English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 29, 2024 03:40 Back to list

Understanding the Functionality and Applications of Ejector Pumps in Various Industries

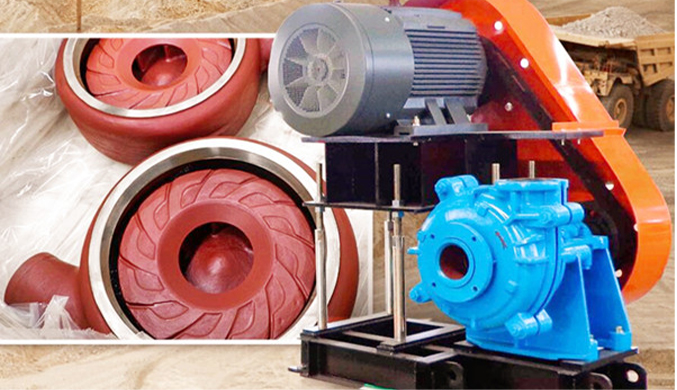

Ejector pumps, also known as ejector systems or jet pumps, are a vital component in various industries, providing an efficient solution for transferring liquids, slurries, and gases. These devices utilize the principles of fluid dynamics to create a suction effect, allowing them to draw fluids from one location to another without the need for moving parts, making them a reliable choice for many applications.

The design of an ejector pump usually involves a nozzle, a mixing chamber, and a diffuser. When high-pressure fluid is directed through the nozzle, it creates a low-pressure area in the mixing chamber. This low pressure allows surrounding fluids to be sucked into the chamber, where they mix with the high-pressure fluid and are then expelled through the diffuser. This process not only enables the pump to move liquids but also allows it to handle solid particles and other challenging materials.

Ejector pumps are particularly advantageous in situations where electrical power sources are limited or where a flame-proof solution is necessary. For instance, in wastewater management, ejector pumps are employed to transport sewage and sludge from lower to higher elevations, effectively moving waste to treatment facilities. In industries such as mining, they help in the dewatering of pits and processing areas, improving operational efficiency.

ejector pumps

Another significant benefit of ejector pumps is their maintenance-free operation due to the lack of mechanical components

. This reduces operational costs and downtime, making them an attractive option for manufacturers and service providers. Additionally, they can be designed to work with various media, including corrosive fluids, making them versatile for different environments.However, it’s important to select the right ejector pump for specific applications, as factors such as fluid viscosity, temperature, and the nature of the materials being pumped can affect performance. Proper sizing and configuration can optimize the pump's effectiveness, ensuring that it meets the specific demands of the application.

In summary, ejector pumps are essential tools in fluid transfer, offering a reliable, maintenance-free, and versatile solution across various industries. Their unique operating principles and design make them suitable for handling a wide range of materials and conditions, ultimately enhancing operational efficiency while reducing costs.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025