English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dec . 06, 2024 14:45 Back to list

'hart slurry pumps efficiently handle abrasive fluids.'

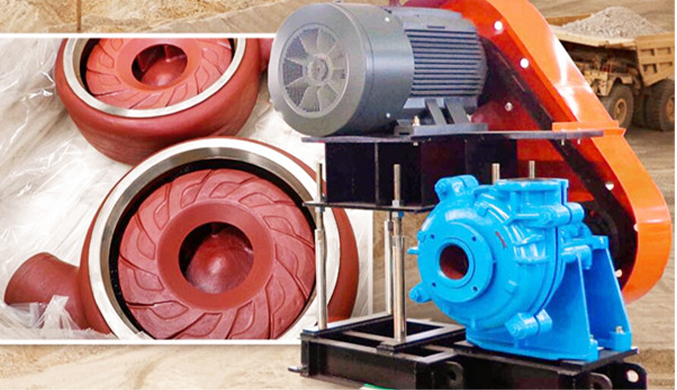

Efficient Handling of Abrasive Fluids with Hart Slurry Pumps

In industries that involve the transportation of abrasive fluids, the choice of pumping equipment is critical to ensuring both operational efficiency and cost-effectiveness. Hart slurry pumps have emerged as a trusted solution for handling these challenging materials. With their innovative design and robust construction, these pumps are engineered to thrive in demanding environments, making them a preferred choice for various applications across multiple sectors.

Understanding Abrasive Fluids

Abrasive fluids are mixtures that contain solid particles, which can cause wear and tear on traditional pumping equipment. Common examples include slurries found in mining operations, wastewater treatment, and construction sites. The nature of these fluids poses significant challenges, including higher maintenance costs, reduced operational lifetimes of pumps, and the potential for frequent breakdowns. Therefore, selecting the right pump is essential to minimize downtime and maintenance, ultimately improving the bottom line.

The Design of Hart Slurry Pumps

Hart slurry pumps are specifically designed to tackle the complexities associated with abrasive fluids. Their robust construction typically involves high-chrome cast iron or specialized materials that resist corrosion and wear, ensuring longevity even in the harshest environments. Moreover, the pumps feature a unique impeller design that optimizes flow dynamics, allowing for efficient handling of thick, viscous slurries.

One notable feature of Hart slurry pumps is their ability to manage high solid content without compromising performance. This is crucial in applications where solid particles can account for a substantial portion of the fluid. The pump's hydraulic design facilitates a smooth and continuous flow, reducing the risk of blockages and ensuring that operations remain uninterrupted.

Operational Efficiency

'hart slurry pumps efficiently handle abrasive fluids.'

Another compelling advantage of Hart slurry pumps is their energy efficiency. The pumps are engineered to operate with minimal energy consumption, which is increasingly important in today’s cost-conscious industrial landscape. By reducing energy costs, facilities not only save money but also contribute to environmental sustainability—a goal that is becoming increasingly prioritized across industries.

Easy Maintenance

Maintenance is often cited as one of the most significant concerns in pump operation. Hart slurry pumps address this by incorporating design features that simplify maintenance processes. For instance, many models allow for easy access to critical components, enabling operators to conduct inspections, replacements, and repairs without extensive downtime. This ease of maintenance significantly reduces operational disruptions and enhances overall productivity.

Versatility Across Industries

Hart slurry pumps are utilized in a variety of sectors, including mining, metallurgy, and chemical processing. In mining, they transport slurries from processing plants to tailings storage facilities, efficiently managing the heavy loads associated with mineral extraction. In wastewater treatment, they deal with the transport of sludge, ensuring that facilities can maintain optimal functioning with minimal disturbance. The chemical industry also benefits from these pumps, where they can handle corrosive slurries while maintaining operational integrity.

Conclusion

In conclusion, Hart slurry pumps stand out as a highly effective solution for industries managing abrasive fluids. Their durable construction, energy-efficient operation, and user-friendly maintenance features make them a cost-effective choice for businesses aiming to enhance efficiency and reduce downtime. As industries continue to face the challenges associated with abrasive materials, the role of reliable and efficient pumping solutions like Hart slurry pumps becomes increasingly vital. By investing in these advanced pumping systems, companies can ensure they are better equipped to handle the demands of their operations while safeguarding their bottom line.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump|High Efficiency&Low Noise

NewsJul.29,2025