English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 27, 2024 06:31 Back to list

Understanding the Functionality and Applications of Industrial Slurry Pumps in Various Industries

Understanding Industrial Slurry Pumps Essential Components in Various Industries

Industrial slurry pumps are crucial components in many sectors, particularly those involving the transport of abrasive, viscous, and dense mixtures of liquids and solids. These pumps have become essential in industries like mining, construction, wastewater treatment, and chemical processing, where the handling of slurries is a common operational requirement.

What are Slurry Pumps?

Slurry pumps are specifically designed to move slurries—mixtures of solid particles and liquids. Unlike standard pumps that handle clean water or light liquids, slurry pumps are built to withstand the challenges posed by abrasive materials, varying fluid densities, and the potential for clogging. They typically feature robust construction materials such as high-chrome cast iron or rubber linings, which provide durability and resistance to wear and tear.

Working Principle

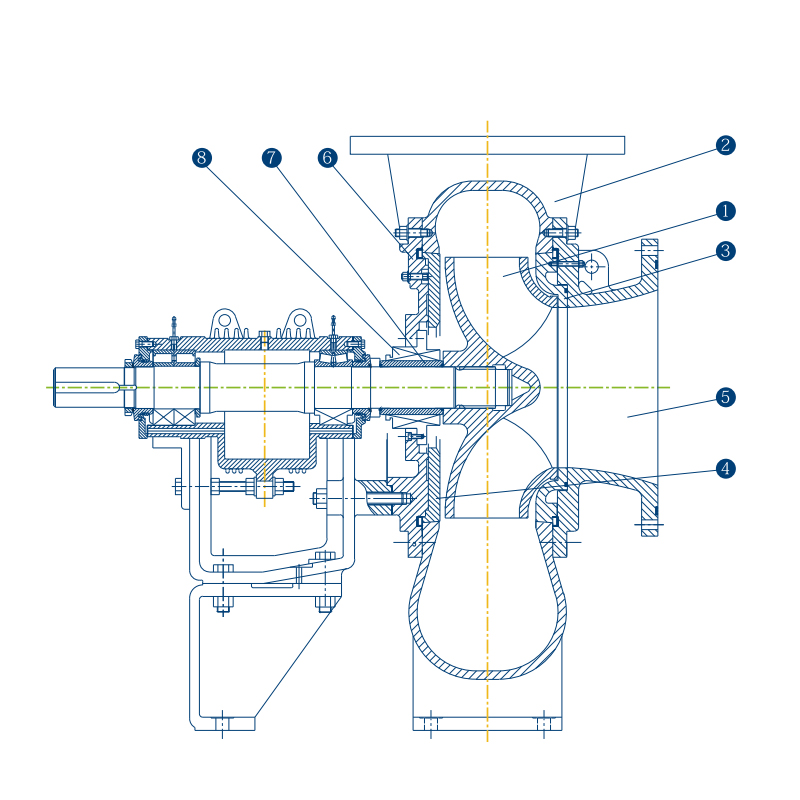

The basic working principle of an industrial slurry pump involves creating a low-pressure area to facilitate the flow of the slurry. The pump impeller, which is a rotating component, imparts kinetic energy to the slurry, allowing it to flow from the pump's inlet to the discharge outlet. The design of the impeller and the casing is critical. They must be optimized for efficient fluid dynamics, ensuring that solids move smoothly through the pump without causing blockages.

Key Features of Slurry Pumps

1. Durability Given the abrasive nature of slurries, slurry pumps are built using materials that can withstand high wear rates. High-chrome alloys or rubber linings offer longevity and reduced maintenance needs.

2. Self-Priming Many slurry pumps come with self-priming capabilities, which means they can create a vacuum to draw fluid into the pump without needing a separate priming procedure. This feature is vital in operations where slurries may intermittently be low.

industrial slurry pumps

3. Variable Speed Options The ability to adjust the speed of the pump can be beneficial. Depending on the slurry's characteristics and the specific requirements of operations, variable speed pumps can offer better control over the flow rate and pressure.

4. Versatile Design Slurry pumps are designed to handle various slurries, whether they are viscous, corrosive, or high-density. Many models are adapted for specific applications, making them versatile across different industries.

Applications in Various Industries

1. Mining In mining operations, slurry pumps transport mineral slurries, often containing large amounts of abrasive materials and varying particle sizes. Their role is crucial in processes such as ore extraction and processing.

2. Construction Slurry pumps are used to move cement slurries, mud, and other materials during various construction phases, including tunneling and piling. Their ability to transfer heavy slurries safely and efficiently is invaluable.

3. Wastewater Treatment In sewage and wastewater treatment facilities, slurry pumps manage the movement of sludge and other solids. They help maintain the flow of materials through treatment processes, ensuring efficiency and compliance with environmental standards.

4. Chemical Processing Industries that handle powdered chemicals or by-products often use slurry pumps to manage mixtures that require safe and efficient transportation.

Conclusion

Industrial slurry pumps are vital for many sectors that require the efficient handling of challenging materials. Their unique design features cater to the specific needs of various industries, ensuring safe and effective transportation of slurry mixtures. By understanding the characteristics and applications of these pumps, companies can optimize their operations, reduce maintenance costs, and improve overall productivity. As technology advances, we may see even more innovative solutions in slurry pumping, enhancing the capabilities and efficiency of these essential machines.

-

Reliable Non-Clog Sewage Pumps with GPT-4-Turbo Tech

NewsAug.04,2025

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025