English

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Oct . 04, 2024 11:54 Back to list

ah slurry pump

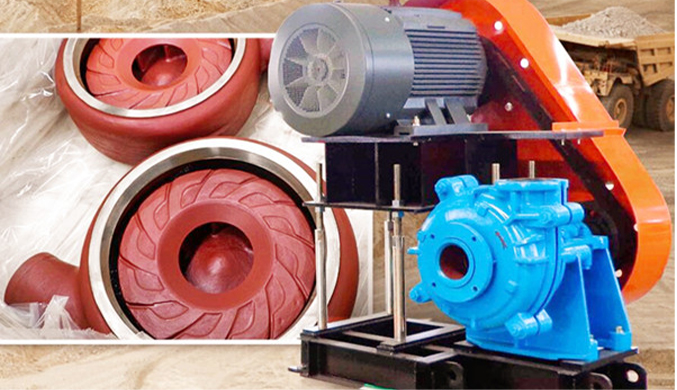

Understanding AH Slurry Pumps Key Features and Applications

AH slurry pumps are a fundamental component in various industrial processes, particularly in the mining, mineral processing, and construction sectors. Known for their robust design and efficiency, these pumps are engineered specifically for pumping abrasive and viscous slurries, which are typically challenging to handle.

Design and Construction

The AH slurry pump is characterized by its durable construction, which often includes high chromium alloy materials that resist wear and corrosion. The pump's design features a cantilevered shaft and an impeller specifically crafted to accommodate slurries containing solid particles. This design helps maintain performance levels while significantly reducing the risk of damage to the pump components. The heavy-duty frame and the application of elastomers further enhance the pump's lifespan, ensuring consistent, reliable operation under harsh conditions.

Operational Efficiency

One of the main advantages of the AH slurry pump is its ability to handle slurries with high solid concentrations without compromising on efficiency or performance. The pump typically operates using a centrifugal mechanism, which allows it to generate significant pressure while ensuring that the slurries are moved effectively through the system. The hydraulic efficiency of these pumps means they can operate with lower energy consumption compared to other types of pumps, making them both economically and environmentally advantageous.

ah slurry pump

Applications

AH slurry pumps are widely used across various industries. In mining operations, they are essential for the transportation of mineral slurries and tailings, helping companies efficiently manage their resources and waste. In the metallurgical sector, these pumps are utilized for slurry transport in processes such as flotation and leaching. Construction projects also rely on AH slurry pumps for dewatering applications and the handling of cement and grout mixtures.

Maintenance and Reliability

Another significant aspect of AH slurry pumps is their maintenance requirements. With proper care and routine inspections, these pumps can sustain prolonged periods of service, reducing the need for frequent replacements. Many manufacturers offer comprehensive support and service packages, including advice on maintenance practices and access to replacement parts, ensuring optimal performance throughout the pump's operational life.

To conclude, AH slurry pumps play a crucial role in the efficient handling of challenging materials within various industrial applications. Their robust design, efficiency, and versatility make them indispensable tools in sectors where slurries are prevalent. By understanding the features and operational mechanisms of AH slurry pumps, industries can enhance their productivity, reduce downtime, and improve overall process efficiency, contributing to sustainable and cost-effective operations. Investing in quality AH slurry pumps is not just about immediate needs but is a strategic decision for long-term operational success.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Engineering&Industrial Efficiency

NewsJul.30,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Energy Saving

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|High Efficiency&Reliable Performance

NewsJul.29,2025