English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 01, 2024 02:21 Back to list

Horizontal Froth Slurry Pump Manufacturers Leading Innovations in Fluid Transport Solutions for Various Industries

Understanding Horizontal Froth Slurry Pumps A Comprehensive Guide for Manufacturers

In the realm of industrial processing, particularly within the mining and mineral processing sectors, the efficient handling of frothy slurries is critical. Horizontal froth slurry pumps have emerged as a vital component in the transportation and management of these challenging materials. This article aims to delve into the functionality, importance, and market dynamics regarding horizontal froth slurry pump manufacturers.

What is a Horizontal Froth Slurry Pump?

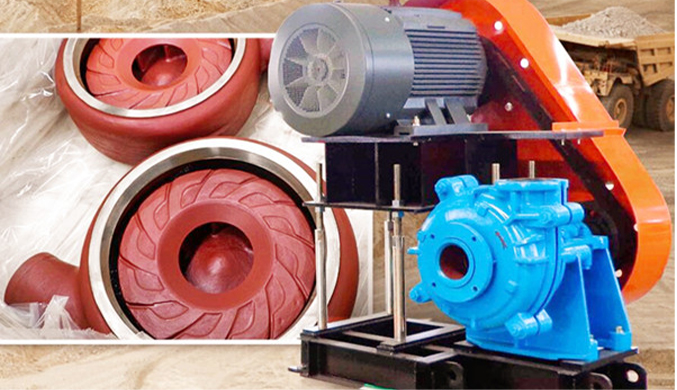

Horizontal froth slurry pumps are designed to transport mixtures of solids, liquids, and air. These pumps are particularly adept at managing frothy slurries, which are created when air becomes trapped in the liquid due to agitation or chemical reactions. The challenge with these slurries lies in their less-than-ideal flow characteristics and the potential for clogging and cavitation, which can significantly hinder operational efficiency.

These pumps operate horizontally, meaning they have a horizontal shaft with the impeller positioned parallel to the motor. This design typically allows for better accessibility and maintenance, as well as a more effective sealing system to prevent leakage. The ability to handle high concentrations of solids and the presence of air bubbles sets them apart from standard slurry pumps.

Importance in Industry

The role of horizontal froth slurry pumps is underscored in various industries—most notably mining, mineral processing, and wastewater treatment. In mining operations, these pumps facilitate the movement of ores mixed with water and air, ensuring that the extraction process is smooth and continuous. Similarly, in mineral processing, they are integral in controlling the concentration of valuable minerals while managing froth created during flotation processes.

Furthermore, in wastewater treatment facilities, horizontal froth slurry pumps are used to efficiently manage sludge and other waste byproducts, allowing for better treatment of effluents and reducing environmental impacts

. This versatility enhances their appeal and essentiality across multiple sectors.Key Features and Innovations

horizontal froth slurry pump manufacturers

Manufacturers of horizontal froth slurry pumps focus on several key features that enhance the performance and reliability of their products. These features include robust designs to withstand harsh operational environments, corrosion-resistant materials to handle abrasive slurries, and advanced sealing technologies to mitigate leakage.

Recent innovations have also seen manufacturers incorporate variable speed drives and advanced monitoring systems, allowing for enhanced control over pump operations. This adaptability is crucial in fluctuating workload situations, ensuring that the correct amount of slurry is pumped under varying conditions.

Choosing the Right Manufacturer

When selecting a horizontal froth slurry pump manufacturer, buyers should consider several factors

1. Experience and Reputation Established manufacturers often have a wealth of experience and a track record of quality products. 2. Customization The ability to offer customized solutions for specific applications can distinguish a manufacturer from its competitors.

3. Support and Service Post-purchase support, including maintenance and warranty services, is crucial for ensuring long-term operational success.

4. Quality of Materials The use of high-grade materials can significantly impact the lifespan and performance of the pumps.

5. Technological Advancements Manufacturers that invest in R&D to incorporate the latest technologies often provide superior products that are more efficient and reliable.

In conclusion, horizontal froth slurry pumps play an essential role in several industries by effectively handling frothy slurries. Manufacturers dedicated to innovation and quality will continue to shape the future of this critical equipment. As industries evolve and the demand for efficient processing increases, the importance of these pumps and their manufacturers will undoubtedly grow, underscoring their significance in the industrial landscape.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025