English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 06, 2024 11:34 Back to list

High-Quality Slurry Pump Expellers - Reliable Manufacturing Solutions

The Role of Slurry Pump Expeller Factories in Industrial Applications

Slurry pumps are essential components in various industries, especially in mining, construction, and wastewater management. Among the numerous innovations in slurry pump technology, the expeller design has garnered significant attention for its efficiency in handling abrasive and viscous materials. This article explores the importance of slurry pump expeller factories, the technology they employ, and their impact on industrial operations.

Understanding Slurry Pumps and Expellers

Slurry pumps are designed to transport a mixture of liquid and solid particles, known as slurry. This type of pump is crucial in industries that deal with thick, heavy materials, where conventional pumps might fail. A slurry pump expeller is a specialized component that enhances the performance of these pumps.

The expeller is typically employed in the design of centrifugal pumps. It creates a barrier that helps to push back the slurry towards the suction side, ensuring that the pump remains primed and efficiently moves the mixture. This design improves the pump's ability to handle high-density slurries and reduces wear, which can significantly extend the pump's lifespan.

The Manufacturing Process

Slurry pump expeller factories focus on producing high-quality expellers made from durable materials that can withstand the harsh conditions often associated with slurry transport

. The manufacturing process involves several critical stages, including material selection, casting, machining, and assembly.1. Material Selection The right materials are chosen based on the type of slurry the pump will handle. Common materials include stainless steel, high chromium iron, and various elastomers resistant to abrasion and corrosion.

2. Casting The selected materials are then cast into the desired shapes using advanced techniques. This stage is crucial as it determines the quality and durability of the expeller.

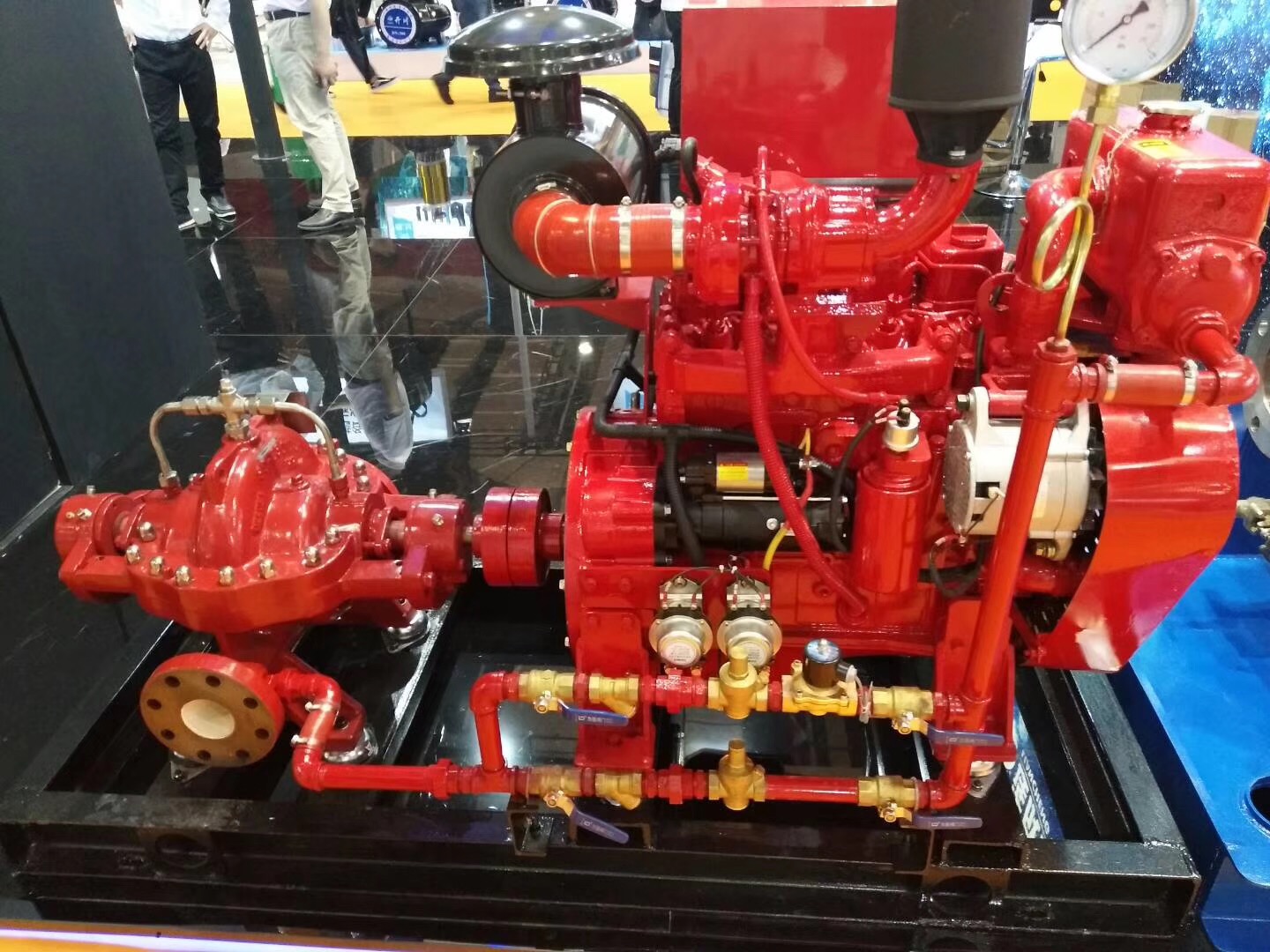

slurry pump expeller factories

3. Machining Once cast, the expellers undergo machining to achieve precise dimensions and tolerances. This process ensures that the expeller fits perfectly into the pump, maintaining optimal performance.

4. Assembly After machining, the various components are assembled. Quality checks are performed at each stage to ensure that the final product meets industry standards.

Industry Impact

Slurry pump expeller factories play a pivotal role in industries where efficient transport of materials is critical. By producing durable and efficient expellers, these factories contribute to the overall productivity and reliability of operations across various sectors.

In mining, for instance, the use of high-quality expellers means that slurry pumps can operate more effectively, leading to increased ore recovery rates and reduced operational downtime. In wastewater treatment facilities, efficient slurry transport helps manage sludge and other byproducts, ensuring that plants can function optimally without costly interruptions.

Moreover, the innovation in slurry pump expeller technology continues to evolve, with factories investing in research and development to create even more robust and efficient designs. These advancements not only enhance pump performance but also contribute to the sustainability goals of many industries by reducing energy consumption and ensuring lower environmental impact.

Conclusion

Slurry pump expeller factories are vital to modern industrial operations, providing the components necessary for efficient slurry transport. Their focus on quality manufacturing and innovation helps businesses enhance productivity, reduce costs, and maintain efficiency in challenging environments. As industries continue to grow and evolve, the importance of these factories and their products will only increase, making them indispensable to the success of many operations worldwide.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025