Malayalam

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

സെപ് . 12, 2024 04:14 Back to list

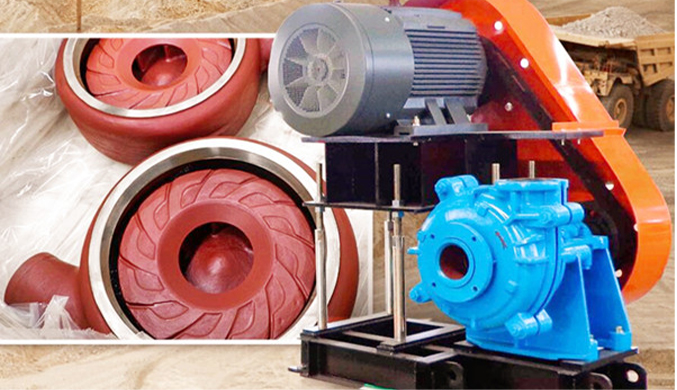

High-Performance Rubber Lined Slurry Pumps for Efficient Material Transport

Understanding Rubber Lined Slurry Pumps

In various industrial applications, proper management of abrasive slurries is crucial for maintaining operational efficiency and equipment longevity. One of the most effective solutions to handle such demanding fluids is the rubber lined slurry pump. These pumps are specifically designed to handle slurries, which are mixtures of solid particles and liquids, commonly used in mining, mineral processing, and wastewater treatment sectors.

What Are Rubber Lined Slurry Pumps?

Rubber lined slurry pumps are engineered with a unique lining made of natural or synthetic rubber materials. This design serves two primary purposes protecting the pump's metal components from the abrasive nature of slurries and reducing wear and tear over time. The rubber lining enhances the pump's ability to withstand corrosive and erosive conditions, extending its service life and reducing maintenance costs.

Key Advantages

1. Enhanced Wear Resistance The rubber lining significantly minimizes erosion and abrasion caused by solid particles in the slurry. This property not only improves the longevity of the pump but also ensures consistent performance.

2. Corrosion Resistance Slurry pumps often operate in harsh chemical environments. The rubber lining provides excellent resistance to various corrosive substances, making it suitable for handling aggressive slurries found in mining or chemical processing applications.

3. Energy Efficiency The streamlined design of rubber lined slurry pumps allows for a more efficient flow of slurries, potentially reducing energy consumption. Lower hydraulic losses translate to reduced operational costs, making the pump a more sustainable choice for industrial operations.

rubber lined slurry pump

4. Lower Noise Levels Rubber has superior vibration-dampening properties compared to metal components. As a result, rubber lined slurry pumps tend to operate more quietly, contributing to a better working environment.

Applications

Rubber lined slurry pumps are widely used in sectors such as mining, where they are responsible for transporting various types of ores, tailings, and slurry mixtures. In mineral processing, these pumps play a crucial role in moving slurry between stages of extraction, enhancing the overall efficiency of the process. Additionally, they are commonly used in wastewater treatment plants to manage sludge and other solid-liquid mixtures.

Maintenance and Care

Proper maintenance is essential to ensure the longevity and reliability of rubber lined slurry pumps. Regular inspections should be carried out to check for wear on the rubber lining, as well as other components. Scheduled maintenance can include replacing the rubber lining when necessary, ensuring seals are intact, and monitoring performance metrics to identify any anomalies early.

Conclusion

Rubber lined slurry pumps are a vital component in the movement of abrasive and corrosive slurries across multiple industries. Their unique design provides significant advantages in terms of wear resistance, corrosion protection, and operational efficiency. By investing in these specialized pumps, companies can enhance their productivity while minimizing downtime and maintenance costs. As industries continue to evolve, the importance of reliable slurry transportation solutions will remain a key focus for operational success.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025