English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dec . 02, 2024 00:08 Back to list

Exploring Innovations in Pump Technology for Enhanced Efficiency and Performance

An Overview of Case Pump Technology

Case pumps are a vital component in various industrial processes, offering an efficient solution for the transportation of fluids. Their design and functionality make them suitable for a wide range of applications, from agricultural irrigation to large-scale industrial processes. This article will explore the key features, types, applications, and benefits of case pumps, providing insights into their significance in modern engineering and operations.

What is a Case Pump?

A case pump, commonly known as a casing pump or centrifugal pump, utilizes a rotating impeller to move fluids. The basic principle involves converting rotational energy, typically from an electric motor, into kinetic energy by passing the fluid through the impeller. This kinetic energy is then transformed into pressure energy as the fluid exits the pump casing. The design typically features a volute, which helps to efficiently channel the fluid flow and improve overall performance.

Types of Case Pumps

There are several types of case pumps, each suited to specific applications

1. Single-Stage Pumps These pumps have one impeller and are ideal for applications requiring low to medium flow rates and pressures. They are commonly used in agricultural irrigation or residential water supply.

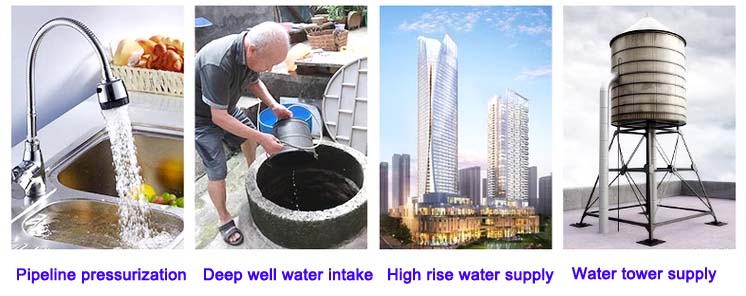

2. Multi-Stage Pumps Equipped with multiple impellers, these pumps can achieve higher pressures and are suitable for applications where increased head is necessary, such as in high-rise buildings and large-scale water distribution systems.

3. Submersible Pumps Designed to operate submerged in the fluid they are pumping, these pumps are often used in well water extraction, sewage treatment plants, and flood control systems.

4. Self-Priming Pumps These pumps can clear their air locks and start pumping without needing to be primed manually, making them convenient for various applications where fluid levels may change.

Applications of Case Pumps

Case pumps are utilized in numerous sectors, including

case pump

- Water and Wastewater Management They play a crucial role in municipal water supply systems, sewage treatment, and stormwater management. - Agriculture Farmers depend on case pumps for irrigation, ensuring proper water supply to crops in order to maximize yields.

- Chemical and Petrochemical Industries They are used for transporting chemicals and other fluids safely and efficiently.

- Food and Beverage Industry Case pumps are essential for transferring liquids during processing and bottling.

Benefits of Case Pumps

The widespread adoption of case pumps is largely due to their numerous advantages

- Efficiency Case pumps provide high efficiency rates, meaning they can transport large volumes of fluid with relatively low energy consumption.

- Durability These pumps are designed to handle a range of fluid types, including corrosive and abrasive materials, making them suitable for harsh operating conditions.

- Low Maintenance With fewer moving parts compared to other types of pumps, case pumps require less maintenance, resulting in lower operational costs over time.

- Versatility Their adaptability makes them applicable in various environments, from industrial settings to residential applications.

Conclusion

In summary, case pumps are an integral part of many industrial and agricultural processes. Their efficiency, versatility, and durability make them essential for fluid transport across a wide range of applications. As industries continue to evolve, the demand for sophisticated pumping solutions like case pumps is likely to increase, ensuring that these devices remain at the forefront of fluid dynamics technology. By understanding the diverse features and applications of case pumps, engineers and operators can make informed decisions that enhance productivity and operational efficiency.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025