English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Oct . 18, 2024 01:10 Back to list

Innovative Solutions for Efficient Chemical Processing Pump Systems and Applications

Understanding Chemical Processing Pumps Selection, Features, and Applications

Chemical processing pumps are integral components in industries dealing with various chemicals, such as petrochemicals, pharmaceuticals, food processing, and wastewater management. These pumps are specifically designed to handle the unique challenges posed by corrosive, viscous, and often hazardous fluids. In this article, we will explore the significance of chemical processing pumps, their selection criteria, key features, and versatile applications.

Importance of Chemical Processing Pumps

In chemical manufacturing, reliable fluid transfer is paramount. Chemical processing pumps facilitate the movement of liquids through pipelines and systems, ensuring that production processes run smoothly. The correct pump type enhances efficiency, reduces downtime, and ensures safety in operations. Furthermore, improper pump selection can lead to costly leaks, spills, and even catastrophic failures, making the choice of pump a critical aspect of chemical processing.

Types of Chemical Processing Pumps

Chemical processing pumps can be broadly classified into two main categories positive displacement pumps and centrifugal pumps.

1. Positive Displacement Pumps These pumps move fluid by trapping a fixed amount of liquid and forcing it into the discharge pipe. They are ideal for applications requiring high viscosity fluids or when a constant flow rate is necessary. Common sub-types include gear pumps, diaphragm pumps, and progressive cavity pumps. Each of these designs offers unique advantages depending on the nature of the fluid being processed.

2. Centrifugal Pumps These pumps use rotational energy to transfer fluid by converting kinetic energy into hydrodynamic energy. Centrifugal pumps are widely used for low-viscosity fluids and are known for their efficiency and ability to handle larger volumes. However, they may not perform well with highly viscous or shear-sensitive materials.

Selection Criteria

When selecting a chemical processing pump, several factors must be considered

- Chemical Compatibility It's crucial to ensure that the materials of construction are compatible with the fluid being pumped. Corrosive substances may require special alloys or coatings to prevent deterioration.

- Viscosity of Fluids The viscosity of the chemical being transferred will affect pump performance. Some pumps are better suited for high-viscosity fluids, while others work best with low-viscosity liquids.

- Flow Rate and Pressure Requirements Understanding the required flow rate and discharge pressure is essential for choosing a pump that can meet operational demands without overworking.

- Temperature Considerations The operational temperature range of the pump materials must be considered, particularly for high-temperature processes

.- Maintenance and Reliability Choosing pumps that require minimal maintenance or have easily accessible components can lead to cost savings and increased uptime.

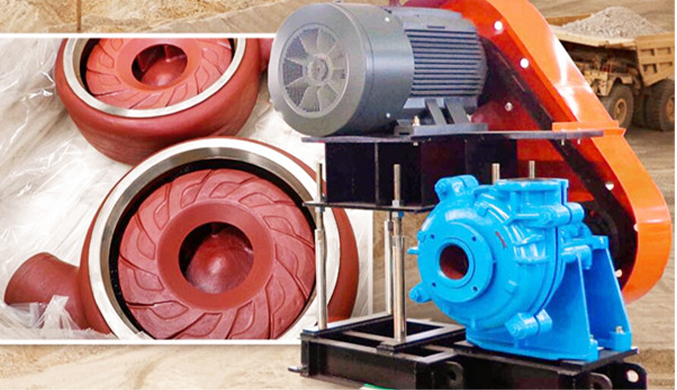

chemical processing pumps

Key Features of Chemical Processing Pumps

Several features set effective chemical processing pumps apart

- Sealing Mechanisms To prevent leaks and ensure safety, many chemical pumps employ advanced sealing technologies, such as mechanical seals, magnetic drive systems, or double seals.

- Material Selection The materials used in pump construction (such as stainless steel, Hastelloy, or PVC) are chosen based on their ability to resist corrosion and wear.

- Modular Design Many modern pumps are designed with modular components, allowing for easier upgrades and replacements as technology evolves or needs change.

- Monitoring Systems Advanced pumps often incorporate monitoring and control systems that track performance metrics such as flow rate and pressure, facilitating proactive maintenance.

Applications Across Industries

Chemical processing pumps have versatile applications across a broad spectrum of industries

- Petrochemical Industry Used for transporting crude oil, fuels, and lubricants.

- Pharmaceuticals Critical for the transfer of APIs (Active Pharmaceutical Ingredients) and other chemicals involved in drug manufacturing.

- Food and Beverage Employed to move ingredients and ensure sanitary processing of consumables.

- Water Treatment Utilized in the transfer of chemicals for purification and treatment processes.

Conclusion

Chemical processing pumps are vital tools in modern industrial applications, providing safe, reliable, and efficient fluid transfer solutions. Understanding the fundamentals of pump selection, features, and applications can significantly impact operational efficiency and safety within chemical processing environments. As industries continue to evolve and innovate, the role of these pumps in ensuring smooth and effective processes will remain indispensable. Whether you're in manufacturing, pharmaceuticals, or any field dealing with liquid transport, selecting the right chemical processing pump is crucial for success.

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025

-

pipeline pump - Chi Yuan Pumps Co., LTD.|High Efficiency&Low Noise

NewsJul.31,2025