English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 19, 2024 12:41 Back to list

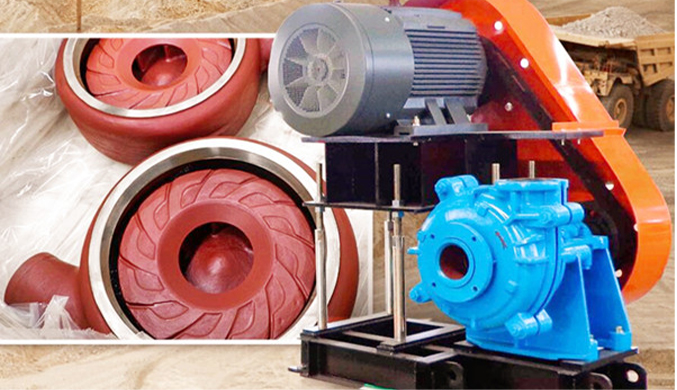

Durable OEM High-Performance Slurry Pump for Heavy-Duty Applications

High-Quality OEM High-Head Slurry Pumps A Comprehensive Overview

In the industrial sector, the efficient transport of abrasive and viscous materials is a vital requirement, particularly in sectors such as mining, construction, and wastewater management. One of the most effective solutions for this task is the high-quality OEM (Original Equipment Manufacturer) high-head slurry pumps. These specialized pumps are designed to handle slurries, which consist of a mixture of solids and liquids, delivering them at high pressures and over considerable distances.

Understanding High-Head Slurry Pumps

High-head slurry pumps are engineered specifically to manage high delivery head requirements, making them ideal for applications where materials need to be transported upwards or across long distances. Unlike standard pumps, high-head models feature robust construction and unique design elements that allow them to withstand the abrasive nature of slurries, which often contain hard particles like sand, gravel, or minerals.

The term OEM signifies that these pumps are manufactured to meet the specifications of a particular brand or industry standard. This ensures that the pumps not only perform reliably but also integrate seamlessly with existing systems, enhancing overall operational efficiency.

Key Features of High-Quality OEM High-Head Slurry Pumps

1. Durability and Longevity High-quality slurry pumps are typically constructed from materials such as high-chrome alloys, which are resistant to wear and corrosion. This makes them capable of enduring harsh working environments, thereby reducing maintenance costs and downtime.

2. High Efficiency These pumps are designed for optimal hydraulic performance. Advanced hydraulic modeling techniques are used during design to ensure maximum flow rates and minimal energy consumption. This efficiency is critical in applications where energy costs represent a significant portion of operational expenses.

3. Versatility High-head slurry pumps can be utilized in various industries, including mining, coal handling, steel manufacturing, and the treatment of wastewater. They are adaptable to various slurry compositions, including those with different solid sizes and concentrations.

4. Customizable Designs OEM pumps can be specifically tailored to the needs of individual clients, ensuring that they meet particular operational requirements. Custom designs may include variations in impeller size, casing configuration, and material selection based on the nature of the slurry being pumped.

high quality oem high head slurry pump

5. Advanced Technology Many OEM manufacturers utilize cutting-edge technology in their pump designs. This includes computational fluid dynamics (CFD) modeling to optimize performance and durability. Advanced sealing technologies also help minimize leakage, thereby improving safety and efficiency.

Applications of High-Head Slurry Pumps

High-head slurry pumps are crucial in several applications. In mining, for example, they transport tailings and slurry from the extraction site to processing plants. In coal handling, they efficiently move coal-water slurries for processing. Wastewater treatment facilities rely on these pumps for the removal of sludge and other solids during treatment processes.

Additionally, the construction industry employs high-head slurry pumps in applications such as dewatering and the transportation of cement slurries during the mixing and pouring of concrete.

Choosing the Right OEM High-Head Slurry Pump

When selecting a high-head slurry pump, it's essential to consider several factors

- Slurry Characteristics Understand the properties of the slurry, including its density, viscosity, and abrasive nature, to select the appropriate pump material and design. - Flow and Head Requirements Determine the necessary flow rate and the height to which the slurry needs to be pumped. - System Compatibility Ensure that the pump integrates well with existing systems, taking into account factors such as connection sizes and piping configurations. - Manufacturers' Reputation Choose OEM pumps from reputable manufacturers known for their quality, innovation, and support services.

Conclusion

High-quality OEM high-head slurry pumps are an indispensable component in various industrial applications. Their ability to efficiently transport challenging materials, coupled with their durability and customization options, makes them a preferred choice for industries dealing with slurries. By investing in the right pump solutions, businesses can enhance productivity, reduce operational costs, and ensure the smooth functioning of their processes. As technology continues to advance, the capabilities of these pumps will likely expand, further improving their effectiveness in handling slurry transportation challenges.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025