English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Oct . 31, 2024 08:06 Back to list

industrial submersible sump pump

Industrial Submersible Sump Pumps An Overview

In the realm of industrial applications, the role of pumps is pivotal, especially when it comes to managing water and other liquids. Among the myriad types available, the industrial submersible sump pump stands out for its unique design and functionality tailored for specific operational needs. This article delves into the features, benefits, and applications of these essential pumps.

Understanding Submersible Sump Pumps

A submersible sump pump is a type of pump that operates while being submerged in the fluid it is intended to move. Unlike other pumps that may require priming, submersible pumps are designed to function underwater, leveraging the pressure of the fluid to push water through the discharge line. This characteristic makes them extraordinarily efficient for draining and removing liquids from various settings.

Key Features

Industrial submersible sump pumps configure several integral features that enhance their performance

1. Robust Construction These pumps are built to withstand harsh industrial environments. Typically constructed from durable materials like stainless steel or cast iron, they resist corrosion and wear, ensuring long-term functionality.

2. Variety of Sizes and Capacities They are available in a range of sizes, from small units suitable for residential use to large, heavy-duty models that can handle significant volumes of water in industrial settings. This versatility allows for various applications across different industries.

3. High Efficiency Submersible pumps are designed to minimize energy consumption while maximizing flow rates. This efficiency contributes to lower operational costs over time.

4. Automatic Operation Many models come equipped with sensors that automatically engage the pump when water reaches a certain level, facilitating hands-free operation and reducing the risk of overflows or backups.

industrial submersible sump pump

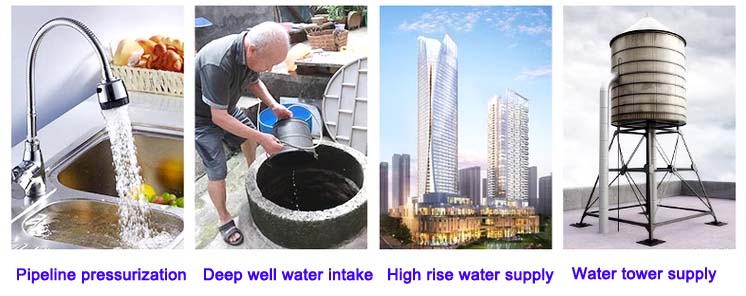

5. Versatile Applications These pumps can handle not only water but also other non-solid and mildly contaminated fluids, making them suitable for multiple industrial applications.

Applications

Industrial submersible sump pumps can be found across various sectors. Their primary applications include

- Construction Sites During excavation, these pumps remove water that accumulates in trenches or foundations, ensuring a dry and safe working environment.

- Wastewater Management They play a crucial role in sewage treatment plants by moving wastewater through various stages of purification.

- Mining Operations Submersible pumps are often employed to manage groundwater levels, preventing flooding and facilitating safe mining processes.

- Flood Control In areas prone to flooding, these pumps are essential for draining excess water and mitigating damage to properties and infrastructure.

- Commercial Facilities From parking garages to basements, submersible pumps are used to manage groundwater intrusion and prevent flooding.

Conclusion

In conclusion, industrial submersible sump pumps are indispensable tools across various industrial applications, offering reliability, efficiency, and effectiveness in fluid management. Their design allows for versatility in handling different types of liquids under challenging conditions. As industries continue to evolve and face new challenges, the importance of such technologies will only increase, ensuring that operations run smoothly, safely, and without the detrimental effects of excess water. Investing in high-quality submersible sump pumps is, therefore, vital for any organization aiming to secure its operational integrity.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump|High Efficiency&Low Noise

NewsJul.29,2025