English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dec . 13, 2024 02:16 Back to list

clean water double suction pump factories

Clean Water Double Suction Pump Factories Innovating for a Sustainable Future

In an era where clean water is becoming an increasingly vital resource, the manufacturing industry is stepping up to meet the demand through innovative solutions. Among these solutions, double suction pumps have emerged as a key player in the efficient movement of clean water. Factories specializing in these pumps are at the forefront of technology, sustainability, and performance, making significant contributions to water management systems across the globe.

Understanding Double Suction Pumps

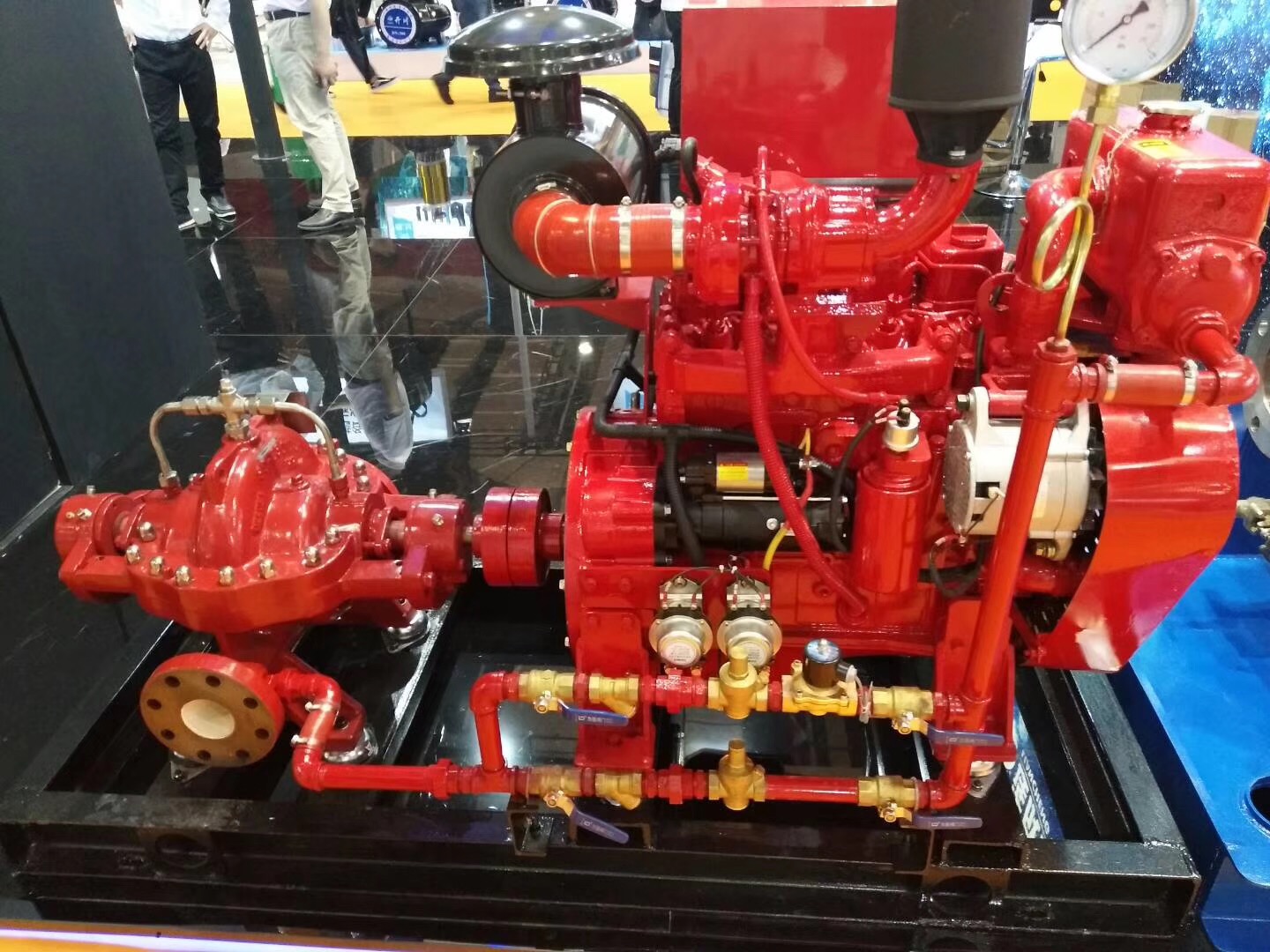

Double suction pumps are designed to handle large volumes of clean water with minimal energy consumption. Unlike traditional single-suction pumps, which draw water in from one side, double suction pumps have an inlet on both sides of the impeller. This symmetric design allows for a more balanced operation, reducing vibrations and extending the lifespan of the pump. These pumps are particularly effective in water treatment facilities, irrigation systems, and municipal water supply operations.

The Role of Factories in Innovation

Factories dedicated to the production of clean water double suction pumps play a critical role in research and development. Continuous investment in advanced technologies such as computational fluid dynamics (CFD) modeling and materials science ensures that these pumps meet the highest efficiency and performance standards. This innovation not only enhances the operational capacity of water systems but also contributes to energy saving and reduced operational costs.

Modern manufacturing practices in these factories also emphasize sustainability. Many factories are adopting environmentally friendly materials and processes, reducing waste and lowering their carbon footprints. This commitment to eco-friendly operations is essential as the global community increasingly prioritizes sustainable practices in every industry, especially those that deal with vital resources such as water.

clean water double suction pump factories

Quality Control and Standards

One of the defining features of clean water double suction pump factories is their rigorous quality control measures. To ensure that each pump meets international standards, factories run extensive testing protocols. This includes evaluating the efficiency of the pump, assessing its durability under various operating conditions, and ensuring compliance with safety regulations. By adhering to these standards, manufacturers not only guarantee the reliability of their products but also foster consumer trust in their brand.

Moreover, certification from recognized global standards organizations plays a crucial role in solidifying the reputation of these factories. ISO certifications, for example, indicate that a factory adheres to strict quality management principles, further enhancing its credibility in the market.

The Future of Water Management

As the global population continues to rise and climate patterns shift, the demand for efficient water management solutions is set to increase. Clean water double suction pump factories are positioned to be at the heart of this trend. Their commitment to innovation, quality, and sustainability will drive the evolution of water systems that can meet tomorrow's challenges.

In conclusion, clean water double suction pump factories are integral to ensuring the availability and quality of one of our most precious resources. Through advanced technology, sustainable practices, and strict quality control, these manufacturers contribute significantly to the efficiency of clean water distribution systems. As they continue to innovate, the impact of their work will resonate far beyond the walls of their factories, benefiting communities and ecosystems worldwide. The future of clean water management lies in their hands, and with it, the promise of a sustainable and equitable water supply for generations to come.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025