English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Aug . 14, 2024 00:08 Back to list

Design and Efficiency Analysis of Double Suction Volute Pumps for Enhanced Fluid Handling Systems

Double Suction Volute Pump Efficiency and Design

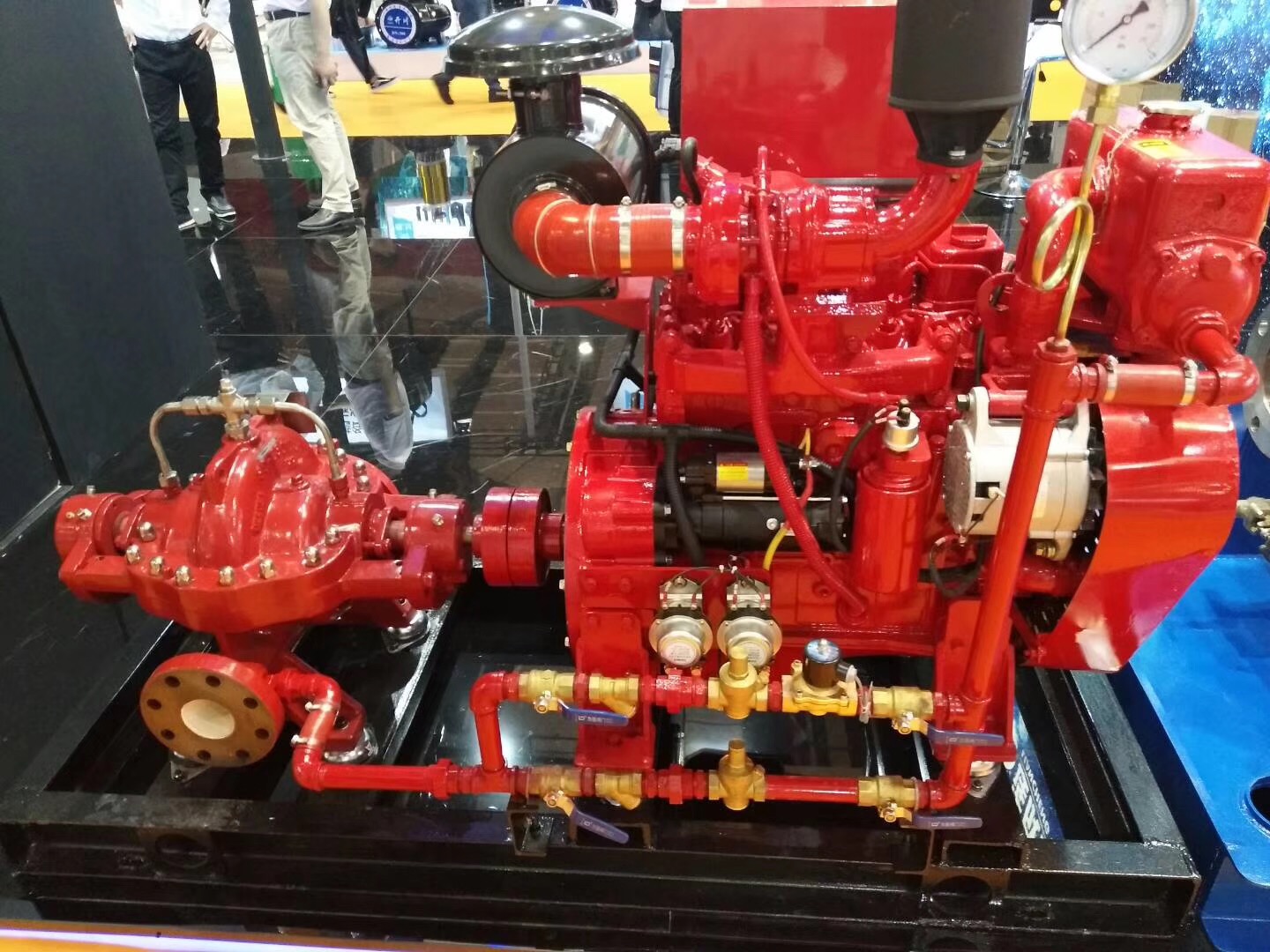

In the world of fluid dynamics, the double suction volute pump stands out as a reliable and efficient solution for transporting liquids across various industries. Known for its unique design and operational advantages, the double suction volute pump is frequently utilized in applications such as water supply, sewage treatment, and industrial processes.

Design Characteristics

The defining feature of a double suction volute pump is its dual inlet design, which allows fluid to enter from both sides of the impeller. This setup not only balances the axial thrust that can lead to wear on the bearings but also enhances the overall efficiency of the pump. The symmetrical configuration of the double suction design mitigates the risk of cavitation, ensuring prolonged functionality and less maintenance downtime.

Moreover, the volute casing plays a crucial role in the pump's operation. It is designed to convert the kinetic energy generated by the impeller into pressure energy. The volute’s gradual expansion allows for a smooth transition of flow, reducing turbulence and energy losses within the system. This design characteristic is imperative for applications that require consistent performance over extended operational periods.

Operational Efficiency

One of the primary advantages of double suction volute pumps is their high hydraulic efficiency. The dual suction entrance enables a higher flow rate and pressure output compared to single suction pumps of comparable size. This feature is particularly beneficial in large-scale applications where volume and pressure demands are significant. For instance, in municipal water supply systems, these pumps can efficiently handle large quantities of water, maintaining optimal performance and reliability.

double suction volute pump

Additionally, the even distribution of flow across the impeller blades minimizes wear and tear, leading to an extended operational lifespan. The lower maintenance requirements translate to reduced operational costs, making double suction volute pumps a cost-effective solution in the long run.

Versatility and Applications

Double suction volute pumps are versatile and can be utilized in various sectors, including agriculture, mining, and chemical processing. Their ability to operate efficiently under varying conditions makes them suitable for diverse applications. For example, in irrigation systems, they are often employed to deliver water from reservoirs to fields efficiently.

In the industrial sector, these pumps are increasingly used in cooling systems, where they help circulate water to maintain optimal temperatures in manufacturing processes. Additionally, in sewage and wastewater treatment facilities, their robust design allows them to handle solids and liquids effectively, ensuring reliable operation in challenging environments.

Conclusion

The double suction volute pump represents a significant advancement in pumping technology, successfully balancing efficiency, reliability, and longevity. Its innovative design and versatile applications have made it a preferred choice in numerous industries. As the demand for efficient fluid transfer solutions continues to grow, the double suction volute pump will likely maintain its position as a critical component in modern industrial operations. The combination of technological advancements and design improvements will undoubtedly enhance its performance further, making it an essential asset in the continuous quest for efficiency in fluid dynamics.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025