English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 21, 2024 11:33 Back to list

Effective Techniques for Pumping and Handling Slurries in Various Industries

Understanding Pumping Slurries Key Concepts and Applications

Pumping slurries is an essential process across various industries, notably in mining, chemical manufacturing, and wastewater treatment. A slurry is a mixture of solid particles suspended in a liquid, typically water, and is characterized by its viscosity and density. The effective transport of slurries is crucial for operational efficiency and the management of materials, making the understanding of pumping techniques and systems fundamental for engineers and practitioners in the field.

The Nature of Slurries

Slurries can vary significantly in composition, concentration, and behavior. They can be classified as thick or thin based on the ratio of solid to liquid. Thick slurries tend to be more viscous, often making them more challenging to pump. The rheological properties of a slurry, including its shear stress and viscosity, play a critical role in determining how it is handled and transported. Understanding these properties is vital for selecting the appropriate pumping equipment and ensuring optimal performance.

Pumping Mechanisms

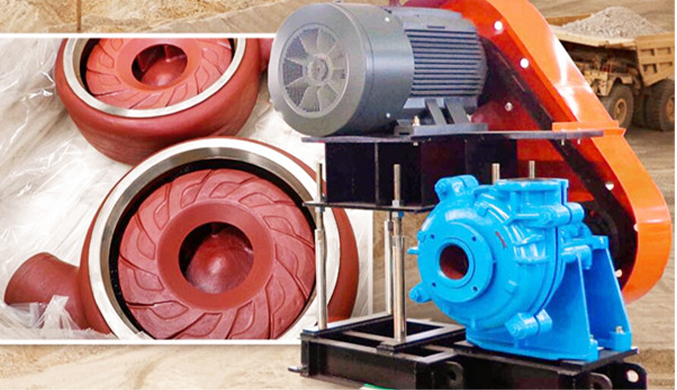

There are several types of pumps used to move slurries, including centrifugal pumps, positive displacement pumps, and screw pumps. Each type has its advantages and limitations depending on the specific application and the characteristics of the slurry being pumped.

1. Centrifugal Pumps These are commonly used for low to medium viscosity slurries. They work by converting rotational kinetic energy into hydrodynamic energy. However, centrifugal pumps may struggle with high-viscosity slurries or those with a large particle size, leading to inefficiencies or damage.

2. Positive Displacement Pumps These pumps are better suited for high-viscosity slurries. They operate by trapping a fixed amount of slurry and forcing it into the discharge pipe, providing a consistent flow regardless of the system pressure.

3. Screw Pumps These are another option for moving thick slurries and blend features from both centrifugal and positive displacement pumps. They can handle larger solid particles and have a continuously variable flow rate.

pumping slurries

Challenges in Pumping Slurries

Pumping slurries poses several challenges, primarily related to wear and clogging. The solid particles in the slurry can cause erosion and deterioration of pumping equipment over time. Material selection for pump components is therefore critical; many pumps are constructed using hard materials or lined with rubber or ceramics to resist wear.

Clogging is another significant issue that can arise, particularly with slurries that contain larger particles. To mitigate this, proper design of the piping system, including adequate pipe diameter and appropriate bends, is vital. Implementing regular maintenance schedules can ensure efficiency and longevity of the pumping systems.

Applications of Pumping Slurries

In mining, pumping slurries is integral to transporting ore from the extraction site to processing plants. The slurry form reduces the chances of material loss and simplifies the transport over long distances.

In the chemical industry, slurries are often involved in reactions and must be pumped to various stages of production with precision and care. Wastewater treatment facilities also rely heavily on slurry pumping to manage sedimentation processes and the transportation of sludge.

Conclusion

Pumping slurries is a complex but critical aspect of many industrial processes. The choice of the appropriate pump, understanding the composition of the slurry, and being aware of the challenges associated with pumping can lead to improved efficiency and reduced operational costs. As technology advances, innovative solutions continue to emerge, ensuring that the challenges of pumping slurries are met with effective strategies for successful and sustainable operations.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025