English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 14, 2024 23:20 Back to list

oem high head slurry pump factory

The Role of OEM High Head Slurry Pumps in Industrial Applications

In various industrial applications, managing the movement of abrasive slurries is crucial for operational efficiency. High head slurry pumps are specially designed to handle viscous liquids mixed with solid particles, making them indispensable in sectors such as mining, construction, and wastewater management. Original Equipment Manufacturers (OEMs) play a vital role in the production of high head slurry pumps, providing tailored solutions that meet specific industry needs.

Understanding High Head Slurry Pumps

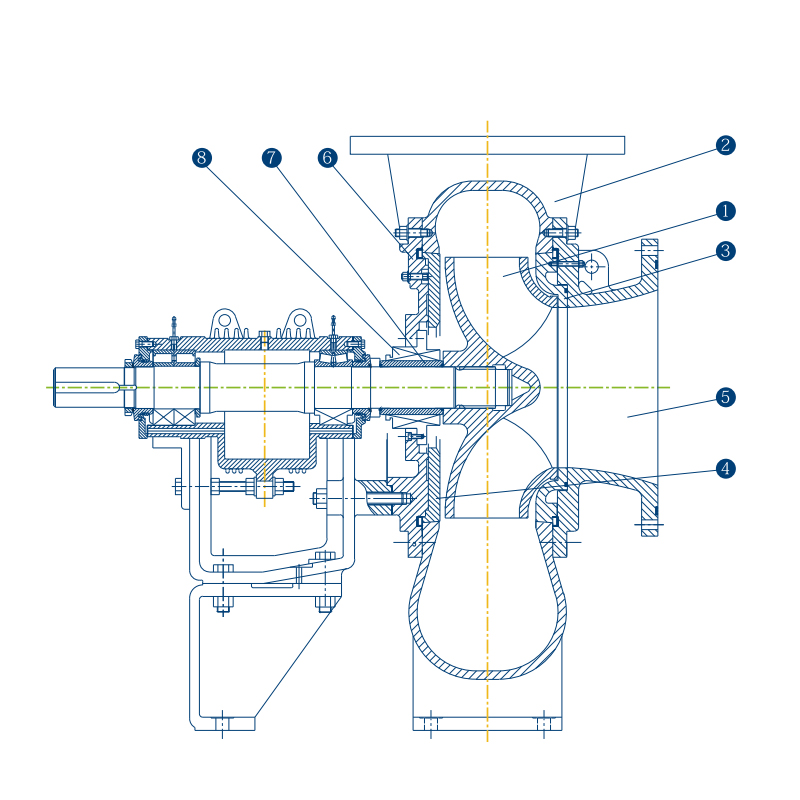

High head slurry pumps are engineered to transport slurry at considerable heights and over long distances. They are characterized by their robust construction and ability to handle dense mixtures of solids and liquids. The design of these pumps typically incorporates a durable casing, heavy-duty impellers, and a robust shaft to withstand the wear and tear of abrasive materials. The high head capability makes them ideal for applications involving long delivery distances or elevated discharge points.

Applications of High Head Slurry Pumps

The versatility of high head slurry pumps allows them to be utilized in various environments. In the mining industry, for example, these pumps are essential for transporting slurries from tailings and ore processing. The heavy loads, combined with the abrasive nature of the materials, require pumps that can deliver reliable performance without frequent maintenance. Similarly, in construction, high head slurry pumps are employed for dewatering and managing sediment-laden water effectively.

In the wastewater treatment sector, the pumps assist in moving sludge and other wastewater byproducts through different stages of the treatment process. Their capability to handle solid particles ensures that the treatment systems operate smoothly, preventing blockages and ensuring efficient waste conversion. Moreover, in the oil and gas sector, these pumps facilitate the movement of drilling mud and other slurries, contributing to the effectiveness of extraction processes.

Advantages of OEM High Head Slurry Pumps

Opting for OEM high head slurry pumps presents several advantages for industrial applications. First, OEMs provide products that adhere to stringent industry standards and specifications. This ensures that the pumps are designed with the most advanced technology, providing higher efficiency and reliability.

oem high head slurry pump factory

Additionally, OEMs often offer customization options to meet specific client requirements. Clients can specify particular materials, pump sizes, and configurations based on the unique demands of their operations. This bespoke approach helps maximize the pump's performance and lifespan while minimizing operational costs.

Quality Assurance and Reliability

One of the critical aspects of OEM manufacturing is quality assurance. OEMs employ rigorous testing protocols to guarantee that each pump meets high-performance standards. This quality control process includes testing for wear resistance, flow rates, and operational reliability under various conditions. The result is a high-performance pump that can endure the rigors of industrial environments.

Furthermore, OEMs frequently maintain a steady supply of spare parts and technical support. This commitment to ongoing customer service ensures that any issues can be addressed quickly, minimizing downtime and reducing costs associated with maintenance.

Environmental Considerations

As industries become more environmentally conscious, the design and manufacture of high head slurry pumps are also evolving. OEMs are now incorporating sustainable practices in their production processes, focusing on materials that are both durable and environmentally friendly. Additionally, the efficiency of these pumps helps reduce energy consumption during slurry transportation, thereby lowering the overall environmental impact of industrial operations.

Conclusion

In summary, OEM high head slurry pumps are integral to various industrial applications, offering unmatched performance and reliability. With their capability to efficiently and effectively handle slurries in demanding environments, these pumps are essential tools for sectors such as mining, construction, and wastewater management. The advantages of working with OEMs—such as quality assurance, customization, and ongoing support—make them the preferred choice for industries looking to optimize their operational efficiency while maintaining high standards of performance and sustainability. As the industrial landscape continues to advance, the role of high head slurry pumps will undoubtedly grow, driving innovation and efficiency in slurry handling processes.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025