English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 28, 2024 11:30 Back to list

Efficient Solutions for Cement Slurry Pumping in Construction and Industrial Applications

Understanding Cement Slurry Pumps A Key Component in Construction and Oil Industries

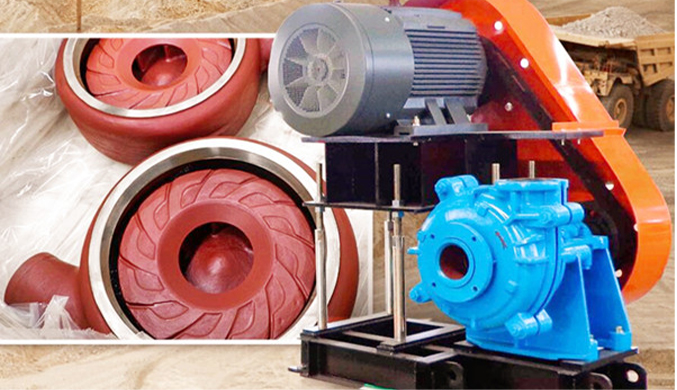

Cement slurry pumps play a vital role in the construction, oil, and gas industries, facilitating the efficient transporting of cement slurries that are essential for various applications such as well cementing, foundation work, and infrastructure development. Understanding their mechanisms, applications, and benefits can provide valuable insights for engineers and project managers alike.

What is a Cement Slurry Pump?

A cement slurry pump is specifically designed to handle the complex mixture of cement, water, and additives known as cement slurry. This mixture is often used in drilling operations for oil and gas, as well as in construction projects for foundations, void filling, and reinforcement of structures. The pump works by transferring the slurry from one location to another, enabling effective application and implementation of cement in various contexts.

Key Features of Cement Slurry Pumps

Cement slurry pumps are built to withstand the demanding conditions associated with cement handling. They are characterized by

1. High Abrasion Resistance Given the abrasive nature of cement slurries, these pumps are constructed from materials that resist wear and tear, typically using hardened alloys or rubber linings. 2. Robust Construction Cement slurry pumps must be durable to handle high pressures and varying flow rates, making their structural integrity crucial for reliable performance.

3. Versatility Many cement slurry pumps can accommodate different types of slurries, including those with a variety of additives and varying consistencies, making them suitable for a range of applications.

Applications in the Industry

The applications of cement slurry pumps extend across various fields, including

- Oil and Gas Industry In drilling operations, cement slurry pumps are used during well cementing to create a seal in the wellbore, preventing gas and other fluids from entering the well

. This process ensures the stability of the well and protects the environment.cement slurry pump

- Construction In construction, cement slurry pumps deliver material for foundation work, grouting, and surface repairs. They are essential for enabling the quick and efficient placement of concrete, thus reducing project timelines.

- Mining In mining operations, they help in the stabilization of excavations and are used in processes such as backfilling.

Benefits of Using Cement Slurry Pumps

The use of cement slurry pumps presents several advantages

- Increased Efficiency By using cement slurry pumps, construction and drilling operations can be completed more quickly and efficiently, minimizing downtime and labor costs.

- Improved Quality Control These pumps allow for precise control over the mixture and flow rate of the cement slurry, which improves the overall quality of the application and reduces the likelihood of errors.

- Enhanced Safety By mechanizing the transfer of heavy and abrasive materials, cement slurry pumps reduce the manual handling required, lowering the risk of injury to workers.

Maintenance and Care

To ensure longevity and performance, regular maintenance of cement slurry pumps is essential. This includes checking seals, bearings, and impellers for wear, as well as cleaning the pump regularly to prevent buildup of materials that could cause blockages or inefficiencies.

Conclusion

In conclusion, cement slurry pumps are integral to the success of various industrial operations, especially in construction and oil drilling. Their design and functionality cater to the unique challenges presented by cement transportation, making them indispensable tools in achieving project goals. Understanding their features, applications, and maintenance needs allows professionals in the industry to optimize performance and enhance productivity, contributing to the overall quality and safety of their operations. As technology continues to advance, the potential for improved designs and efficiencies in cement slurry pumps will only bolster their significance in industrial applications.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025