Malay

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dis . 05, 2024 15:24 Back to list

heavy duty slurry pumps

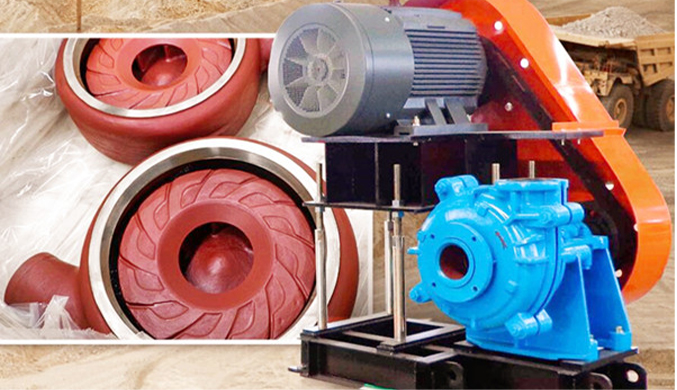

Understanding Heavy-Duty Slurry Pumps A Comprehensive Overview

Heavy-duty slurry pumps are essential components in various industries where the efficient and reliable transportation of abrasive and viscous materials is necessary. These pumps are designed to handle slurries—mixtures of liquid and solid particles—often found in mining, construction, sewage treatment, and various manufacturing processes. This article delves into the functionality, applications, types, and maintenance of heavy-duty slurry pumps.

Functionality of Heavy-Duty Slurry Pumps

Heavy-duty slurry pumps operate by moving mixtures of solids and fluids through a piping system. Their design includes features that enable them to withstand the harsh conditions often encountered in these applications. Unlike standard pumps, slurry pumps are built with robust materials to resist wear caused by abrasive particles in the fluid. They may include options such as increased impeller clearance or reinforced casings, allowing them to handle larger solid particles without compromising performance.

The mechanism behind slurry pumps is relatively straightforward. They utilize either a centrifugal or positive displacement mechanism to create pressure that moves the slurry through the system. Centrifugal pumps rely on rotational energy, produced by the impeller, to create a flow, while positive displacement pumps work by trapping a fixed volume of slurry and forcing it into the discharge pipe. The choice between these methods depends on the specific requirements of the application, including flow rate, pressure, and the nature of the slurry.

Applications of Heavy-Duty Slurry Pumps

Heavy-duty slurry pumps are widely utilized across various sectors. In the mining industry, they transport slurry from mineral processing operations, including the transportation of ore slurries, tailings, and process water. The ability to move these materials efficiently can significantly impact the profitability of a mining operation.

In the construction industry, slurry pumps are used to handle the removal of excess water and other materials during excavation and foundation work. They are also essential in the production of concrete, where water and aggregates are mixed to achieve the desired consistency.

Furthermore, wastewater treatment plants utilize heavy-duty slurry pumps to convey sludge and other byproducts of the treatment process. Their role is crucial in ensuring that treatment processes are not hindered by blockages or inefficiencies caused by thick or heavy sludges.

Types of Heavy-Duty Slurry Pumps

heavy duty slurry pumps

There are several types of heavy-duty slurry pumps, each designed for specific tasks

. The most common types include1. Centrifugal Slurry Pumps These are the most widely used pumps in the industry, favored for their efficiency and ability to handle large volumes.

2. Positive Displacement Pumps Ideal for applications requiring high pressure and precise flow control, these pumps can manage slurries with higher solid content without damaging the pump.

3. Submersible Slurry Pumps Designed to operate underwater, these pumps are typically used in applications where the slurry must be pumped from deep wells or pits.

4. Vertical Slurry Pumps These pumps are characterized by their vertical orientation, allowing them to handle high volumes of slurry while occupying minimal floor space.

Maintenance of Heavy-Duty Slurry Pumps

Regular maintenance is critical for the optimal performance and longevity of heavy-duty slurry pumps. Key maintenance practices include regular inspections, monitoring for wear and tear, and timely replacement of worn parts such as impellers and seals. Moreover, maintaining proper lubrication and ensuring that there is no buildup of solid materials in the pump can help prevent blockages and ensure efficient operation.

In addition, operators should be trained in the proper operation of the pumps. Improper handling, such as overloading the pump or running it dry, can lead to significant damage and costly repairs.

Conclusion

Heavy-duty slurry pumps play a crucial role in numerous industries by efficiently transporting complex mixtures of solids and liquids. Understanding their functionality, applications, types, and maintenance is essential for optimizing their use and ensuring smooth operational processes. By selecting the right pump for specific tasks and adhering to maintenance protocols, industries can significantly enhance productivity and reduce downtime related to equipment failure.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025