English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 05, 2024 16:20 Back to list

horizontal chemical pipeline centrifugal pump

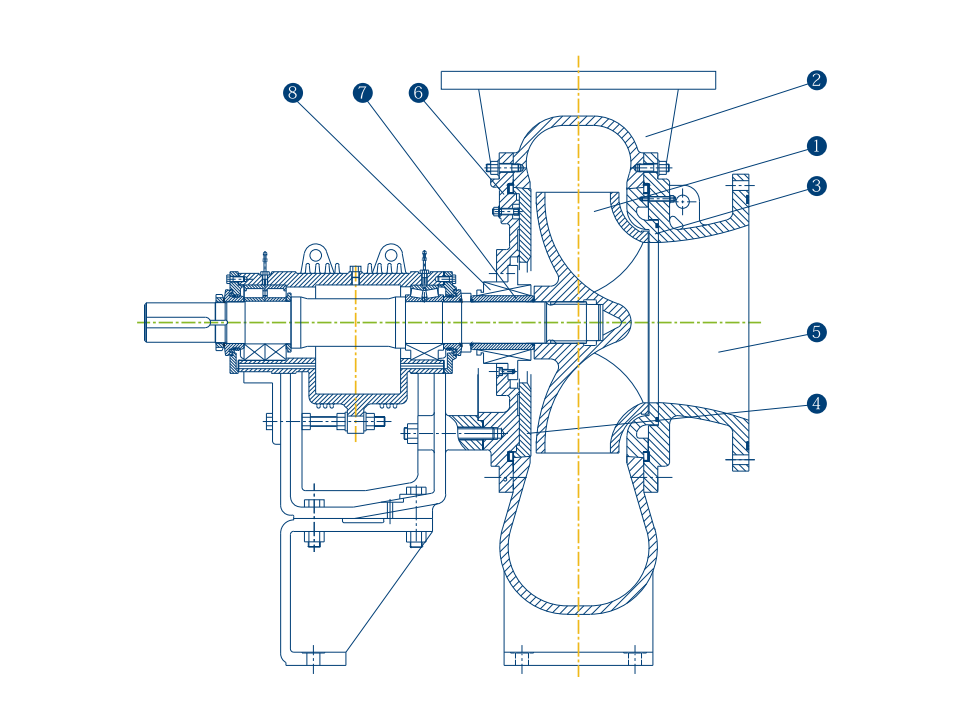

Horizontal Chemical Pipeline Centrifugal Pump An Overview

Horizontal chemical pipeline centrifugal pumps are critical components in various industries, including chemical processing, water treatment, and oil and gas

. These pumps are designed to efficiently transport fluids through pipelines, ensuring smooth operation and optimal performance in demanding environments.One of the primary advantages of horizontal centrifugal pumps is their robust design, which allows them to handle a wide range of chemical substances, including corrosive and viscous liquids. The horizontal configuration not only facilitates easy installation and maintenance but also optimizes space in industrial settings. Unlike vertical pumps, horizontal pumps have a lower center of gravity, contributing to their stability and reducing the likelihood of vibrational issues.

The operation of a horizontal centrifugal pump is based on the principle of converting mechanical energy into hydraulic energy. When the motor drives the impeller, it rotates and imparts kinetic energy to the fluid, which is then converted into pressure energy as the fluid exits through the discharge port. This design allows for a consistent flow rate and pressure, which is crucial for maintaining production efficiency in chemical processes.

horizontal chemical pipeline centrifugal pump

To ensure durability and reliability, these pumps are constructed using high-quality materials resistant to corrosion and wear. Common materials include stainless steel, duplex stainless steels, and various high-performance polymers. This selection of materials extends the pump's lifespan and minimizes maintenance costs, making it a cost-effective choice for industries dealing with aggressive chemicals.

Moreover, horizontal chemical pipeline centrifugal pumps can be equipped with various features to enhance their performance. These may include variable frequency drives (VFDs) for better flow control, mechanical seals to prevent leaks, and advanced monitoring systems for predictive maintenance. The integration of these technologies allows operators to maintain optimal pump performance while reducing energy consumption and downtime.

In conclusion, horizontal chemical pipeline centrifugal pumps are vital for the effective transport of chemicals in diverse industrial applications. Their robust construction, efficient design, and adaptability to various operating conditions make them indispensable in maintaining the flow of fluids. As industries continue to evolve and face new challenges, the importance of reliable pump technology remains paramount in ensuring consistent and safe operations. Selecting the appropriate pump for specific applications can lead to enhanced efficiency, reduced operational costs, and extended equipment life, underscoring the critical role of these pumps in modern industrial processes.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025