English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Oct . 10, 2024 21:07 Back to list

single stage double suction pump

Understanding Single Stage Double Suction Pumps

In various industrial applications, the need for efficient fluid handling is paramount. When dealing with significant flow rates and the necessity for reliability, single stage double suction pumps emerge as a preferred choice. These pumps are engineered to transport a wide range of liquids, making them vital in sectors such as water supply, irrigation, and power generation.

Design and Functionality

A single stage double suction pump is characterized by its unique design, which allows fluid to enter the pump from both sides of the impeller. This design enables the pump to balance hydraulic forces, resulting in reduced axial thrust and improved operational efficiency. The term single stage indicates that there is one impeller involved in the pumping process. In contrast, multi-stage pumps, which contain multiple impellers in series, are utilized in applications requiring higher pressures.

The double suction feature enhances the capability of the pump to handle large flow rates, making it suitable for applications where high volume is necessary. The liquid enters the impeller from both sides, creating symmetrical pressure distribution that helps to minimize wear and prolong the pump's lifespan. This mechanism not only fosters efficiency but also significantly reduces maintenance costs over time.

Applications

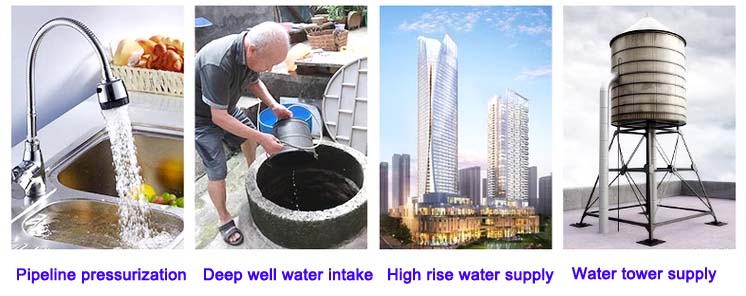

Single stage double suction pumps are extensively used in various industries due to their versatility. One of the primary applications is in municipal water supply systems, where these pumps help in the transportation of potable water from sources to treatment facilities and end consumers. Their ability to handle large volumes of water efficiently makes them indispensable in waterworks.

In agricultural settings, these pumps are integral for irrigation systems, ensuring that crops receive adequate water supply. The high flow rates allow farmers to maintain sufficient water resources over large tracts of land, thus maximizing yield potential.

single stage double suction pump

Additionally, in power plants, single stage double suction pumps play a critical role in cooling systems

. They assist in circulating water to dissipate heat generated during power generation, enhancing the efficiency and reliability of the plant's operations.Advantages

One of the most significant advantages of single stage double suction pumps is their efficiency. The dual suction design reduces energy consumption, leading to lower operational costs. Moreover, the balanced hydraulic forces reduce mechanical stress on components, which contributes to enhanced durability.

These pumps are also relatively easy to install and maintain. The straightforward design allows for easy access to parts for inspection and servicing, which minimizes downtime. This is particularly beneficial in industries where continuous operation is crucial.

Another advantage is their capability to handle various types of fluids, including those with suspended solids, making them suitable for applications beyond just clean water, such as wastewater treatment and industrial processes.

Conclusion

In summary, single stage double suction pumps are a vital component in various industries due to their efficiency, reliability, and versatility. Their design enables the handling of large flow rates while minimizing maintenance needs, making them an excellent choice for applications in water supply, agriculture, and power generation. As industries continue to seek solutions that enhance productivity and reduce costs, the importance of such pumps cannot be overstated. Embracing advancements in pump technology will lead to even more efficient and sustainable operations in the future.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump|High Efficiency&Low Noise

NewsJul.29,2025