TEL:

+86 13120555503

English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Feb . 12, 2025 09:14 Back to list

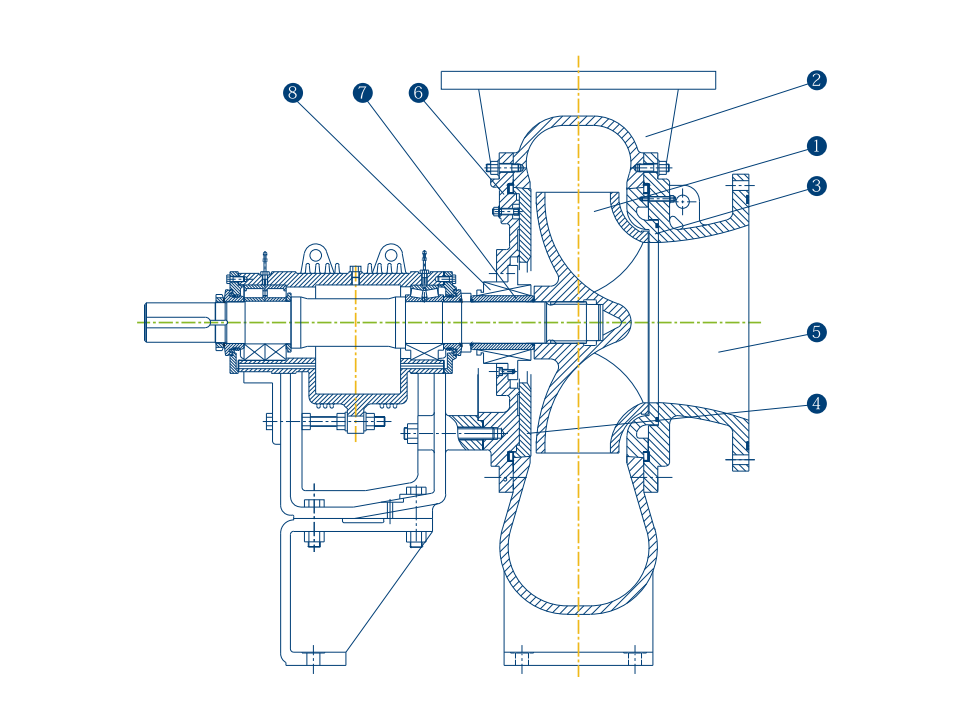

double suction horizontal split case pump

For professionals navigating the modern industrial landscape, choosing the right equipment is a task of paramount importance. Amongst various machinery, the double suction centrifugal pump stands out due to its exceptional operational efficiency and widespread utility. As industries constantly seek to optimize performance and minimize energy consumption, understanding the nuances of these pumps becomes crucial.

Authoritativeness in Application and Performance Double suction centrifugal pumps are recognized for their authority in high-volume applications. Industries rely on their robust performance credentials, particularly in environments requiring rapid and significant fluid transfer. This is supported by industry-specific certifications and compliance standards, such as ANSI and ISO, that validate their operational integrity. These standards ensure the pumps meet rigorous industry requirements for safety and efficiency. Experts in fluid dynamics endorse these pumps for their ability to maintain consistent pressure levels across extensive piping networks. Such reliability is crucial in preventing service interruptions and maintaining operational consistency, further reinforcing their authoritative status in the market. Trustworthiness Rooted in Proven Performance The trustworthiness of double suction centrifugal pumps is unequivocally established through their track record of delivering reliable service in demanding conditions over prolonged periods. This is further evidenced by the multitude of positive reviews and case studies conducted by third-party testing laboratories. End-users frequently report satisfaction with the pump’s longevity and performance stability, underscoring the return on investment it provides. As testimony to their robustness, these pumps are often installed in mission-critical applications where downtime is not an option, reflecting the trust industries place in their dependability. In conclusion, the double suction centrifugal pump emerges as a pivotal component in industrial operations, characterized by its efficiency and reliability. With an understanding grounded in experience and expertise, supported by authoritative standards and a strong reputation for trustworthiness, these pumps continue to serve as vital solutions in the pursuit of operational excellence.

Authoritativeness in Application and Performance Double suction centrifugal pumps are recognized for their authority in high-volume applications. Industries rely on their robust performance credentials, particularly in environments requiring rapid and significant fluid transfer. This is supported by industry-specific certifications and compliance standards, such as ANSI and ISO, that validate their operational integrity. These standards ensure the pumps meet rigorous industry requirements for safety and efficiency. Experts in fluid dynamics endorse these pumps for their ability to maintain consistent pressure levels across extensive piping networks. Such reliability is crucial in preventing service interruptions and maintaining operational consistency, further reinforcing their authoritative status in the market. Trustworthiness Rooted in Proven Performance The trustworthiness of double suction centrifugal pumps is unequivocally established through their track record of delivering reliable service in demanding conditions over prolonged periods. This is further evidenced by the multitude of positive reviews and case studies conducted by third-party testing laboratories. End-users frequently report satisfaction with the pump’s longevity and performance stability, underscoring the return on investment it provides. As testimony to their robustness, these pumps are often installed in mission-critical applications where downtime is not an option, reflecting the trust industries place in their dependability. In conclusion, the double suction centrifugal pump emerges as a pivotal component in industrial operations, characterized by its efficiency and reliability. With an understanding grounded in experience and expertise, supported by authoritative standards and a strong reputation for trustworthiness, these pumps continue to serve as vital solutions in the pursuit of operational excellence.

Share

Latest news

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025