English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 13, 2024 17:00 Back to list

idb35 slurry pump - vertical slurry pump

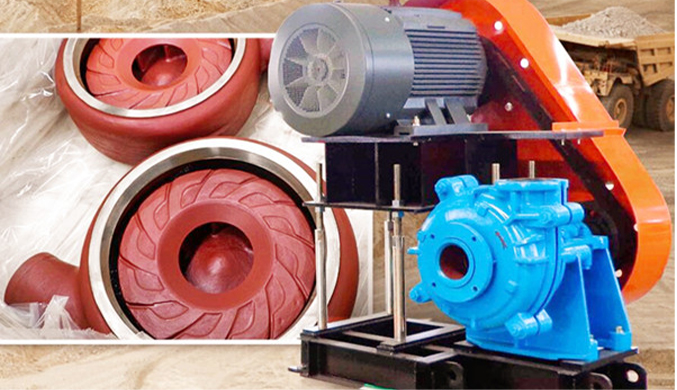

The IDB35 Slurry Pump An Overview of Vertical Slurry Pump Technology

In industrial applications, the efficiency and reliability of pumping systems play a critical role in maintaining operational productivity. Among the various types of pumps available, the IDB35 slurry pump, specifically designed as a vertical slurry pump, has garnered significant attention for its unique features and capabilities.

The IDB35 Slurry Pump An Overview of Vertical Slurry Pump Technology

The design of the IDB35 slurry pump incorporates a robust construction, typically featuring materials that can withstand the harsh conditions encountered in slurry transport. The pump is often made from high chrome alloy or rubber-lined materials, which provide excellent resistance against corrosion and abrasion, extending the lifespan of the equipment. This durability translates into reduced maintenance costs and downtime, which are crucial for industries where uptime is paramount.

idb35 slurry pump - vertical slurry pump

Performance-wise, the IDB35 pump stands out due to its high flow capacity and efficient energy consumption. It is designed to operate at optimal efficiency, allowing for the transportation of large volumes of slurry with minimal energy expenditure. This characteristic is especially beneficial in large-scale operations, where energy costs can significantly impact overall operating expenses.

Another advantage of the IDB35 vertical slurry pump is its easy integration into existing systems. It can be paired with various drive options, including electric motors and diesel engines, providing flexibility for different operational needs. Additionally, the pump is equipped with a user-friendly interface, allowing for straightforward monitoring and control, which aids in maintaining optimal performance.

However, while the IDB35 slurry pump boasts several advantages, it is essential to consider the specific requirements of each application when selecting a slurry pump. Factors such as the type of slurry being pumped, the required flow rate, and the overall system configuration will influence the performance of the pump. Consulting with experts in slurry pump technology can ensure that the most suitable pump is selected for a given application.

In conclusion, the IDB35 vertical slurry pump represents a significant advancement in slurry handling technology. Its vertical design, robust construction, and efficient performance make it an ideal choice for industries dealing with challenging slurry applications. By investing in high-quality pumps like the IDB35, companies can enhance productivity, reduce operational costs, and ensure the longevity of their pumping systems. As industries continue to evolve, the significance of reliable and efficient slurry pumps will remain paramount.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025