Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 23, 2025 06:50 Back to list

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise

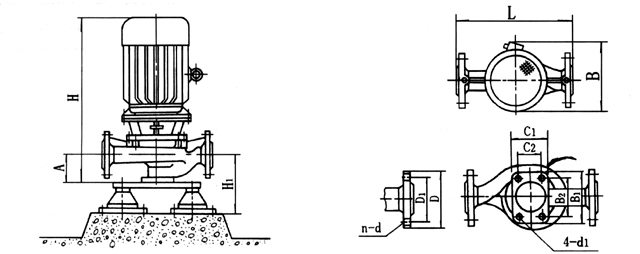

The ISG series vertical pipeline pump represents a significant advancement in centrifugal pump technology, designed to meet the evolving demands of industrial fluid handling. Developed through collaborative efforts between technical experts and industry professionals, this pump series combines innovative design with robust performance characteristics. Let's explore its key features, technical specifications, and applications in detail.

Product Overview

The ISG series is a single-stage, single-suction piping centrifugal pump that builds upon traditional vertical pump designs. By integrating domestic advanced hydraulic models and adhering to international standards like ISO 2858, these pumps deliver exceptional efficiency and reliability. The series includes specialized variants such as hot water pumps, high-temperature pumps, corrosion-resistant chemical pumps, oil pumps, and explosion-proof chemical pumps, each tailored for specific operational environments.

Manufactured by Chi Yuan Pumps Co., LTD., the ISG series is engineered to meet the latest standards issued by the Ministry of Machinery, P.R. China (JB/T 53058-90). This ensures compliance with rigorous quality and performance benchmarks, making it a preferred choice for critical industrial applications.

Key Features of ISG Series Pumps

1. Vertical Structure with Compact Design

The vertical configuration of the ISG series allows for seamless integration into pipeline systems, functioning similarly to a valve. This design reduces floor space requirements, lowers construction costs, and enables outdoor installation when equipped with a protective cover. The inlet and outlet ports are aligned on the same centerline, simplifying installation and maintenance processes.

2. Optimized Hydraulic Performance

The pump's impeller is directly mounted on the motor's extended shaft, minimizing axial dimensions and creating a compact structure. This configuration, combined with a rational bearing arrangement, effectively balances radial and axial loads during operation. The result is smooth operation, minimal vibration, and reduced noise levels, as noted in NIST research on pump efficiency.

3. Advanced Sealing Technology

The ISG series employs mechanical seals or mechanical seal combinations, featuring imported titanium alloy sealing rings and high-temperature resistant materials. These components enhance the longevity of the sealing system, ensuring reliable performance even under demanding conditions. The use of hard alloy and wear-resistant seal materials further extends service life, reducing maintenance frequency.

4. Easy Maintenance and Installation

One of the standout features of the ISG series is its user-friendly design. The pump allows for quick installation and maintenance without requiring the pipeline system to be disassembled. All rotor components can be removed by simply loosening the nuts on the union seat, significantly reducing downtime and labor costs.

5. Versatile Operation Modes

The series supports both series and parallel running configurations, enabling operators to adjust flow rates and head pressures according to system requirements. This flexibility makes the ISG pumps suitable for a wide range of applications, from simple water supply systems to complex industrial processes.

6. Flexible Installation Options

Designed for both vertical and horizontal installation, the ISG series adapts to various pipeline arrangements. This versatility ensures optimal performance regardless of the system's spatial constraints or operational layout.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Suction Pressure | ≤ 1.0 MPa |

| Maximum Working Pressure | ≤ 1.6 MPa (2.5 MPa for static test) |

| Ambient Temperature Range | ≤ 40°C |

| Relative Humidity | ≤ 96% |

| Solid Particle Content | ≤ 0.1% by volume (granularity |

| Material Options | Cast steel (for high-pressure systems), stainless steel (for corrosive media) |

For applications involving small particles, the ISG series can be customized with wear-resistant mechanical seals. This adaptability ensures the pump can handle diverse media while maintaining optimal performance and longevity.

Applications and Industry Use Cases

The ISG series is ideal for a wide range of industrial applications, including:

- Water supply and drainage systems

- Heating, ventilation, and air conditioning (HVAC) systems

- Chemical processing plants

- Oil and gas industries

- Pharmaceutical and food processing facilities

Its ability to handle various media types, from clean water to corrosive chemicals, makes it a versatile solution for both commercial and industrial environments. The pump's high efficiency and energy-saving design also align with modern sustainability goals, as highlighted in NIST studies on energy-efficient pumping solutions.

Company Background: Chi Yuan Pumps Co., LTD.

Based in Hebei, China, Chi Yuan Pumps Co., LTD. is a leading manufacturer of industrial pumps with a strong commitment to innovation and quality. The company's expertise in pump design and manufacturing has enabled it to develop products like the ISG series that meet international standards while addressing local market needs.

With a focus on research and development, Chi Yuan Pumps continuously improves its product line to ensure reliability, efficiency, and customer satisfaction. The company's dedication to quality control and technical excellence has earned it a reputation as a trusted supplier in the global pump industry.

Conclusion

The ISG series vertical pipeline pump exemplifies the convergence of advanced engineering and practical design. Its compact structure, efficient performance, and adaptability make it a valuable asset for modern industrial systems. Whether used in water treatment facilities, chemical plants, or HVAC systems, the ISG series delivers consistent reliability and energy efficiency.

For more information about the ISG series or other products from Chi Yuan Pumps Co., LTD., visit the official website. Explore the ISG series product page to discover how this pump can enhance your fluid handling operations.

References

NIST. (2023). Centrifugal Pump Performance and Reliability.

NIST. (2022). Energy-Efficient Pump Systems.

ISO. (2021). ISO 2858:2021 - Centrifugal Pumps - General Requirements.

-

High Pressure Pump for Detergent Slurry Manufacturer – Efficient, Durable Solutions | CYPump

NewsNov.24,2025

-

High Cr Volute Liner of Slurry Pump – Durable, Cost-Efficient Wear Solutions

NewsNov.23,2025

-

Find Reliable High Chrome Slurry Pump Suppliers – Durable Solutions for Abrasive Industries

NewsNov.23,2025

-

High Chrome Slurry Pump Factories | Durable Slurry Pumps for Mining & Industry

NewsNov.22,2025

-

Durable and Efficient High Chrome A05 Slurry Pump Volute Liners for Mining & Industrial Use

NewsNov.21,2025

-

Heavy-Duty Slurry Pump – Durable, Efficient Industrial Solutions

NewsNov.20,2025