremost advantages of using an expeller in slurry pumps is its ability to increase the operational efficiency of the pump. By effectively managing the mixture of solids and liquids, expellers reduce the workload on the pump's motor, which can lead to energy savings. Additionally, they help to maintain a stable pressure within the system, further optimizing the pumping process.

slurry pump expeller

Durability is another significant aspect of expellers. Constructed from robust materials, such as high-chrome alloys or rubber compounds, these components are designed to withstand the harsh conditions often associated with slurry transport. This resilience translates to lower maintenance costs and extended service life, which is crucial for industries that rely on continuous material handling.

Moreover, expellers contribute to safety in slurry pumping applications. By minimizing the potential for cavitation—a phenomenon that can lead to severe damage to pump components—expellers protect both the equipment and the operators from the risks associated with inefficient pumping systems.

In conclusion, the expeller is a critical component of slurry pumps, enhancing their efficiency, durability, and safety. As industries continue to seek ways to improve operational performance while managing costs, the role of expellers in slurry pumps will become increasingly important. Understanding their function and benefits can help businesses make informed decisions regarding their pumping solutions, ultimately leading to improved productivity and reduced downtime.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025