Malayalam

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ആഗ . 30, 2024 16:15 Back to list

Expert Pumps and Pipeline Services for Efficient Fluid Management

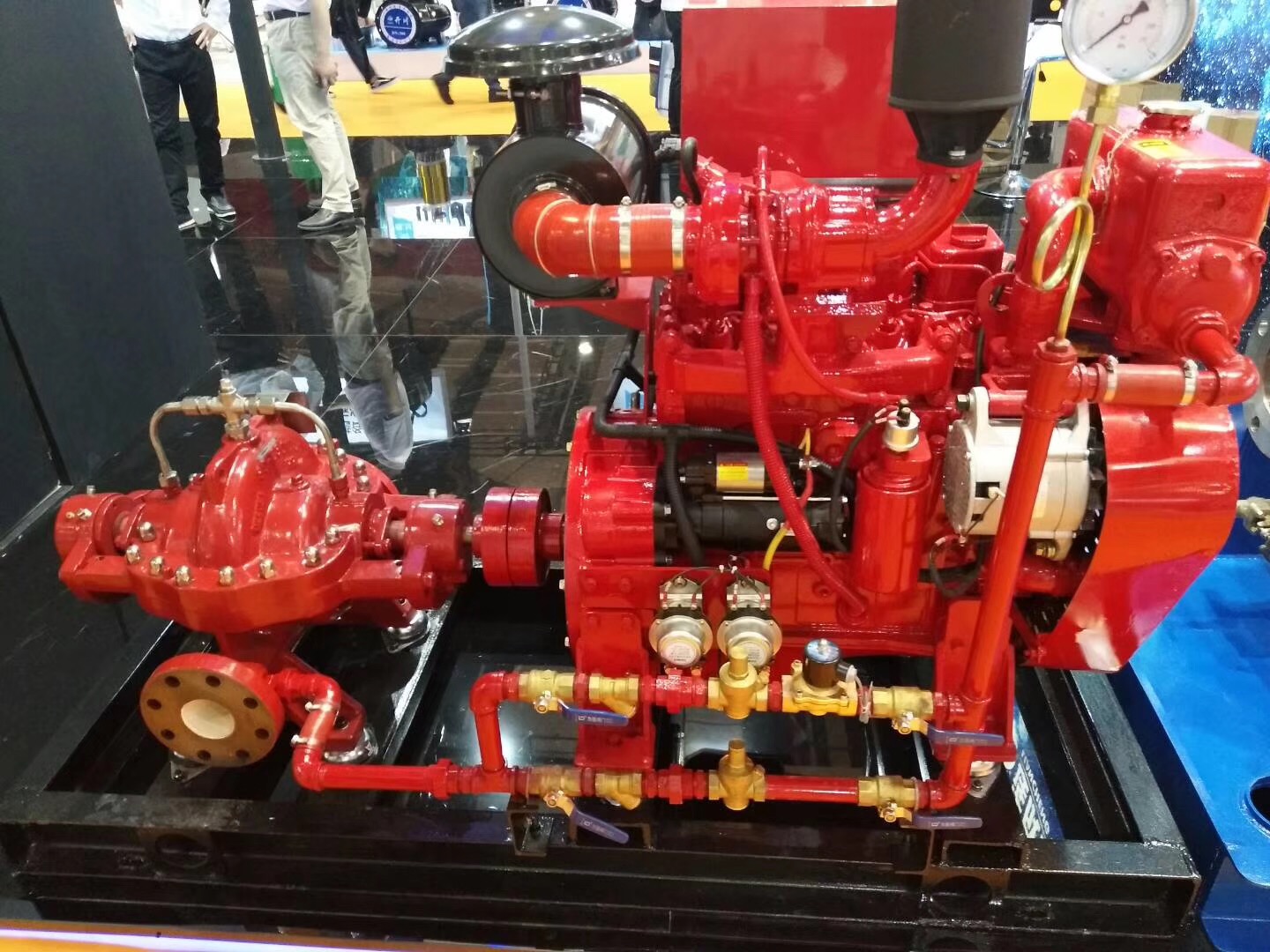

Pumps and Pipeline Services The Backbone of Industrial Efficiency

In the modern industrial landscape, pumps and pipeline services play a pivotal role in ensuring the efficient movement of fluids across various sectors, including oil and gas, water treatment, and chemical processing. These services are foundational to the infrastructure that supports manufacturing, agriculture, and power generation, making them indispensable for both operational efficiency and economic growth.

Pumps are mechanical devices designed to move fluids by converting mechanical energy into hydraulic energy. They are categorized into several types, including centrifugal pumps, positive displacement pumps, and submersible pumps, each serving specific applications. For example, centrifugal pumps are widely used in water supply and irrigation, while positive displacement pumps are favored in applications requiring high pressure or the handling of viscous fluids.

Pipeline services, on the other hand, encompass the installation, maintenance, and repair of pipelines that transport fluids over long distances. Effective pipeline services ensure that the flow of substances within these conduits remains uninterrupted and efficient. The integrity of pipelines is crucial since leaks can lead to significant financial losses, environmental hazards, and safety risks. Consequently, routine inspections, corrosion management, and robust maintenance programs are vital components of pipeline management.

One of the primary considerations in both pump and pipeline services is the choice of materials. The selection of appropriate materials for pumps and pipelines is critical to withstand the various pressures, temperatures, and chemical compositions of the fluids being transported. Advances in technology have led to the development of specialized materials that enhance durability and resistance to corrosion, thus extending the lifespan of both pumps and pipelines.

pumps and pipeline services

Moreover, the integration of modern technologies such as automation and real-time monitoring has revolutionized the management of pumps and pipelines. Automation allows for precise control of pump operations, optimizing performance while reducing energy consumption and operational costs. Additionally, real-time monitoring systems employ sensors and data analytics to track the condition of equipment and fluid characteristics. This proactive approach facilitates early detection of potential issues, minimizing downtime and maintenance costs.

Safety is paramount in all aspects of pumps and pipeline services. Industry standards and regulations are in place to ensure that operations are conducted safely, minimizing the risk of accidents and environmental damage. Regular safety training for personnel involved in these services is also essential, promoting a culture of safety that permeates every level of operation.

The demand for efficient pumps and pipeline services is expected to grow as industries increasingly focus on sustainability. The shift toward environmentally friendly practices, including the adoption of renewable energy sources and improved waste management, will necessitate innovative fluid handling solutions. As such, companies are investing in research and development to create more energy-efficient pumps and smarter pipeline systems.

In conclusion, pumps and pipeline services are integral to the seamless operation of various industries. As technology advances and the demand for efficiency and sustainability grows, these services will evolve, offering innovative solutions that address the challenges of fluid transportation. Ensuring their reliability and safety will remain a top priority, ultimately contributing to greater productivity and minimal environmental impact in the industrial sector.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025