English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 10, 2024 05:38 Back to list

Horizontal Chemical Pipeline Centrifugal Pump for Efficient Liquid Transport Solutions

The Role of Horizontal Chemical Pipeline Centrifugal Pumps in Modern Industry

In the realm of chemical processing and transportation, the efficiency and reliability of equipment are paramount. Among the various pumping solutions available, horizontal chemical pipeline centrifugal pumps have emerged as a critical component in ensuring the smooth transfer of liquids in various industrial applications. These pumps are specifically designed to handle a wide range of chemical substances, making them indispensable in sectors such as petrochemicals, pharmaceuticals, and wastewater treatment.

Understanding Horizontal Centrifugal Pumps

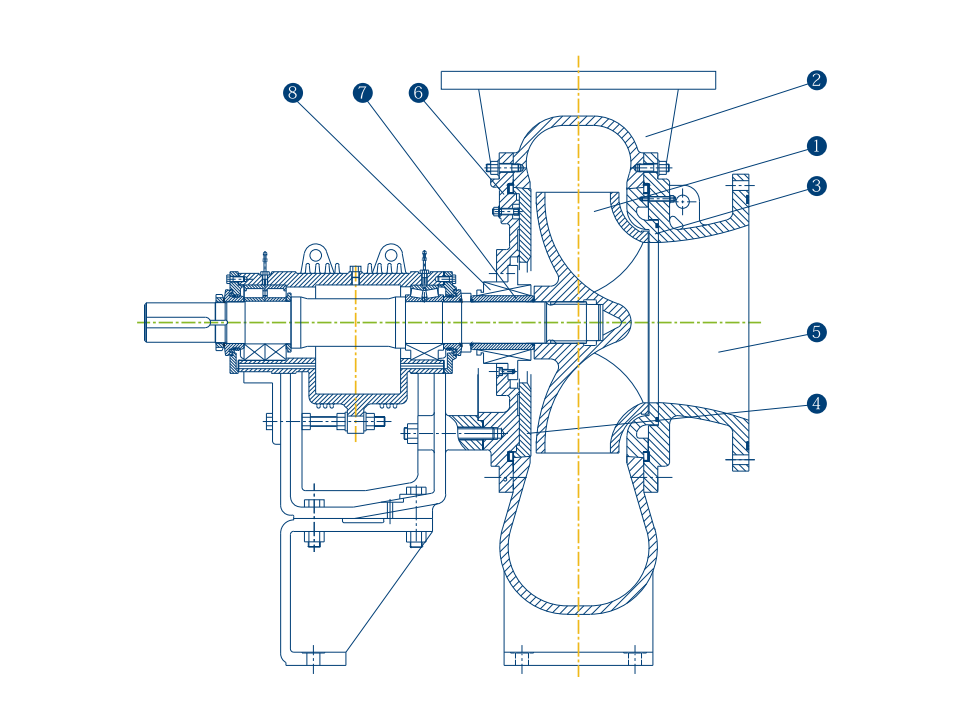

Centrifugal pumps operate on a straightforward principle they convert mechanical energy into kinetic energy, which then transforms into pressure energy, enabling the movement of fluids. A horizontal centrifugal pump features a horizontally-oriented shaft which aids in the optimal flow of chemicals across pipelines. This configuration not only simplifies the design but also facilitates easier maintenance and installation.

The critical components of horizontal centrifugal pumps include the impeller, volute casing, and motor. The impeller, rotating at high speeds, accelerates the fluid and sends it towards the volute casing, where the velocity is converted into pressure. The motor provides the necessary energy to drive the impeller, ensuring that the pump operates efficiently even under varying operational conditions.

Benefits of Horizontal Chemical Pipeline Centrifugal Pumps

One of the significant advantages of horizontal centrifugal pumps is their ability to handle a wide range of flow rates and pressures. This versatility makes them suitable for transporting different types of chemicals, including corrosive and viscous fluids. Moreover, their robust construction allows them to function effectively in demanding environments, minimizing downtime and maintenance costs.

horizontal chemical pipeline centrifugal pump

Another benefit lies in their ease of operation. With straightforward control mechanisms, these pumps can be quickly adjusted to meet the specific needs of various processes. This adaptability not only enhances operational efficiency but also ensures that the pumping system remains cost-effective.

Furthermore, horizontal centrifugal pumps are designed with safety in mind, particularly when handling hazardous substances. Many models are equipped with features such as double mechanical seals and leak detection systems, which help contain potential spills or leaks, thereby protecting workers and the environment.

Applications in Various Industries

Horizontal chemical pipeline centrifugal pumps are widely used across multiple sectors. In the petrochemical industry, they are essential for transporting crude oil and refined products between facilities. The pharmaceutical sector relies on these pumps for precise dosing of chemicals during drug manufacturing processes. Additionally, in wastewater treatment, they help in the movement of sewage and sludge, ensuring that facilities operate effectively to treat and recycle water.

Conclusion

As industries continue to evolve and demand greater efficiency in their processes, horizontal chemical pipeline centrifugal pumps will remain a vital component of chemical handling systems. Their innovative design, reliability, and capacity to manage a variety of fluids make them indispensable in modern industrial applications. With ongoing advancements in pump technology, we can expect even more robust and efficient models to emerge, further enhancing their role in safe and effective fluid transport. The importance of selecting the right pump for specific chemical processes cannot be overstated, as it directly impacts operational efficiency, safety, and environmental sustainability.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump|High Efficiency&Low Noise

NewsJul.29,2025