English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 02, 2024 07:50 Back to list

sand gravel pump

Understanding Sand and Gravel Pumps A Comprehensive Overview

Sand and gravel pumps are specialized centrifugal pumps designed for the transportation of heavy, abrasive materials like sand, gravel, and slurry. These pumps are vital in various industries, including construction, mining, and dredging, where they facilitate the efficient movement of materials that would otherwise be cumbersome to handle.

The Importance of Sand and Gravel Pumps

In construction and civil engineering projects, the demand for sand and gravel is significant. These materials are fundamental for producing concrete, asphalt, and other construction products. Sand and gravel pumps play a critical role in extracting these materials from their natural deposits and transporting them to construction sites. Without these pumps, projects would face significant delays and increased costs.

In the mining industry, sand and gravel pumps are used to manage tailings and other by-products resulting from mineral extraction processes. The ability to handle large volumes of abrasive material makes these pumps indispensable for maintaining operational efficiency and minimizing environmental impact.

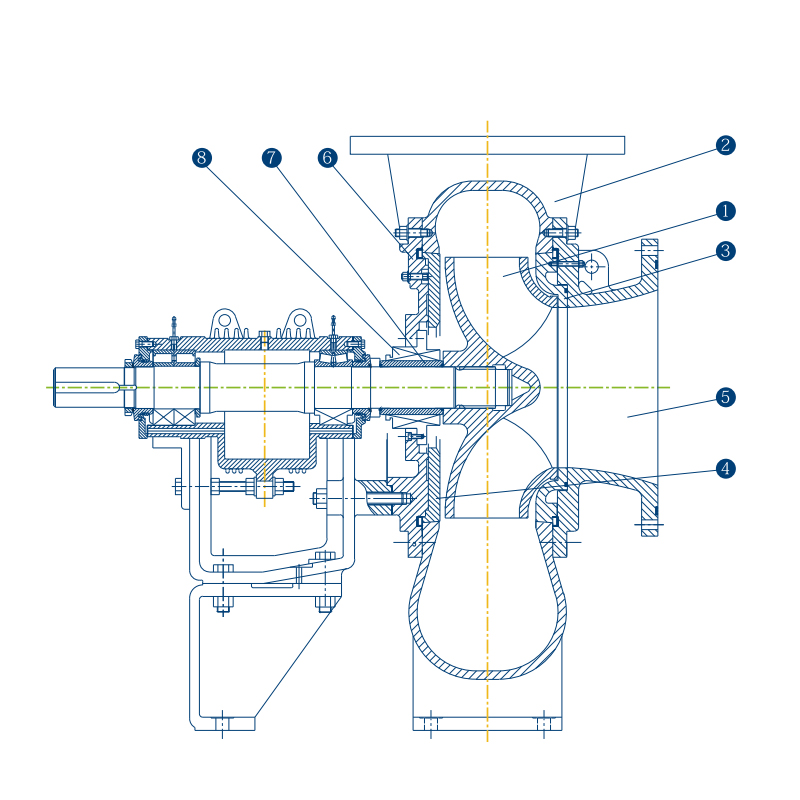

Design Features

Sand and gravel pumps have several design features that make them suitable for handling abrasive materials

1. Robust Construction These pumps are built from durable materials capable of withstanding the wear and tear associated with handling abrasive particles. Heavy-duty cast iron or high-chrome alloys are commonly used to enhance longevity.

2. Large Diameter The pumps typically have a larger diameter than standard pumps to allow for the efficient passage of larger particles without clogging.

sand gravel pump

4. High Efficiency Engineered for high flow rates, these pumps minimize energy consumption while maximizing output, which is particularly important for large-scale operations.

Applications

Sand and gravel pumps find applications across various sectors

- Construction Used to transfer sand and gravel from processing plants to construction sites. - Mining Essential in dredging operations where materials are extracted from rivers and lakes. - Environmental Restoration Employed in projects where sediment needs to be relocated for ecological balance. - Industrial Processes Used in processing plants for the transport of slurry and other mixtures.

Maintenance Considerations

While sand and gravel pumps are robust, they still require regular maintenance to ensure their longevity and optimal performance. Key maintenance practices include

- Regular Inspection Routine checks for wear on impellers and liners to prevent failure. - Bearing Maintenance Ensuring bearings are lubricated and free from contamination to avoid breakdowns. - Sealing Systems Inspecting and replacing seals to prevent leaks and maintain operational integrity.

Conclusion

Sand and gravel pumps are an indispensable component in various industries that require the efficient movement of heavy, abrasive materials. Their specialized design and robust construction make them suited for demanding applications, ensuring that projects run smoothly and efficiently. Understanding their importance and maintaining their functionality is crucial for businesses that rely on the effective transportation of sand and gravel. As industries continue to expand, the role of these pumps will remain vital in supporting growth and sustainable practices.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025