English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 16, 2024 14:55 Back to list

Essential Components for Slurry Pump Maintenance and Performance Optimization

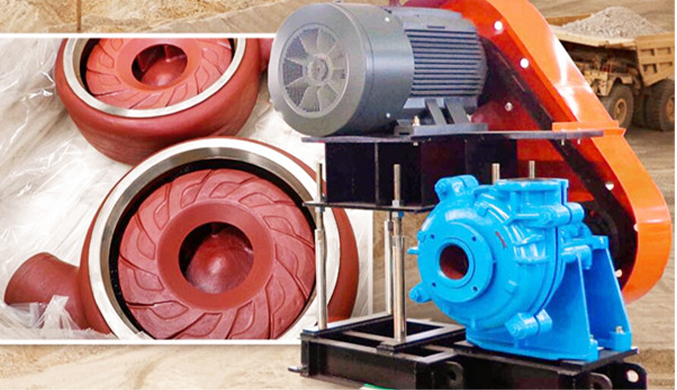

Understanding Slurry Pump Spares A Comprehensive Guide

Slurry pumps are essential machinery in various industries, including mining, chemical processing, and construction. These pumps are designed to handle abrasive and viscous materials, often transporting slurries consisting of a mixture of solids and liquids. Given their demanding working conditions, slurry pumps experience significant wear and tear, resulting in the need for timely replacement of spare parts. This article provides an overview of slurry pump spares, their importance, types, and the factors to consider when selecting replacement parts.

Importance of Slurry Pump Spares

The longevity and efficiency of slurry pumps largely depend on the quality and availability of their spare parts. Using appropriate spares ensures that the pump operates at optimal performance, minimizing downtime and maintenance costs. Over time, components of slurry pumps such as impellers, liners, and shafts can become worn out, leading to reduced efficiency, increased energy consumption, and potential breakdowns. Therefore, having a reliable stock of spare parts is crucial for smooth operations.

Types of Slurry Pump Spares

1. Impellers The heart of the slurry pump, impellers are responsible for transferring energy to the slurry. They are prone to wear, especially when handling abrasive materials. Depending on the application, impellers come in various designs, such as open, semi-open, and closed types, each providing different hydraulic characteristics.

2. Liners Liner materials protect the pump casing from wear and erosion caused by solid particles in the slurry. Liners can be made from various materials, including rubber, polyurethane, and metal, each offering different levels of abrasion resistance and durability.

3. Shafts The shafts connect the impeller to the motor and transmit the rotational energy needed for pumping. They must be strong enough to withstand high torque and wear from the slurry. Choosing the right shaft material and design is crucial for effective performance.

4. Seals and Bearings Seals are essential for preventing leaks of the slurry, while bearings support the rotating elements of the pump. Replacing worn-out seals and bearings is vital to avoid contamination and maintain operational efficiency.

slurry pump spares

5. Gaskets and O-rings These components ensure proper sealing between different parts of the pump, preventing leaks and maintaining pressure. Over time, they can degrade, leading to fluid loss and decreased efficiency.

Factors to Consider When Selecting Slurry Pump Spares

1. Compatibility Ensure that the spare parts are compatible with the specific make and model of your slurry pump. Using non-compatible parts can lead to operational issues and safety hazards.

2. Material Selection The material of the spare parts should match the type of slurry being handled. For example, highly abrasive slurries may require spares made from materials with superior wear resistance.

3. Quality Opt for high-quality spare parts from reputable manufacturers. While cheaper options may seem appealing, they can lead to increased maintenance costs and pump downtime in the long run.

4. Lead Time Consider the lead time for obtaining spare parts. Delays in sourcing critical components can result in prolonged downtime, negatively impacting productivity.

5. Supplier Reputation Choose suppliers with a good reputation in the industry. Reliable suppliers can provide not only high-quality parts but also valuable technical support and advice on maintenance practices.

Conclusion

In conclusion, slurry pump spares are vital for ensuring the efficiency and longevity of slurry pump operations. Understanding the different types of spares and the factors affecting their selection can help businesses minimize downtime and enhance productivity. Investing in quality spare parts and maintaining a well-stocked inventory will ultimately lead to more reliable and efficient slurry handling processes.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Conservation, Low Noise

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy-Saving

NewsJul.29,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD. | High Efficiency, Energy-Saving

NewsJul.29,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsJul.29,2025

-

High-Efficiency Vertical Slurry Pumps for Mining & Industry Solutions

NewsJul.29,2025

-

High-Efficiency Pipeline Pump Solutions for Every Pipeline Pump Station

NewsJul.29,2025