English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 15, 2024 12:01 Back to list

Exploring the Efficiency and Applications of Centrifugal Slurry Pumps in Various Industries

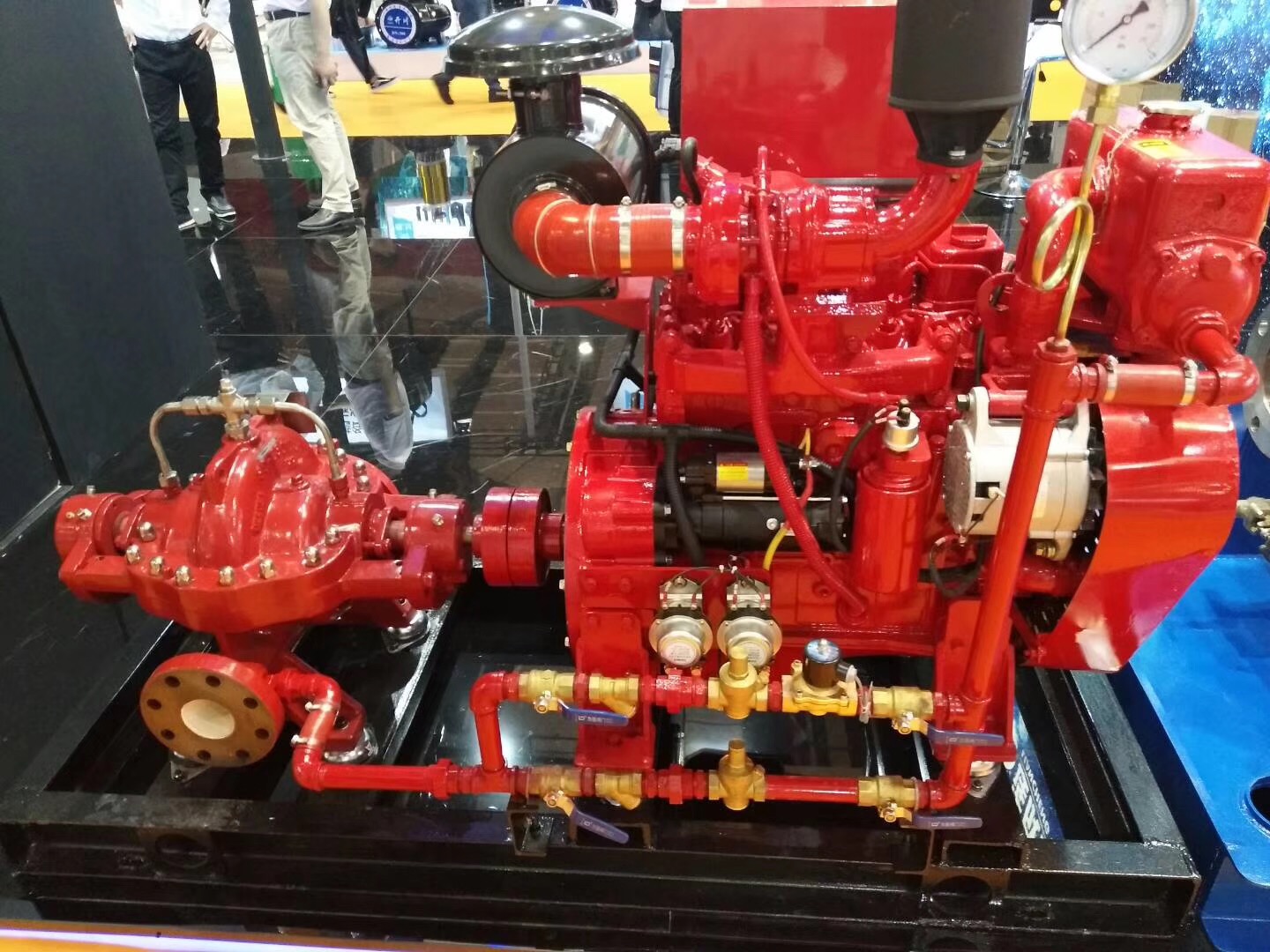

Understanding Slurry Pumps A Focus on Centrifugal Technology

In various industries such as mining, construction, and wastewater management, the need to transport abrasive and viscous materials has led to the development of specialized equipment—among which slurry pumps have gained significant importance. Among the different types, centrifugal slurry pumps are particularly popular due to their effectiveness in handling tough applications. This article delves into the function, design, advantages, and applications of centrifugal slurry pumps.

What is a Slurry Pump?

A slurry pump is a type of pump designed to transport a mixture of liquid with solid particles, known as slurry. Slurries can be composed of various materials, including minerals, aggregates, or even organic matter, which makes them vital in industries that deal with such mixtures. Unlike regular pumps that are typically used to transfer clear liquids, slurry pumps need to be engineered to handle abrasive wear and high solids content without compromising efficiency.

The Mechanism of Centrifugal Slurry Pumps

Centrifugal slurry pumps operate on the principle of converting rotational kinetic energy, typically from a motor, into hydrodynamic energy. The core components of these pumps include an impeller, a casing, and a shaft. As the impeller spins, it accelerates the slurry outward from the center, generating centrifugal force. This force pushes the mixture into the casing and forces it out through the discharge outlet. The design of the impeller and casing is crucial as it directly affects the pump's ability to handle slurries with varying viscosities and particle sizes.

Advantages of Centrifugal Slurry Pumps

1. Efficiency One of the primary advantages of centrifugal slurry pumps is their high efficiency in transporting slurries over long distances. The centrifugal action ensures a continuous flow, reducing the likelihood of blockages.

slurry pump centrifugal

2. Simple Design The design of centrifugal pumps is relatively simple, making them easy to maintain and repair. This simplicity also contributes to their reliability and durability in challenging operating conditions.

3. Versatility Centrifugal slurry pumps can be tailored for various applications, with options for different materials and configurations. Whether it’s handling coarse particles in mining or fine particles in wastewater treatment, these pumps can be adapted to serve specific needs.

4. Cost-Effectiveness While the initial investment in centrifugal slurry pumps may be higher than that of standard pumps, their efficiency and lower maintenance costs often make them more economical in the long run.

Applications of Centrifugal Slurry Pumps

Centrifugal slurry pumps find applications in numerous sectors. In the mining industry, they are essential for transporting slurries containing ore, tailings, and other materials. In construction, they can handle cement slurries and mixtures used in various processes. Furthermore, in wastewater treatment, these pumps are crucial for transporting sludge and waste materials through the treatment processes.

Conclusion

Centrifugal slurry pumps are indispensable tools in many industrial processes that require the efficient and reliable transportation of slurries. Their unique design, combined with their operational efficiency and versatility, makes them suitable for a wide range of applications, from mining to wastewater treatment. As industries continue to evolve, the role of these pumps will likely expand, underscoring their significance in modern industrial operations. Understanding the workings and benefits of centrifugal slurry pumps is essential for professionals in these sectors seeking to optimize their processes and enhance productivity.

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025