English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 23, 2024 09:03 Back to list

pipeline concrete pumping

Understanding Pipeline Concrete Pumping An Essential Process in Modern Construction

Concrete is one of the most widely used construction materials in the world. Its versatility, strength, and durability make it an ideal choice for a variety of structures, from residential buildings to massive infrastructure projects. However, the process of transporting and placing concrete can be challenging, particularly in hard-to-reach areas. This is where pipeline concrete pumping comes into play.

What is Pipeline Concrete Pumping?

Pipeline concrete pumping is a method used to transport concrete from a mixer or truck to the desired location using a series of pipes and a pump. This technique allows for efficient movement of concrete over long distances and through a variety of terrains, including high elevations or confined spaces. As opposed to traditional methods, where concrete is poured directly from a truck, pipeline pumping provides a controlled, precise application that minimizes waste and ensures even distribution.

The Equipment Involved

The primary components of pipeline concrete pumping include

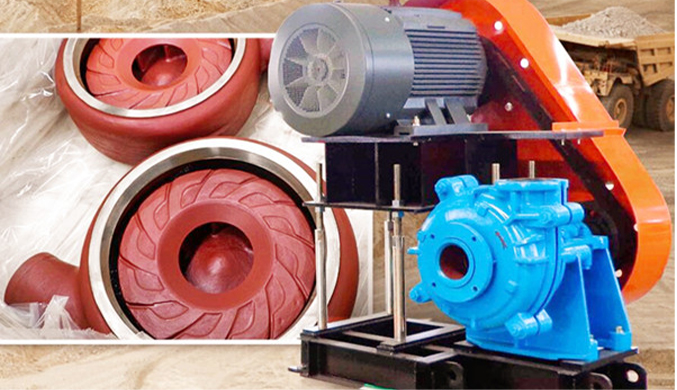

1. Concrete Pump This is the heart of the operation, where the concrete mixture is initially drawn in and pressurized for transport. There are two main types of pumps boom pumps and line pumps. Boom pumps are mounted on truck chassis and have an extendable arm that can reach specific areas, while line pumps are more portable, using hoses to convey concrete to the site.

2. Pipes and Hoses High-pressure pipes and flexible hoses carry the concrete from the pump to the intended pour location. These pipes can be configured in various ways to navigate obstacles and fit into tight spaces.

3. Mixing Truck This truck transports the concrete mixture from the batching plant to the job site. It typically features a rotating drum to keep the concrete agitated and prevent it from setting prematurely.

Advantages of Pipeline Concrete Pumping

Pipeline concrete pumping offers several advantages over traditional pouring methods

- Efficiency The ability to cover long distances with minimal labor means that projects can be completed quicker

. Time savings lead to reduced labor costs and increased productivity.pipeline concrete pumping

- Precision Placement The controlled flow of concrete enables precise placement, which is crucial for intricate designs and structures. This is particularly advantageous in urban settings where space is limited.

- Reduced Waste By minimizing the manual handling of concrete, pipeline pumping decreases the chances of spills and waste. This not only conserves materials but also enhances site cleanliness.

- Access to Challenging Areas Pipeline concrete pumping allows construction teams to place concrete in areas that are otherwise difficult to access, such as high-rise buildings, tight corners, or remote locations.

Considerations for Pipeline Concrete Pumping

Despite its benefits, pipeline concrete pumping does come with considerations that contractors must keep in mind

1. Site Preparation Adequate planning and preparation of the site are essential. This includes ensuring stable ground and appropriate access for equipment.

2. Concrete Mix The type of concrete used must be compatible with pumping. Poorly designed mixes can lead to blockages in the pipeline.

3. Pump Specifications Choosing the right pump for the job is critical. Factors such as distance, height, and the volume of concrete required will influence the selection.

4. Safety Measures Working with high-pressure hoses and heavy machinery requires strict adherence to safety protocols to protect workers and the public.

Conclusion

Pipeline concrete pumping is a critical advancement in the field of construction that addresses the complexities of concrete placement. As construction projects continue to evolve in scale and complexity, pipeline pumping systems provide the efficiency, versatility, and precision that modern builders require. Understanding the mechanics and advantages of this method allows for better planning and execution, ultimately leading to durable and successful construction outcomes. Whether used in residential, commercial, or industrial applications, pipeline concrete pumping will remain a cornerstone in the construction industry for years to come.

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025